About Splitting Batches

The Split functionality lets you divide a process or tank batch into two or more new batches. Any existing flow constraints defined on the process step are taken into consideration. If splitting the batch will result in a violation of one of the constraints, you will be prompted to confirm if you want to continue or to cancel.

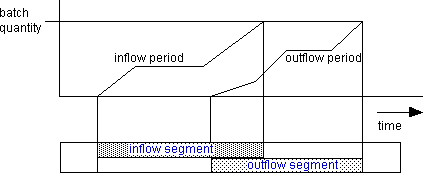

You need to know that a batch has inflow and outflow segments. During these segments, there is product flow into and out of the batch.

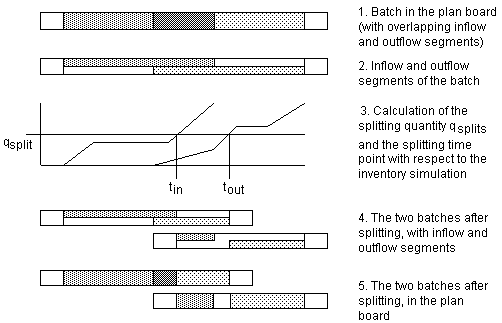

Inflow and outflow do not have to occur in parallel or at the same rate. Furthermore, for an incompletely scheduled batch, the inflow quantity is smaller than the outflow quantity. When splitting, both the inflow and outflow is split in the same way. This is because the new batches need both inflow and outflow. The figure illustrates how the splitting is calculated.

From the splitting quantity, tsplit, the time points tin and tout on which the segments are split are calculated. If the inflow quantity is less than the splitting quantity, the end of the inflow is taken. In contrast, if one of the splitting time points is known, then both the quantity and the time point can be calculated for the other segment.

If a duration d is entered, this is first converted into a point in time using the equation tout= start + d, and the above method is then applied.

The point at which you split the batch must be in the inflow or outflow segment of the batch. The end time is calculated from the beginning of the original batch. Infor Production Scheduling ensures that the inflow and outflow are mutually consistent and that they are not excessively long. The various values that you can enter are calculated from the batch duration. This may lead to inaccuracies, because duration is always rounded off to whole minutes.