About Process Steps

A process step is the recipe for one main product in a specific stage. The process step:

- Lists inflow products that feed into the stage to which the process step belongs and describes which resources are used to make (and to store) this particular product.

- Enables batch scheduling by providing information about the following: methods, batch sizes (minimum, maximum and standard quantity), and factors such as rate, standing time, inflow duration, filling duration, minimum standing time, initial rate, filling level, buffer time and changeover criteria.

- Can also result in a number of by-products.

Finding Process Step to Process Step Relationships

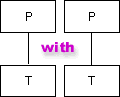

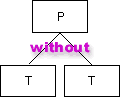

Select one process step in the overview window by selecting . Then click the or buttons to display process steps that provide inflow to and receive outflow from your selection. Search results are presented in the order of the product flow.

These tabs are displayed in the Process step entry window:

- General: Allows you to specify the general information about the process step.

- Constraints: Allows you to define the restrictions and specifications for the process step.

- Resource Groups: Allows you to select the resource groups for the process step.

- Inflow Products: Allows you to define inflow products.

- By-products: Allows you to define by-products of this process step.

- Resource Claim: Allows you to update any existing resource claims.

- Utility Claim: Allows you to update any existing utility claims.

- Transition: Allows you to define changeover by defining transition matrices and transition rules.

- Custom Fields: Allows you to specify the value for the custom field.

- Product variants: Allows you to specify the product variants of the process step. The Product variants tab is only visible for the process steps with couple stages.

- The and options are available only for the users who are assigned the Modeler role.

- The and options are enabled only if a process step is unlocked or locked.

- You cannot modify a

process step that is locked. However, you can duplicate a process step using

the

option even if the selected step is locked.

option even if the selected step is locked.

- The option is enabled only if the selected process step is unlocked.

Use the

( )

option to print a process step report.

)

option to print a process step report.