Sequencing - Standard

In standard sequencing type, you can optimize operation sequences to improve production scheduling. The benefits carrying great weight are increased resource utilization and reduced setup times. The Planning application provides a large number of functions within this area (manual and automatic optimization, automatic sequencing steps for cyclic, oven and batch size optimization). This concept in particular deals with the basic methods of optimizing operation sequences.

One of the most important goals of production scheduling is to utilize the facility's most critical resources (bottlenecks) optimally. Efficient scheduling of these resources ensures the company a continued high rate of productivity.

When collecting original operations and placing them in sequence one right after the other (sequencing) overall setup times can be reduced. Towards this end a special feature in the Planning application makes it possible to schedule and optimize operations in a sequence.

The Sequence Optimization Controls and Automatic Simulation components provide special tools to automatically optimize resources, avoid gaps in the schedule and utilize the company's capacity in the best manner possible. The Scheduling Board component provides special tools to sequence optimize resources manually.

Position

The decision of whether or not to use the sequencing functionality can be based on the production requirements in the facility. These requirements are typical for situations where sequencing may be beneficial:

- Production on bottleneck resources should be increased, mainly through minimization of setup times

- Production costs related to material waste or setup time should be reduced

- Possible higher quality piecework from operators

The task of operation sequence optimization takes place in the Scheduling process in-between the Solving External Supplies and Solving Bottlenecks sub-processes.

Results

Proper use of Sequencing - Basic Methods can lead to these results.

- Primary Result

The understanding of the basic methods of sequencing gives the opportunity to gain benefits from the sequencing tools provided by the Planning application.

- Usage

- Possibility to improve delivery capability

- Possibility to obtain a production schedule where reduction of lead times and increase of resource utilization has reached an optimum balance

- Increase production on bottleneck resources through minimization of setup times

- Reduce production costs related to material waste or setup time

- Obtain higher quality piecework from operators

- Changes in

Infor M3

BE

The process of optimizing the sequence of operations has great effect on the delivery times for the effected manufacturing orders (MO). Changes made to any MO are included when exporting the schedule to Infor M3 BE.

Prerequisites

Before Sequencing - Basic Methods can be used these prerequisites must be met: A fundamental understanding of Planning and Scheduling processes and techniques must have been acquired

Basic methods of sequencing

Sequencing is determined to re-schedule operations in such a way that their sequence is optimized towards minimization of setup times and maximization of resource utilization.

Sequencing can be conducted in two different ways: manual sequence optimization and automatic sequence optimization. The manual form is conducted entirely by the user while the automatic form is conducted by the Planning application according to parameter settings made by the user. Manual sequencing is based on one simple method while automatic sequencing can be based on several different methods that span from simple to advanced.

Manual sequencing

Conducting sequencing manually means that the user directly changes the sequence of operations. This is done in the Scheduling Board component where the user can manually shift operations, alter the operation status and check potential results. In the Scheduling Board it is also possible to calculate the accumulated setup time for a selected number of operations. The setup time can then be compared to the new accumulated setup time after the operations have been optimized manually.

When an operation sequence is satisfactory, the user can apply sequence status 17 (sequence locked) to the operations. Sequence status 17 will retain the manually optimized operation sequence during the next scheduling process.

All adopted changes will be taken into consideration in the following Automatic Simulation.

Automatic sequencing

Automatic sequencing is controlled by settings in the Sequence Optimization Controls component where sequencing steps are defined. These types of sequencing steps are available:

- Standard

- This step type is used to define the order in which operations should be optimized and planned based upon the user's experiences.

- Minimize setup time

- This step type is used to determine in which sequence the operations should be optimized and planned focused on minimizing setup times.

- Oven

- Steps of the oven type are used to conduct sequence optimization on work center resources defined as an oven, that is, in a ceramic oven where a group of operations are taken in and out simultaneously.

- Cyclic

- The cyclic step type is used to minimize setup times according to a repeated profile pattern. For example, a cyclic step type can be set up to raise and lower the shade of colors according to a profile pattern (for a molding machine).

- Batch-sizing

- This step is used to adjust batch sizes of orders according to the resource capacities. For example, if the fixed batch size is set to 100, the batch-sizing function collects operations with equal grouping part of the co-sorting key until a quantity as close to 100 as possible is reached. For example if two operations of 50 and 40 are collected into a sequencing group the original order quantity is 90, but the produced batch size is 100. This means that a surplus of 10 is to be distributed among the parent orders.

The descriptions and examples in this concept document are based upon the Standard step type.

The sixth sequencing step: Forward Order Scheduling

There is a sixth sequencing step type which stands aside the five others: Forward order scheduling. This sequencing step type is different in that way it conducts a forward scheduling step with no sequence optimization included. For example, when two bottleneck work centers have sequence optimized operations, and in-between there is a work center that is not a bottleneck, then it is appropriate to define a forward order scheduling step in-between the two sequence optimization steps. This provides a correct plan, because it ensures that the second sequence optimization step is based upon calculation of new setup times, which again is based upon operation start and end times after the first sequence optimization.

Automatic sequencing is conducted in the Automatic Simulation component after locking the operation sequence and before forward scheduling. These settings control the automatic sequencing process:

- Sequencing control

- Sequencing horizon (default or defined per sequencing step)

- Operation start time control

- Whether or not scheduling should continue at same secondary resource within each new sequence group

- Whether or not operations are allowed to overlap one another during sequencing

After sequencing the resource and the order of individual operations is locked according to sequencing status 15 (applied in automatic sequence optimization) and sequencing status 17 (according to manual sequence optimization).

Basic elements in sequencing

This section gives a brief description of the basic elements used in order to make automatic sequence optimization of operations possible.

- Co-sorting key. The co-sorting key is used for grouping and sorting operations and is the key to control sequencing. First part of the co-sorting key (grouping part) is used to collect operations with similar properties (size, color, etc.) into sequence groups. The second part of the co-sorting key (sequencing part) is used to sort or group the operations within each sequence group.

- Setup time matrix. Each record in the setup time matrix specifies the setup time between two operations on a work center resource. The standard setup times are retrieved from these resources. The earliest start time for the operation is used when searching for setup times in the matrix.

- Sequencing status. Sequencing status indicates the current status for sequence optimized operations. The status can be Active (status 10), Sequenced (status 15), Sequence locked (status 17) or Locked (status 20). The Scheduled resource field shows the specific resource on which the operation is locked.

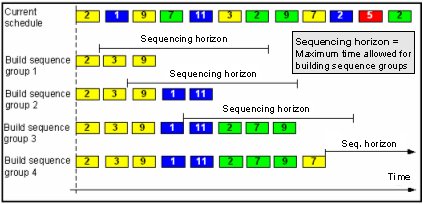

- Sequencing horizon. Sequencing horizon determines the number of working days used for the operation sequence optimization. All operations, with a scheduled end time that is earlier than the calculated horizon, are candidates for being sequence optimized. The sequencing horizon can be defined by a default value (set in the Initial Step during Automatic Simulation) or a specific value (the Redefine sequencing horizon field) defined for each sequencing step. If a specific value is defined on a sequencing step, the default value is overruled.

- Sequencing priority. The sequencing priority controls the sequence in which the resources including sequenced operations are scheduled. The sequencing priority should be defined to reflect the normal production flow. When the sequence optimization is done the sequenced operations will be assigned sequencing status 15 and these operations will be scheduled during the Initial Step in Automatic Simulation. Operations assigned to the resource with the lowest sequencing priority are scheduled first, and operations assigned to the resource with the highest sequencing priority are rescheduled last.

The next section describes how these elements are used in sequencing.

The main goal: Balancing lead time and resource utilization

The main benefit of sequencing is an improved delivery capability together with an efficient balance between lead time and capacity utilization in concrete situations. Such a situation could be, for example, that the normal production capacity and delivery capability changes with seasonal demand and variations.

Sequencing involves creating a balance between lead times and resource utilization. Even though sequencing gives significant advantages in attaining an optimal schedule, special attention must be paid to possible undesirable consequences. Contingent on the circumstances, these consequences could include:

- Prolongation of lead time. If sequencing is applied to large time horizons, then single operations have the possibility to be moved far ahead in time. This may result in longer lead times on particular orders.

- Orders produced too early or too late. Related to the possible prolongation of lead times (or the movement of entire orders), single orders may be produced earlier than required (increasing stock expenses) or later than required (decreasing delivery capability).

- Inappropriate flow between resources. When optimizing the utilization of one resource this might create a situation where the utilization of another resource is decreased. Also the optimization of operation sequence on one resource could make it more difficult to optimize resources that follow it. For example, operations scheduled on different work centers may overlap even though they belong to the same order. This may result in starting a demanding operation before the supplying operation is finished.

The balancing act of optimizing lead time and resource utilization at the same time is illustrated by an example in the next section.

In addition to balancing lead time and resource utilization, it should be secured that operations occurring prior to the bottleneck are scheduled before the bottleneck itself is prioritized and scheduled. This is especially important if these operations control the earliest start time on the bottleneck and in this way also control the time frame for optimization on the bottleneck.

Example of balancing lead time and resource utilization

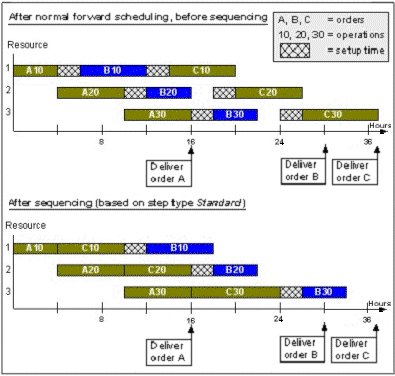

This example is based on a Standard sequencing step. Three orders (A, B and C) each having three operations (10, 20 and 30) are scheduled on three different resources (1, 2 and 3). After a normal forward order scheduling the operations are scheduled from the earliest possible start time and forwards. In this case all orders can be delivered on time, but it also entails gaps in the schedule for the resources 2 and 3.

The coloring of the operations indicates the way in which they can be sequence optimized, that is, operations with the same color can be collected in order to save setup time. After sequencing has been conducted, operations belonging to orders A and C are now scheduled after each other. This saves 2 hours of setup on each resource. Another benefit is that the gaps have been removed from the schedule, which means the resource utilization has increased. But there should also be paid attention to the changes for order B. The lead time for order B has increased and it will no longer be delivered on time.

How a schedule is sequence optimized (Standard)

When the Sequence Optimization Controls component is activated, its reference point is taken from the current active schedule that is created by forward scheduling. See Automatic Simulation. In this schedule, the order of operations is controlled based on their priorities and available capacity. During sequencing the order of operations is changed in such a way that setup times are minimized and production thereby increases. The sequencing function includes these activities:

- Build sequence groups

- Optimize operations within sequence groups

- Calculate setup times

The descriptions in the following subsections are entirely based upon the definition of a sequencing step of Standard type.

Build sequence groups

An operation can be part of a sequence group if it:

- Has the same grouping part of the co-sorting key

- Has the relevant resource in its own work center

- Has the forced resource on a resource that has to be optimized

Sequencing collects groups of operations with duplicate grouping parts of the co-sorting key in those cases where changes to the co-sorting key involve increased setup times. Scheduling operations in a group right after each other reduces setup time.

Sequencing also takes note of the maximum size of each group, the order of operations within a group and the treatment of possible gaps in the schedule.

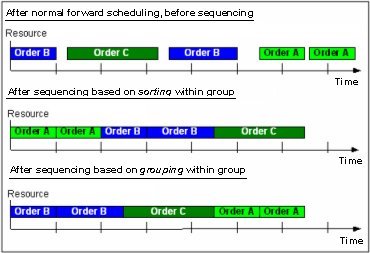

Optimize operations within sequence groups

Sequence groups are collected based on the grouping part of the co-sorting key. Next they can be sorted or grouped on the sequencing part of the co-sorting key. Choosing when best to sort or group on the sequence part of the co-sorting key depend on the relevant scheduling situation. The difference between sorting and grouping on the sequencing part of the co-sorting key is illustrated in this example:

Forward scheduling could appear as follows for a given sequence of operations collected using the grouping part of the co-sorting key. The letters represent the arrangement of the orders co-sorting keys.

By grouping instead of sorting on the sequencing part of the co-sorting key, you can sometimes avoid (as in this example) pulling some operations too far forward which causes delay of other operations.

Calculate setup times

On the work center resource is defined the way in which setup time is calculated and whether setup time is obtained from the operation, the resource or a combination thereof. Both standard and reduced setup times can be assigned to each respective operation.

Setup time for current operations is always calculated as it relates to the previous operation. In addition, calculation of setup time is carried out on operations, which fit into these categories:

- The operation is the first in a sequence group

- The operation within a sequence group is in progress (operation status 50) or locked (sequencing status 20)

- The operation is within the locked sequence horizon and is in progress (operation status 50) or locked (sequencing status 20)

Thus, locked operations are taken into account when calculating setup time and changes in subsequent scheduling are prevented. In this way all operations are planned with correct setup times.

Special conditions related to sequencing

Even though significant advantage using sequencing can be attained there are circumstances where this optimization may not be beneficial. These circumstances are listed below:

- Situations where sequencing should be avoided

- Situations where sequencing demands special attention

- Special considerations regarding lead time

Situations where sequencing should be avoided

Sequencing should be avoided in these situations:

- The possibility of reducing setup times on the resource is minimal or non existent

- Clarification of the best order of a series of operations takes place as an integrated part of the production process (for example, it is done by the operators)

- There is no buffer time in the production process (buffer time should be at least the same as the sequencing horizon)

- A bottleneck resource is defined as a Fill-up resource

Situations where sequencing demands special attention

This section contains tips that may help when parameters for sequencing are defined.

-

Large number of operations with equal grouping part of the co-sorting key.

If there are many operations with the same grouping part of the co-sorting key, the orders with the last sequence optimized operation will have prolonged lead times. You can limit this effect by defining realistic values for the parameters: Maximum time allowed for grouping and Maximum operation time within group.

-

Work centers with multiple resources.

If you sequence optimize a work center and it contains more than one resource, all operations in a sequence group will be scheduled on that resource and the operation that comes first will have the earliest start time.

-

Sequencing horizon must be defined.

The most common reason operations fail to be sequence optimized is that the sequencing horizon (represented in days) has been omitted. This parameter is defined in the Initial Step during Automatic Simulation and calculated based on the schedule start time.

-

Operations depending on order delivery date.

It needs careful attention when sequence optimization is conducted on a resource where one or more operations depend on an order delivery date. The delivery date establishes boundaries for the earliest start date for the first operation in the order, which can result in gaps in the use of the resource. You can limit this problem by setting the parameters Gap control and Maximum gaps allowed within groups.

-

Sequencing on more than one resource at a time.

If sequence optimization is conducted on more than one resource at a time a sequencing step with forward scheduling should be placed between each work center optimization. Moreover, if an order uses more than one work center, it is also necessary to define a sequencing step between optimizations of each work center.

-

Operations without operation time.

If you have operations without operation time (time = 0), sequencing can give an erroneous picture. This is because these operations are placed in the schedule at the schedule start, even though their respective resources are not available at that point. The sequence horizon is calculated based on operation end time, which in this case is the schedule start time.

-

Special Considerations Regarding Lead Time.

Special attention should be given to changes in lead time if:

- Scheduling is conducted using Pull-up after sequencing. (Refer to the concept Pull-up Parameters for more detail.)

- Material synchronization is conducted between two sequence optimizations on two different levels in the network, such as finished goods and intermediate goods. See Material Synchronization.

Advanced sequencing methods

Although the basic methods of sequencing (Standard sequencing step, forward scheduling and manual optimization) involve a number of potential improvements towards an optimized schedule, they are not always sufficient to solve any kind of sequencing problem. The Planning application provides several advanced sequencing methods, which are described in separate concept documents.

- Batch Size Adjustments. Used for adjusting batch sizes automatically when optimizing operation sequence on resources that produces orders in fixed batch sizes.

- Cyclic Sequence Optimization. Used for optimizing resources where the sequence of operations follows a certain pattern that can be repeated.

- Oven Scheduling. Used for optimizing resources that can handle several operations at the same time.