Sequencing - Cyclic

Cyclic sequence optimization is an advanced way to set up the automatic optimization of operation sequences more flexibly. The cyclic step type is used to minimize setup times according to a repeated profile pattern. For example, a cyclic step type can be set up to raise and lower the shade of colors according to a profile pattern (for a molding machine).

The task of cyclic sequence optimization takes place in the Scheduling process after Solving External Supplies and before Solving Bottlenecks.

The understanding and use of Sequencing - Cyclic Sequence Optimization result in:

- Primary Result

Decreased setup times according to a repeated profile pattern of operation sequence

- Usage

- Changes in

Infor M3

BE

The process of optimizing the sequence of operations has great effect on the delivery times for the effected manufacturing orders (MO). Changes made to any MO are included when exporting the schedule to Infor M3 BE.

Before Sequencing - Cyclic Sequence Optimization can be used, these prerequisites must be met:

- A fundamental understanding of the Sequencing - Basic Methods concept must have been acquired.

- The prerequisites stated in the Sequencing - Basic Methods concept must also be met.

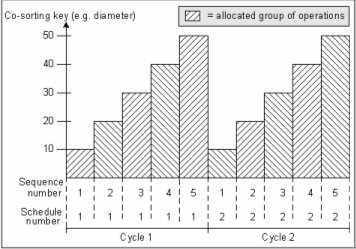

Cycle, schedule number and sequence number

A cycle consists of a number of groups in which operations with equal grouping part of the co-sorting key have been collected. Each group has a sequence number and within one cycle they all have the same schedule number applied. The allocated groups of operations will be sequence optimized in the order determined by the sequence numbers.

The schedule number is used in all work center resources included in sequence optimization. The first operation (i.e., the operation applying the earliest start time) that is not yet optimized initiates the sequence optimization cycle. The initial schedule number is calculated by 1 plus the largest schedule number that is used among the included sequence locked operations.

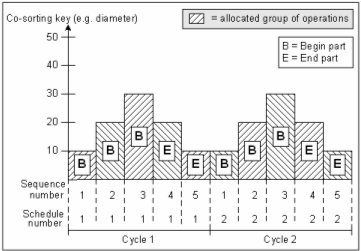

Profile pattern

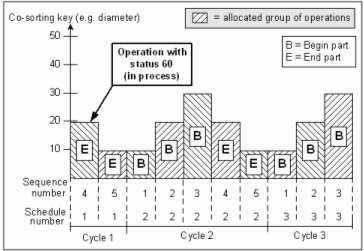

The profile pattern can consist of two types of profile parts, a Begin part and an End part. Using begin and end parts of a profile is convenient if the co-sorting key can both be raised and lowered within a cycle, e.g. the temperature of an oven. This is illustrated by this diagram:

Note: It is only necessary to define End parts for a profile if the Balancing function is used.

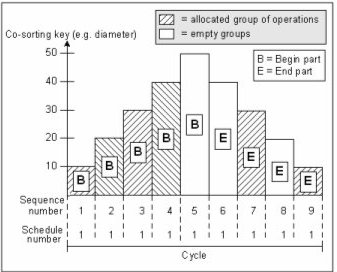

Balancing and threshold

Balancing is used to define the maximum number of allocated groups in begin and end parts of the profile. An allocated group is a group with at least one planned operation. A balanced profile must be symmetric, i.e. the allocated groups in the Begin part of the profile must be mirrored in the end part.

Balancing is only used if the difference in number of allocated groups is greater than the balancing threshold value. The threshold controls whether a difference in number of allocated groups between begin and end parts should be considered during sequence optimization. The threshold value determines the size of the difference where the action of balancing is executed. For example, if the difference in number of allocated groups in the Begin and End parts is 2 (there are two more allocated groups in the begin part than in the end part) and the threshold value is set to 3, then no balancing will be done. If the threshold value is 2 then balancing will be done.

In the next diagram, there are 4 allocated groups in the begin part of the profile (sequence number 1, 2, 3 and 4), and only 2 allocated groups in the end part (sequence number 7 and 9). If the threshold parameter is set to 2 (or lower) the balancing will take place.

The allocated groups will be moved from the large to the small part. (In this case from the begin part to the end part.) The groups that are being moved will be the ones with no counterparts. (In this case the groups with sequence number 2 and 4.) The criteria for moving allocated groups are as follows:

- Allocated groups will be moved from the part with the largest number of groups

- Movements are done from the center of the profile

- The first group (counted from the center) is always moved

- Only every second group is moved. (Otherwise the largest number of groups will just have been moved to the other part of the profile and the imbalance would not have changed.)

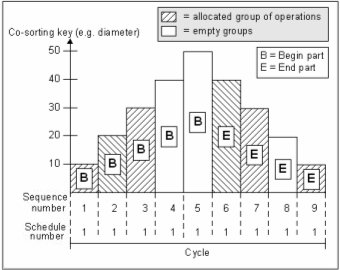

In the example shown above, the group with sequence number 4 will be moved as this is the first group. The group with sequence number 2 will not be moved as this is the second group counted from the last moved group. This results in this profile:

The group with sequence number 4 is now empty and the group with sequence number 6 is filled. The profile is now in balance with 3 groups in each part.

Maximum time allowed for grouping

The operation grouping process is assigned a maximum time for completion. An operation is associated with one group only if the difference between planned start for the operation and planned end for the earliest (first) operation in the group is not larger than Maximum time allowed for grouping.

Group minimum and look-ahead horizon

A Look-ahead factor can be used to define a look-ahead horizon. The look-ahead horizon is created by multiplying the look-ahead factor by the Maximum time allowed for grouping. This extended period is used to fill sequence groups with a number of allocated operations lower than Group minimum. Sequence groups within the maximum time allowed for grouping and with a number of operations lower than or equal to the defined Group minimum will be increased with additional operations from the look-ahead horizon. No operations are added to any groups in which the number of operations is higher than the Group minimum. Operations are only added until the group minimum is exceeded. The remaining operations within the look-ahead horizon will not be included in scheduling until the next cycle or later.

Example:

This example is based on these settings:

| Maximum time allowed for grouping: |

48 hours |

| Group minimum: |

2 operations |

| Look-ahead factor: |

10 |

Two sequence groups within the Maximum time allowed for grouping have one operation allocated. Three operations within the look-ahead horizon (10 * 48 hours = 480 hours) are not allocated to any group. In this case, the two sequence groups each with one operation, will have one additional operation added. The third operation will not be allocated to any group because all groups within the Maximum time allowed for grouping now respect the Group minimum.

Include empty groups

Groups with no allocated operations can be included or not. This is controlled by the parameter Include empty groups. If this parameter is activated, groups with no operations are considered as lower than group minimum. This means they will be filled with operations within the look-ahead horizon and be closed when no more operations are found within this horizon. If the parameter Include empty groups is not activated the empty groups are ignored and no operations will be added.

Processing of operations in process

Cyclic sequencing respects operations that are in process. According to this the selection of which operation that will be first in the sequence is depending on whether there are operations within the sequence that are in process (operation status > 60). This means that the sequence of operations will not necessarily start at the beginning of a cyclic sequence profile pattern. See this example:

In the example shown above, an operation with sequence number 4 and schedule number 1 has operation status 60 (in process). Of this reason the cycle has to begin with an End part of the defined profile pattern. The result is that cycle 1 is shorter than cycle 2 and a cycle 3 needs to be created. This is done automatically by the system.

Spool file for cyclic sequencing

A spool file logging functionality can be activated. This will tell you in detail what happened during the cyclic sequence optimization. As sequence optimization is a part of the initial step in automatic simulation, the log information will be written in the SCHA spool file.