Sequencing - Oven

In this sequencing type, users are able to understand how to treat resources where a multiple number of operations can be manufactured at the same time, that is, oven resources, and how such operations can be included in Sequencing.

For example, these resources could be part of a paint factory. On oven resources groups of operations are scheduled to begin and end at the same time.

The task of oven scheduling takes place in the continuation of operation sequence optimization, that is, in the Scheduling process after Solving External Supplies and before Solving Bottlenecks.

The understanding and use of Sequencing - Oven Scheduling result in:

- Primary Result

Optimized operation sequences on oven resources

- Usage

Oven scheduling lets sequence optimization include resources that can handle multiple operations simultaneously

- Changes in

Infor M3

BE

The process of optimizing the sequence of operations has great effect on the delivery times for the effected manufacturing orders (MO). Changes made to any MO are included when exporting the schedule to Infor M3 BE.

Before Sequencing - Oven Scheduling can be used these prerequisites must be met:

- A fundamental understanding of the Sequencing - Basic Methods concept must have been acquired

- The prerequisites stated in the Sequencing - Basic Methods concept must also be met

Oven scheduling

Oven scheduling means a collection and scheduling of operations from different orders on the same resource. In this way, the operations receive the same start and end times. Oven scheduling consists of both sequencing and normal forward order scheduling steps.

Oven sequencing

Sequencing on the oven resources is carried out automatically in a sequencing step by setting group control parameters for the oven scheduling. Operations with equal grouping part of co-sorting key are collected into a sequence group, though the maximum on a resource is given by the group maximum defined in the resource registry.

You can also oven schedule manually in the Scheduling Board. See the section entitled, How to conduct oven scheduling in the Scheduling Board.

Forward order scheduling of ovens

Sequencing most often happens using the short-term horizon. The remaining parts of the operations are scheduled using the normal forward order scheduling. In forward order scheduling operations are scheduled individually and placed one right after the other. Here, it is important that the resource is loaded with the correct capacity so that the delivery dates will be calculated realistically.

To be certain the oven resource is loaded correctly in forward scheduling, a modified operation time is calculated. This calculation is conducted based on this expression:

| Modified operation time | = | Original operation time | X | Scheduled nr. of opr. /opr. Quantity /opr. Time |

| Max oven load X Average load % |

Example of oven scheduling

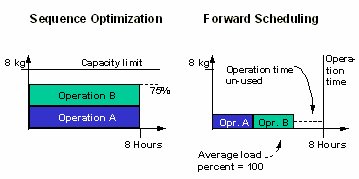

In this example, an oven resource with a daily run time of 8 hours and a maximum capacity of 8 kg is used. During sequencing, two operations (A and B) scheduled on the oven, each have 3 kg of capacity and 8 hours of operation time. Since the remaining capacity is only 2 kg, there is not enough capacity for a third operation to take place. The average load percent is set to 100%. The capacity load and the duration of the operation on the resource is displayed as follows:

As shown above, sequencing applies a realistic capacity load to the operations, while forward order scheduling shows available capacity that in fact does not exist. This can result in overbooking of resources, especially in the long term.

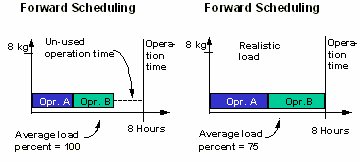

The average load percent in the example is 100%. Forward order scheduling does not show a real of the loading because some operations fill more after they are sequenced. To ensure there is a correct load of capacity, the average load percent is assigned to the capacity load expected, that is the value is set to 75% (6 kg of a total capacity of 8 kg has been used).

Here after the duration of the operation changes such that the load shown in forward order scheduling will be the same as that which can in reality be produced in the oven.

As the operation is modified in forward order scheduling, the turnaround time for individual orders will be shorter than is realistic and in this way show earlier delivery times. Defining the parameter oven buffer time control compensates for the effect.

Oven buffer time control

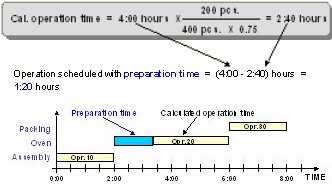

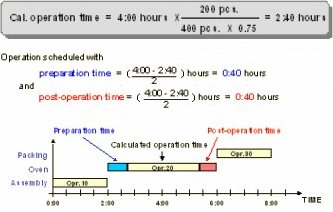

The parameter for buffer time is explained based on an example with these values:

Operation time: 4:00 hours

Operation quantity: 200 pieces

Oven load U/M Operation quantity

Maximum oven load: 400 pieces

Average load percent: 75.00

Oven buffer time control in oven scheduling can be defined in one of these three ways:

-

Adjustment of preparation time. If adjustment of preparation

time is chosen, the difference between the original operation time and the

modified operation time will be defined as preparation time. Note: This

parameter will overrule the corresponding times defined on the resource.

Oven Buffer Time Control - adjusted as preparation time:

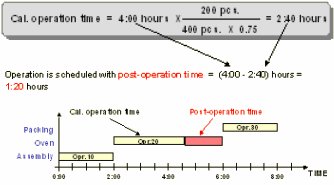

Adjustment of post-operation time. If the post-operation time is adjusted the difference between the original operation time and the modified operation time will be defined as post-operation time.

Buffer Time in Oven Scheduling - adjusted as post-operation time:

- Both adjusted

equally.

If preparation time and post-operation time are both adjusted the difference between original operation time and modified operation time will be divided equally between preparation time and post-operation time. The parameter will take precedence over other definitions on the resource.

Buffer Time in Oven Scheduling - adjusted as preparation and post-operation time

Conducting oven scheduling in the Scheduling Board

Oven scheduling using the Scheduling Board is a half-automated process. After automatic simulation is conducted, operations can be adjusted manually by using the oven scheduling function in the Scheduling Board. To do this use these steps:

- Transfer operations to list. Operations to be oven scheduled are transferred to a manual order scheduling list in the Scheduling Board.

- Define a calculated value. For example, weight or volume for chosen operations. Note: The calculated value is for information purposes only and can be used as an indicator for how much of a resources capacity is taken up by the chosen operations. For example, if you know that the oven has a capacity of 5000 pieces, the calculation sum for the operations can not exceed 5000. If the calculation sum does exceed 5000 you will have to remove some of the operations.

- Choose operations to oven schedule. The operations on your list are scheduled with the same start and end time point. All operations receive status 20 (locked in time) and are scheduled on top of each other. Click the spot on the Scheduling Board the operation should start.

- Unlock oven scheduled operations. If you regret oven scheduling you can unlock the operations again by choosing the operations in the Scheduling Board. The unlocked operations will receive status 10. At this point it will be necessary to carry out another order scheduling to take the changes into account.

Example of a typical oven scheduling

This example shows a typical scheduling which includes oven scheduling:

- Forward scheduling. The first step is automatic scheduling of all orders contents. Operations on oven resources are scheduled together and will therefore have the same start time.

- Manual sequence optimization of operations on the oven resource. The second step is sequence scheduling of operations on resources defined as oven resources. The purpose here is to collect alike operations on the same resource.

- Oven Scheduling. The third step is oven scheduling. Sequenced operations are scheduled on the oven resources via the Scheduling Board. All operations receive the same start time and status 20.

- Forward scheduling. The automatic order scheduling is carried out again to be certain operations are scheduled correctly.

Defining an oven resource

When a resource is defined as an oven resource in the Planning application it is based on the ceramic oven principle. In this principle all operations are carried out at once within specified period of time. This principle is the opposite of the pizza oven principle where operations are placed on the resource at overlapping times and in random succession.

When a resource can handle many orders at once, it is important that there is neither too much nor too little capacity reserved on the resource and that even capacity level is maintained. To establish this balance, orders are put in and taken out in groups and the total oven capacity is defined.

An oven resource is defined by defining parameters in the order they appear below:

- Loading principle. Set to the oven option.

- Oven load U/M. Defines the oven capacity (group maximum) unit of measure. There are three possible units:

- Number of operations

- Operation duration

- Operation time

- Maximum oven load. Gives the amount of capacity available on a resource after each process has been completed. The unit of measurement applicable to this capacity parameter is defined in oven load U/M.

- Average load percent. Defines how much the resource is expected to be loaded on the average. The information is included in the calculation of modified operation time that secures the correct duration of the operations. Because small operations are easier to combine in order to fill the oven in the best way possible, the smaller the operations, the higher AFP can be given. If there is an order which has a grouping part of co-sorting key that is seldom used, the oven will not be able to be filled and a lower average load percent will be given.

When to use oven resources

Generally, if a resource can handle a multiple of operations at the same time, it is suitable as an oven resource.

If the resource can only sometimes be scheduled as an oven resource, you can use the half-automatic oven function in the Scheduling Board.

When to avoid using oven resources

Certain orders can not be scheduled on a resource defined as an oven resource. Oven scheduled operations can not:

- Be a secondary operation

- Be a primary operation with secondary operations

- Have alternate operations