Criteria to measure Overall Equipment Effectiveness

The criteria considered to measure equipment effectiveness:

-

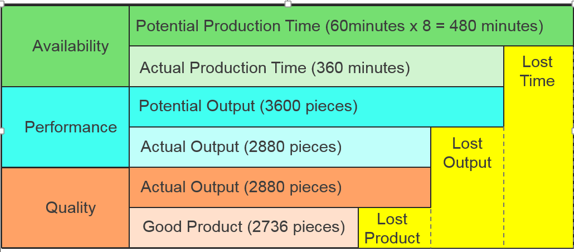

Availability

The machines available time for production. That is the potential production time and actual production time.

-

Performance

The machines performance rate. That is the potential output and actual output.

-

Quality

The machines quality rate. That is the actual output and the output that meets the specification.

Example

Based on the above example OEE calculation is as follows:

Availability rate: The potential production time of 480 minutes. Due to downtime of the machine, the actual production time is 360 minutes.

The machine's availability rate is 360 minutes (actual) / 480

minutes (potential) * 100 = 75%

Performance rate: For the actual production time, the potential output is 3600 pieces. Due to performance loss the actual output is only 2880 pieces.

The machine's performance rate is 2880 pieces (actual) / 3600

pieces (potential) * 100 = 80%

Quality rate: For the 2880 pieces that are actually produced, only 2736 pieces meet the required specifications.

The machine's quality rate is 2736 pieces (as per standard) /

2880 pieces (actual) * 100 = 95%

The lost time, lost output and lost product are considered for OEE calculation consequently:

Overall Equipment Effectiveness = Availability x Performance x Quality