Outbound data

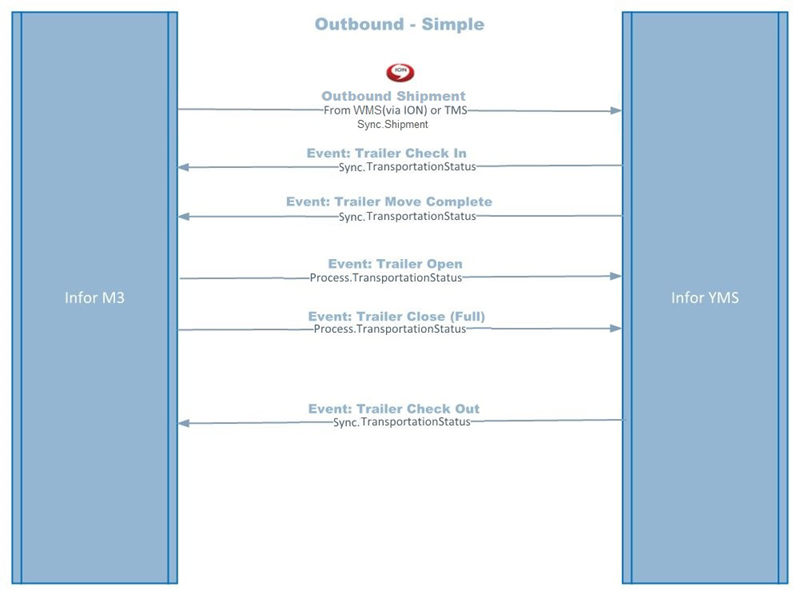

The outbound data flow is the flow of BODs that are centered around the outbound shipping process. Equipment arrives at the facility to be loaded, which is typically indicated by an outbound shipment. This diagram shows a simple outbound flow between the two systems.

Like the inbound flow, the outbound flow shows the shipment order sent to Infor YMS followed by the equipment activities centered around the outbound shipping process.

This table shows the BODs that fall into the outbound data category.

| BOD | Description |

|---|---|

| Sync.Shipment | This BOD provides Infor YMS with the inventory that is being shipped or loaded prior to the equipment departing from the facility and is a critical link between WMS or ERP and Infor YMS. This information is key in the operational process of determining inventory that has been loaded onto equipment and the precedence for departing that equipment from the facility to achieve key milestone date requirements. |

| Sync.TransportationStatus | YMS is the System of Record (SOR) of equipment because Infor YMS is maintaining the

status location and processing of the equipment while it exists within the boundary of the

yard. Infor YMS provides the WMS or ERP system with this information:

The general flow of equipment is shown in the simple data flow example, which visually illustrates the events that are triggered by Infor YMS. |

| Process.TransportationStatus | Like in the inbound data flow, the Infor YMS knows when equipment both arrives and departs from a door or unload point, the physical opening and closing of the equipment doors are events that are typically known by the WMS or ERP system, and if possible, should be communicated to Infor YMS to keep the two systems synchronized regarding the real time loading status of the equipment. The WMS or ERP systems can also utilize the Process.TransportationStatus BOD to request equipment type to be brought to a loading point. |

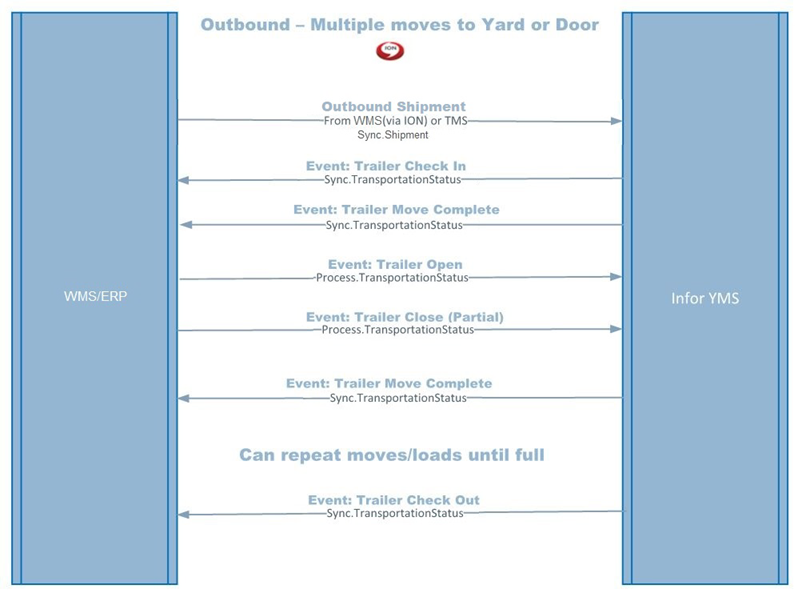

This diagram shows an example of a complex outbound scenario.

The only difference in this example is that the equipment is not completely loaded when it is first brought to the door or unload point. The only change to the BOD is the data that indicates partial loading, while the general flow of BODs does not change.