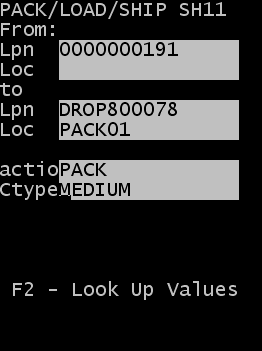

Using the Pack/Load/Ship screen

To use the Pack/Load/Ship screen:

Note:

- The Labor Std screen is displayed with these details after

packing is completed:

- Actual Time

- Std Time

- Performance

- The Timesheet screen captures and records labor standards for all the packing functions. You can access the Timesheet screen from the menu at the level.