Performing load tasks on RF devices

To perform load tasks on an RF device.

-

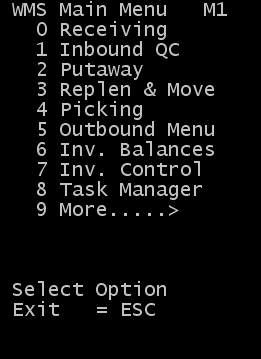

From the RF device

Main menu, select

Outbound Menu.

-

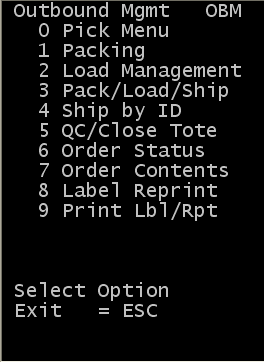

Select

Load Management.

-

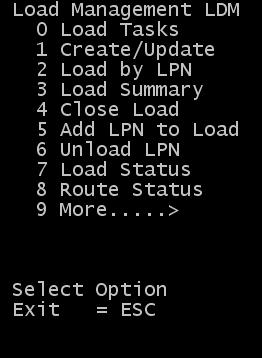

The Load Management

(LDM) menu is displayed. Select

Load Tasks.

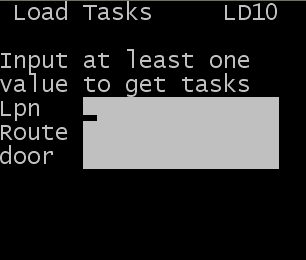

The Load Tasks (LD10) screen is displayed to start retrieving load tasks.

Note: If the Labor Module within the SCE application is enabled and you did not select to start work, a message indicating that you need to start work before continuing is displayed. See the Infor WMS Productivity and Labor User Guide for information on starting and stopping work.

-

Specify this information to begin getting and loading tasks:

- Lpn

- License Plate, Case ID, or Drop ID of the picked product to be loaded. Valid LPNs available for loading can be found in the Outbound Units tab of the Load Management screen.

- Route

- Route code for a load record in the system. If route is used to initiate the tasks, the system suggests a license plate based on the stop assigned to the orders (normally in reverse stop sequence).

- Door

- Valid door number assigned to a load record in the system. If the door is used to initiate tasks, the system suggests a license plate based on the stop assigned to the orders (normally in reverse stop sequence).

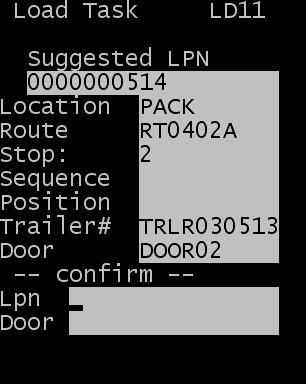

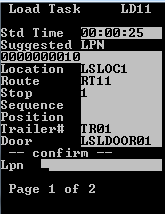

- The Load Task (LD11) screen is displayed with load task information.

-

If the SCE Labor module is enabled, the standard time for the task is displayed on the screen.

-

Confirm the load task:

- Lpn

- Suggested license plate or another license plate for the same

stop. If the operator attempts to load a license plate for a different stop,

the following message displays:

No loading tasks found for the Id on the current stop. - Door

- Door number assigned to the load. If the operator attempts to

confirm the license plate to a different door, the following message displays

preventing the task from completing:

Either the Door or the ID confirmation failed. Press Y to try again. - The suggested ID can be overridden only if the:

- New ID represents an outbound Movable Unit on the same stop

- System setting

option

Allow RF Override is selected.

If the Load Sequence field is set to No Restrictions, the alternate ID scanned by the loader does not have to be on the same stop as the suggested ID.

- If the Allow RF Override option is disabled, you receive an error message if you scan an ID other than the suggested one. An error message also displays if an invalid door is entered.

- When the first task for a load is completed, a Drop ID is created with an ID identical to the Load ID. All of the tasks on the Drop ID are considered child IDs. To view the task details in the application, select Execution > Productivity > Drop ID.

- Temp

- If the item is configured to require a temperature reading, you are prompted for an entry on the next screen. Specify the temperature of the load.

- Floor Loaded

- Select Y for Yes to specify that the contents of the license plate were physically placed on the floor of the trailer and are no longer part of a license plate. Otherwise, specify N for No.

-

To complete the load transaction, press

Enter. The system remains

on the

Load Task (LD11) screen until all open tasks for

the current stop are completed.

Note:

- If the load sequence field is set to Stop Sequence, or Reverse Stop Sequence, the application automatically dispatches a task for the next stop to be loaded.

- If the Load sequence field is set to Stop Group or No Restrictions, the application returns to the RF Loading screen, where the loader must enter the area, route, ID, or door to retrieve the next task.

-

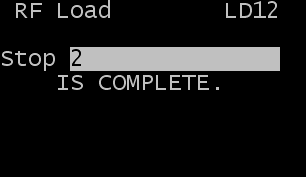

When the current stop is complete, the

RF Load (LD12) screen is displayed.

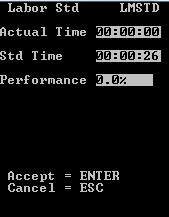

If the SCE Labor module is enabled, the task performance information is displayed.

- To continue the process and load the next stop, click Enter.

-

When all loading tasks have been completed, the following message

displays.

- The load can now be shipped.