Performing cycle counts – item by location

-

From the RF device Main

menu, select

Task Manager. The

Task Manager (TMM) is displayed.

Note: If the Labor Module within the SCE application is enabled and you did not select to start work, a message indicating that you need to start work before continuing is displayed. See the Infor WMS Productivity and Labor User Guide for information on starting and stopping work.

-

Specify this

information:

- Area

- Area in which the operator is working

- Task

- By selecting Cycle Count, you restrict the task user to receiving cycle count tasks only.

-

-

Press

Enter. If applicable, the

application sends the first cycle count task to the associate. The

Cycle Count (TCC1) is displayed.

If the SCE Labor module is enabled, the standard time for the task is displayed on the screen.

Note: The upper part of the screen is read-only; however, you can edit the lower part of the screen.

Note: The upper part of the screen is read-only; however, you can edit the lower part of the screen. -

Press

Enter. If applicable, the

application sends the first cycle count task to the associate. The

Cycle Count (TCC1) is displayed.

If the SCE Labor module is enabled, the standard time for the task is displayed on the screen.

Note: The upper part of the screen is read-only; however, you can edit the lower part of the screen.

Note: The upper part of the screen is read-only; however, you can edit the lower part of the screen. -

Specify this

information:

- Item

- Item code counted.

- Loc

- Location being counted.

- Qty

- Quantity counted for count.

-

-

Press

Enter.

The application determines the result of the count according to cycle class variances assigned to the item. If no cycle class is assigned, no cycle class variances go into effect. The application determines whether the item being counted has a Discrepancy Adjustment Rule other than Standard.

If the count does not match the application quantity and it is within variance, and has a Discrepancy Adjustment Rule other than Standard, the following message displays.

If the count does not match the application quantity and it is not within variance and has a Discrepancy Adjustment Rule other than Standard, one of the following messages displays, depending on whether the count was under or over the variance.

- To exit any of the above messages, press Esc. The application returns to the Cycle Count screen.

- If applicable, repeat the count by entering modified values.

-

To generate new

inventory currently not in the system, press

F3.

When prompted, enter Location and LPN of the inventory to be added. The system then checks whether or not the entered LPN already exists in another warehouse location.

If LPN only exists in one location, the system then validates whether the inventory is in Allocated status, HOLD, or neither.

-

Allocated

If the location is Allocated, the following message displays:

Inventory already exists in location XXX. This inventory is allocated therefore it cannot be added or moved.

A cycle count record is then created and displayed in the Cycle Count Maintenance screen for the counted inventory.

- TheCycle Count Header and Cycle Cont Detail will be (4) Location Mismatch.

-

Cycle Count Detail Notes field displays:

Inventory already exists in location XXX. This inventory is allocated therefore it cannot be added or moved.

-

HOLD

If the location is on HOLD, the following message displays:

Inventory already exists in location XXX. Location XXX is on HOLD therefore inventory cannot be added or moved.

- TheCycle Count Header and Cycle Cont Detail will be (4) Location Mismatch.

-

Cycle Count Detail Notes

field displays:

Inventory already exists in location XXX. Location XXX is on HOLD therefore inventory cannot be added or moved.

- Not Allocated and Not

HOLD

If inventory is neither on Hold or Allocated, the following messages displays:

Inventory exists in location XXX. System is moving inventory to correct location.

If LPN exists in multiple locations the following messages displays:This LPN is in multiple locations. See your supervisor.

If the LPN does not exist:- A receipt screen displays so new inventory can be entered.

- This screen will bypass the Receipt Validation for RF Receiving - Item not on ASN.

- The system checks the lottable validation assigned to the item. Appropriate fields display, including catch weight/data and serial numbers, for capturing inventory.

-

Allocated

-

After the final count of

a location, press

Esc to finish the task.

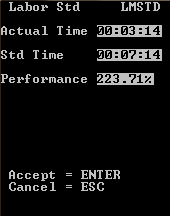

If the SCE Labor module is enabled, the task performance information is displayed.

-

To retrieve the next

task, press

Enter. The following

message displays if it is true:

-

To exit from the message

and count all lots and LPNs, press

Esc.

The application displays the cycle count tasks for the item and location that was miscounted at the Lot by Location by LPN level.