Receiving finished goods

Once the production process begins, finished goods inventory is eventually packaged and ready for receiving. The receiving process not only creates inventory for the finished good product, it also initiates the shipment of inventory for component items that are configured to use backflush logic.

To start the receiving process:

-

Select

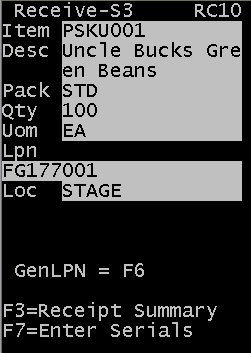

Receiving from the Prod Mgmt (POMP) menu. The Receive-S3 (RC10)

screen is displayed.

- Specify the item number for the finished good product on the first screen.

-

Specify this critical information for the license plates produced

to perform the pick:

- Qty

- Specify the quantity to receive. The quantity specified must correspond to the UOM entered for the receipt. If you are receiving one full standard pallet of the item, the entry can be 1 if the UOM is "PL". This can be populated as needed as long as the quantity entered relates to the unit of measure.

- Uom

- Specify the unit of measure corresponding to the quantity entered. This must be a valid UOM for the Pack designated for the item.

- LPN

- Specify the license plate for the item being received.

- Loc

- Specify the location to receive the finished goods.

- Lot Attributes

- Any lot attributes configured for the item are displayed for the user to confirm during the finished goods receipt. These attributes are used to determine the system lot number.

As each pallet is received for the finished good, the system automatically ships inventory for component items defined for backflush. Below is an example of how the system updates.- Total Quantity Expected for Finished Good Item = 900

- Item COMPA Quantity expected to be needed = 325 (component rate is 0.3611 per unit of FG). This ratio can be seen as the Component Qty on the order detail after the production order is allocated.

- FG Quantity Received on License Plate = 100

Results on Order/Pick Detail information:- COMPA - Initial Pick Detail has QTY = 325 (this could be multiple pick records)

- When FG Qty=100

received, COMPA is updated

- New pick created in Shipped status with Qty = 37 (0.3611 * 100, rounded up to the next whole number)

- Reduction of quantity for other pick to 288 (325 - 37)

This process continues until all of the finished goods are received.- It is possible that the entire quantity expected is not produced. If this occurs, there are excess components still allocated since the backflush would not occur for all of the expected units. The overage is maintained as part of the close process.

- It is also possible that more finished goods are produced than was expected. If this occurs, the quantity of the components shipped is automatically increased as part of the backflush process according to the ratio provided.

Unlike normal orders, the production shipment order will not be updated to shipped status until the user chooses to perform the Close process. The Production Close Process Required to Ship selection on the order header prevents the order from being updated to "shipped" status when all of the quantity expected for each component is shipped. The production order is instead updated to Close Production status so updates can continue through the end of the entire receiving process.

Note: If overages are possible, the speed line location must contain more inventory for each backflush component than the initial quantity on the original production order.