Starting dynamic picking

Once component inventory has been dropped at the production staging area using replenishment, the production process can begin. Items that are configured to use actual consumption with soft allocation will need to be picked and shipped out of Infor WMS inventory as they are consumed.

To start dynamic picking:

-

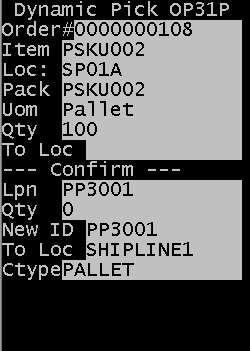

Select

Dynamic Pick from the Prod Mgmt (POMP) menu. The Dynamic Pick

(OP31P) screen is displayed.

- Specify the appropriate speed location in the Loc field to initiate the pick. The system issues the first pick from that location to the user.

-

In the Confirm portion of the screen, specify this information:

- LPN

- Scan or specify a valid license plate for the item that is currently in inventory within the Speed Line location.

- Qty

- Specify a quantity of zero (0) if you want to pick the entire license plate. You can also enter a specific license plate quantity to pick if it is less than or equal to the quantity on the license plate.

- New ID

- If picking the entire license plate (Qty = 0 as described above), scan the license plate for this ID also. If you are not picking the entire license plate, you must use a different number (such as the order number).

- To Loc

- The location you are picking to. The best method to ship the inventory is to have a location configured with the Automatically Ship Picked Product setting selected. This will allow the license plate to be shipped as the pick is completed, quickly reducing inventory and updating the production order with the actual consumption information.

- Ctype

- A carton type can be specified for the pick if desired. For

the production order process, the field can be hidden from the user since it

does not provide specific value to this part of the operation. As each pick is

completed, the following activities occur.

- A pick record is created with the license plate in shipped status.

- Inventory balances are updated to reflect the quantity that has been shipped.

- Replenishment priorities may be modified by the system if the pick has reduced the quantity in the speed line location below the Minimum Quantity level set for the item in the location.

Note: The system is not automatically issuing picks to the user. It is expected that the user is physically monitoring the production process to request a pick as more product is needed for production.