Performing an assisted cycle count by item and location

-

From the Cycle Count

menu, select

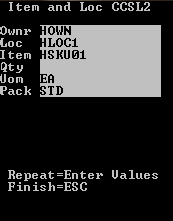

Item and Loc. The

Item and Loc screen (CCSL1) is displayed.

Note: If the Labor Module within the SCE application is enabled and you did not select to start work, a message indicating that you need to start work before continuing is displayed. See the Infor WMS Productivity and Labor User Guide for information on starting and stopping work.

-

Scan or specify this

information:

- Loc

- Location being counted.

- Item

- Item code.

- Qty

- Count quantity.

- Uom

- Defaults to EA (Each). You can change the unit of measure if the quantity specified is in a different UOM format. For example, you can record the count in cases instead of eaches.

- Pack

- Defaults to STD. You can change the default to record the quantity count and unit of measure using a different pack code.

- To confirm a location is empty, press F4.

-

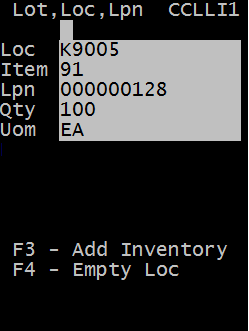

To generate new

inventory currently not in the system, press

F3.

When prompted, enter Location and LPN of the inventory to be added. The system then checks whether or not the entered LPN already exists in another warehouse location.If LPN only exists in one location, the system then validates whether the inventory is in Allocated status, HOLD, or neither.

-

Allocated

If the location is Allocated, the following message displays:

Inventory already exists in location XXX. This inventory is allocated therefore it cannot be added or moved.

- A cycle count record is then created and displayed in the Cycle Count Maintenance screen for the counted inventory.

- The Cycle Count Header and Cycle Cont Detail will be (4) Location Mismatch.

-

Cycle Count Detail Notes field displays:

Inventory already exists in location XXX. This inventory is allocated therefore it cannot be added or moved.

-

HOLD

If the location is on HOLD, the following message displays:

Inventory already exists in location XXX. Location XXX is on HOLD therefore inventory cannot be added or moved.

- The Cycle Count Header and Cycle Cont Detail will be (4) Location Mismatch.

-

Cycle Count Detail Notes

field displays:

Inventory already exists in location XXX. Location XXX is on HOLD therefore inventory cannot be added or moved.

- Not Allocated and Not

HOLD

If inventory is neither on Hold or Allocated, the following messages displays:

Inventory exists in location XXX. System is moving inventory to correct location.

If LPN exists in multiple locations theThis LPN is in multiple locations. See your supervisor.message is displayed.If the LPN does not exist:- A receipt screen displays so new inventory can be entered.

- This screen will bypass the Receipt Validation for RF Receiving - Item not on ASN.

- The system checks the lottable validation assigned to the item. Appropriate fields display, including catch weight/data and serial numbers, for capturing inventory.

-

Allocated

-

To submit the count to

the application, press

Enter.

- The application determines the result of the count according to cycle class variances assigned to the item. If no cycle class is assigned, no class variances go into effect. In addition, the application determines whether the item you are counting has a discrepancy adjustment rule other than Standard.

- The application

determines the result of the count according to cycle class variances assigned

to the item and the cycle count validation rule defined for the item.

Based on the settings, the following message can display:

If the Item Cycle Count Discrepancy rule set to STD – Count by Details - The count matches system inventory. The message displays to the associate and the count is logged. No additional input is required.

- The count does not

match system inventory and is outside the tolerance level for the item's cycle

class. The message displays to the associate and the count is logged.

- The associate can re-count.

- If the discrepancy still exists, the associate is directed to count by all LPN details. (see #5 from list below)

- The discrepancy is logged and must be maintained on the workstation.

- The count does not

match system inventory but is within the tolerance level for the item’s cycle

class. The message displays to the associate. The associate can re-count.

- The associate can re-count.

- If the discrepancy still exists, the associate is directed to count by all LPN details. (see #5 from list below)

- The system performs an inventory adjustment if the count is within a defined tolerance level.

If the Item Cycle Count Discrepancy rule is set to something other than STD and allows for automatic adjustment rules:- The count matches system inventory. The message displays to the associate and the count is logged. No additional input is required.

- The count does not

match system inventory and is outside the tolerance level for the item’s cycle

class. The message displays to the associate and the count is logged.

- The associate can re-count by item and location. (see #4 from list below)

- The discrepancy is logged and must be maintained on the workstation.

- The count does not

match system inventory but is within the tolerance level for the item’s cycle

class. The message displays to the associate.

- The associate can re-count. (See #4 from list below.)

- If a discrepancy still exists, the system performs the adjustment based on the cycle count discrepancy rule assigned to the item.

When the Count Discrepancy message displays, the associate must now count by detail records instead of item and location.This is an example of count by details:

-

To exit the message,

press

Esc. The

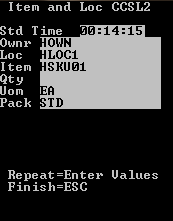

Item and Loc (CCSL2) screen is displayed,

allowing you to re-enter the count or finish the current count.

If the SCE Labor module is enabled, the standard time for the task is displayed on the screen.

-

Perform one of the

following:

- To submit a different count, update the Qty field and press Enter to Repeat.

- To complete the current count, press Esc. Adjustments are made in the system depending on tolerance settings and the quantity variance counted.

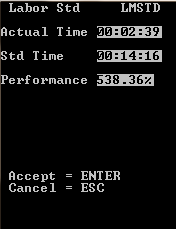

If the SCE Labor module is enabled, the task performance information is displayed.