WM bin assignments picking priorities

Bin locations are defined in terms of storage capacity, such as length, width, and height measurements, and unique storage capabilities. Generally, a location should balance available space with replenishment activity needs.

For example, suppose two locations are identical in size. You can put 100 sleeping bags in one location and 1000 waterproof bags in the other location. On an average day you sell 80 sleeping bags and 50 waterproof bags. This means you must replenish the sleeping bags daily to keep up with demand. Moving the sleeping bags to a larger location would make sense, even though sleeping bags and waterproof bags are related products.

A bin location must be defined as a certain type so the system can determine how to handle the bin location. Plan bin assignments to accommodate your material flow. Bins are initially assigned in WM Bin Location and Product Setup, but may be changed later. This list includes typical bin assignments and their descriptions:

- Primary: The primary bin is the main storage location for a product. It is used for picking and may be replenished when product is received or when it contains less than its minimum quantity. A product can have only one primary location.

- Alternate: Alternate bins are secondary locations that are often used to replenish the primary location. A product can have many alternate locations, each one with its own pick priority.

- Open: Open bins are assigned or unassigned. An assigned open bin has product assigned to it. An unassigned bin does not have any products assigned. If you use random storage or FIFO picking, open unassigned bins are used. Each bin can have its own pick priority.

- Single: Single bins are used with products that have a single location that does not change. A product that is stored in a single bin cannot be stored in any other bin. Single bins, unlike primary bins, do not have any related open or alternate bins for the same product.

- Staging: Staging bins are used for temporary storage. For example, products are stored in a staging area until back orders are filled. You can store more than one product in staging bins, regardless of your administrator options. Products are always picked from staging bins first.

- Unavailable: Unavailable bins store products that need to be repackaged, repaired, or sent back to the vendor. You can store more than one product in this type of bin.

Picking priorities

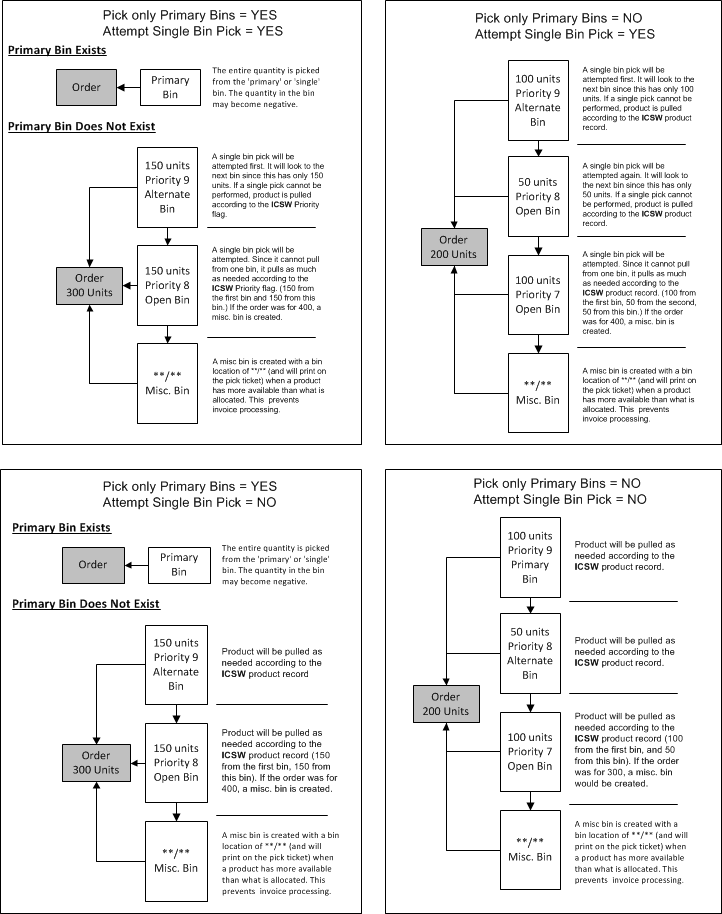

SA Administrator Options-Products-Warehouse Manager controls the priority in which bins are picked for primary, single, alternate, and open bins.