Triggering on counters

Triggering maintenance based on counters can only be done on tool and machine asset types, where the asset usage, such as machine cycles or production volume, can be counted. Where possible, this method allows maintenance to be scheduled at precisely the required moment before the asset fails or breaks down. This can help increase the reliability of assets and reduce the overall amount of required maintenance.

Using the counter frequency and the estimated number of counts per day, MES is able to accurately schedule the maintenance work.

The system estimates when maintenance will be due by dividing the counter frequency by the estimated daily counts. For example, if the maintenance threshold is 1,000 pieces and the asset produces 100 pieces per day, the procedure is theoretically due every 10 days.

However, this is a theoretical schedule. To maintain accuracy, a background process runs daily and reviews the actual counts recorded over the past week and aggregates them by asset and day. Using the actual production data, the system compares scheduled maintenance dates with real usage. Depending on outcome of the analysis, the system may move the planned date forward (to a sooner date), or move the planned date back (to a later date).

For example, if the asset reaches the usage threshold earlier than projected – for instance, exceeding 1,000 pieces on day 8 instead of day 10 – the system adjusts the maintenance schedule accordingly. The work initially planned for day 10 is moved forward to the current day, and subsequent maintenance dates are recalculated based on this updated information.

Or, for example, if the asset usage is predicted reach the threshold later than projected – for instance, reaching 1,000 pieces on day 12 instead of 8 – the system adjusts the maintenance schedule accordingly. The work initially planned for day 10 is moved back to day 12 and subsequent maintenance dates are recalculated based on this updated information.

The system allows the actual usage to be at most 25% move or less than the estimated daily average. This means the system will not move the planned dates until the actual counts are more than 25% different than the estimated counts.

As more counts are recorded over time, the accuracy of the forecast improves.

Examples

Planned dates moved forward

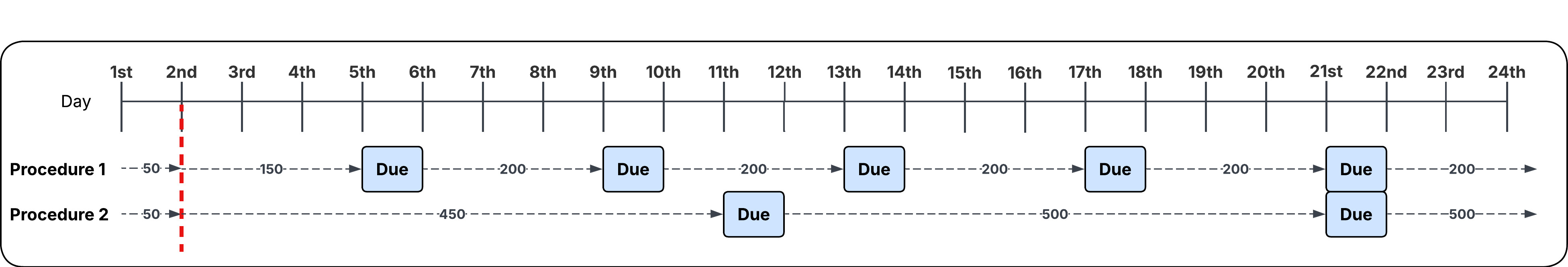

This example shows the timeline for two procedures scheduled on a single asset. Both procedures are triggered based on counts.

- Procedure 1 is scheduled every 1,000 counts with an estimated 100 counts recorded per day. The system schedules maintenance work for the 11th, 21st and so on.

- Procedure 2 is scheduled every 2,000 counts with an estimated 100 counts recorded per day. The system schedules maintenance work for the 21st and so on.

If on day 8, the actual counts exceeded the estimated counts, the schedule is updated to the following:

- Procedure 1 is triggered on day 8 instead of 10 because it reached 1,000 counts on that day. The system reschedules the maintenance work for the 8th, 15th, 22nd and so on.

- Procedure 2 is moved forward to day 15 because the actual daily counts are higher than the estimated daily counts. The system reschedules the maintenance work for the 15th and so on.

Planned date moved backwards

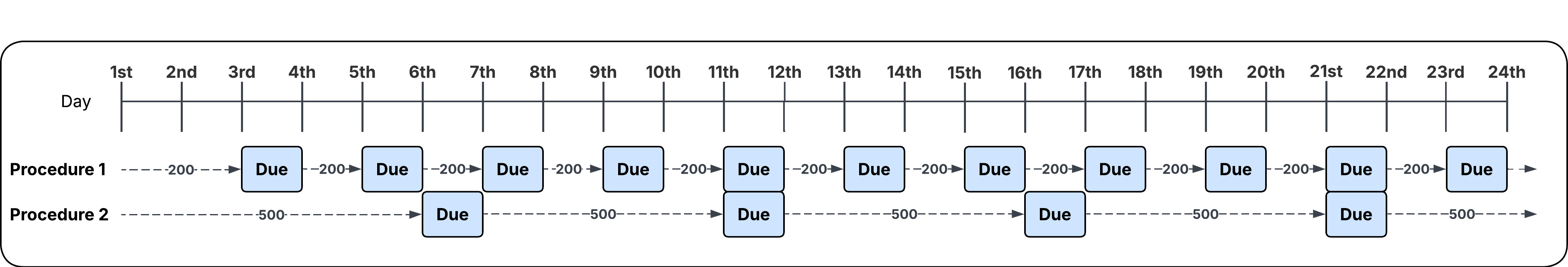

This example show the timeline for two procedures scheduled on a single asset. Both procedures are triggers based on counts.

- Procedure 1 is scheduled every 200 counts with an estimated 100 counts recorded per day. The system schedules maintenance work for the 3rd, 5th, 7th, 9th, 11th and so on.

- Procedure 2 is scheduled every 500 counts with an estimated 100 counts recorded per day. The system schedules maintenance work for the 6th, 11th, 16th, 21st and so on.

If on day 2, the actual counts were only 50, instead of the estimated 100, the schedule is updated to the following:

- Procedure 1 is moved back from day 3 to day 5 because the actual daily counts are lower than the estimated daily counts. The rest of the procedure’s schedule is also moved back accordingly.

- Procedure 2 is moved back from day 6 to day 11 because the actual the daily counts are lower than the estimated daily counts. The rest of the procedure’s schedule is also moved back accordingly.