Scheduling of Stop orders

- If the order is a stop order, which means it requires the resource to stop and be available during maintenance, the operations transferred from M3 BE are planned as secondary operations on the maintenance resources in the Planning application.

- In automatic simulation, the operations are forward planned with the primary operation first and then the secondary operations, in relation to the primary operation.

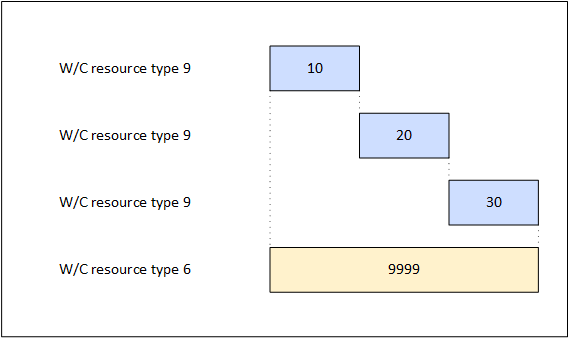

Example

The operations 10, 20, and 30 are scheduled as secondary operations on three different maintenance work center resources type 9. A pseudo-operation 9999 is created and scheduled as the primary operation on the work center resource type 6. The duration of the pseudo-operation is the sum of the operations 10, 20, and 30.

This image shows the scheduling of maintenance stop orders:

The secondary operations are scheduled with overlap code 10. The start time of the first secondary operation is the same as the start time of the primary operation, without any leading transit times. The next secondary operations are scheduled with an overlap base calculated as the sum of the operation time for the proceeding secondary operations, plus the sum of the transit times on the proceeding secondary operations, except from the first secondary operation.

Only the operations on resource type 9, which are transferred back to M3 BE pseudo-operation on the work center type 6, are used in the Planning application for the purpose of a correct planning procedure.

If the order is not a stop order, which means the resource does not have to stop during maintenance, the operations are only scheduled on the maintenance resources type 9. You can then view the load on the maintenance resources, but you cannot put any load on the manufacturing resources.