Sequencing

Sequencing optimize operation sequence on resource. Simulation plan orders one by one as early as possible and then pull-up if pull-up is activated. The result is a plan which delivers as much as possible on time, but the consequence is the operation sequence is not yet optimized. Sequencing contains seven methods which can optimize operation sequences plans, which can reduce setup time. Sequencing plan some operations earlier to improve operation sequence, but the consequence is that other operation are planned later which can result in delays.

These sequencing types are available for sequencing steps:

- Standard

- Setup time

- Oven

- Cyclic

- Batch-sizing

- Oven repetition

- Multilevel

Sequence optimization controls

The purpose of setting up Sequence Optimization Controls is to define steps to automatically perform sequence optimization of operations during automatic simulation. The purpose of sequence optimization (sequencing) is to reduce operating costs and raise resource utilization by reducing set up times.

The Sequence Optimization Controls component contains information that applies to operations that should be sequence optimized automatically on specific work centers. This component contains several functions for smoothly maintaining your sequence optimization data including the advanced sequencing step type: Cyclic sequence optimization.

Sequence optimization controls are used as a part of the initial step in Automatic Simulation (parameters set by the user controls which steps that are included):

- The initial steps includes:

- Deleting plan

- Planning operations with status locked (20) and in progress (50)

- Keeping operations with status sequence optimized (15) and sequence locked (17)

- Conducting automatic sequence optimization

- Forward planning with respect to finite capacity

- Backward planning based on infinite capacity

Thus, sequence optimization is the last part of the initial planning step. All sequencing steps respect the existing plan as their initial starting point.

- A step group defines a group of steps.

- A step defines all parameters controlling optimization such as grouping control, work center, minimum, and maximum time allowed for grouping, gap control, etc.

- A profile defines the grouping profile. One or more lines can define a profile.

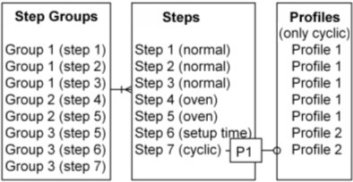

The relationships between these three elements are illustrated in this diagram:

A step group has to be related to at least one step definition. Multiple steps are possible (in the diagram above, Group 1 includes Step 1, 2 and 3, Group 2 includes Step 4 and 5, and Group 3 includes step 5, 6 and 7). If the sequencing step type Cyclic is chosen, a profile for the cyclic optimization has to be defined and connected to the step. Each step can only be related to one profile (in the diagram above, Step 7 is related to Profile 1 (P1) which consists of five records). It is not mandatory to use the step groups, but they can be convenient if you have a very complex sequence optimization task in you factory. If a sequence optimization is simple and only consists of a few steps, the steps can be defined without using step groups.

Each step and step group can be enabled or disabled individually. A step is only included during sequence optimization if both the step group and the step is enabled. (For example, if Step 4 and 5 are enabled, but Group 2 is disabled, then these steps are not included in sequence optimization.)

The order of the steps must reflect the production flow necessary for an optimal and realistic result. When you activate sequencing, each step is executed in the order in which it is defined.

Co-sorting keys are a crucial element in controlling sequence optimization. Parts of the co-sorting key pertain to sequencing and assist the system in selecting operations for sequence optimization. The co-sorting key is defined on each operation and determines the grouping and sorting of operations.