Sequencing - Batch-sizing

Batch size adjustments are conducted in the planning application.

In some food and beverage companies, several end item orders can be created from a same semi-manufactured product, typically as some sort of a mixed product. The batch size of the semi-manufactured product may be fixed because the quantity fits a container of a certain size.

Batch Size Adjustments are based on a few user-defined parameters. The functionality adjusts the size of the order quantities on component orders (Manufacturing Order Proposals or MOP) to best fit the fixed batch sizes. To ensure that the semi-manufactured product is entirely used, the program calculates which end item orders best use the surplus quantity from each batch and distributes the surplus among them.

Using the concept batch size adjustments results in:

- Primary result

- Batch size adjustments optimize the batch size at the lowest network level (component level). Orders are only firmed inside the specified horizon, which means that Batch-sizing is dynamic.

- Batch size rules pertaining to the size of different containers are respected for order quantities on the component level.

- The surplus resulting from combining component orders in batch sizes is distributed in the most optimal way on the parent order level (one level up). This is done by using the advanced logic provided by the planning application.

- Changes in M3 BE

The changed quantity on orders is transferred back to the M3 BE.

Before batch size adjustments can be conducted, these prerequisites must be met:

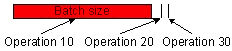

- Batch size adjustments are only relevant for orders on two levels. In the following description, these levels are referred to as component and parent level.

- It is only possible to combine orders at the lowest level in the network (the component level).

- Production quantities at the component level concern larger loads (batches), while production quantities on the parent level concern smaller orders. This means that one component level batch typically delivers to more than one parent order.

- The orders included in batch size adjustments must have very few problems related to external requirements. It can therefore be assumed that all critical external requirements used in the production of the end item are available. Nevertheless, it is always possible to run a Shortage Check after the batch size adjustment.

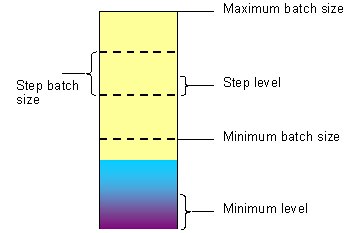

- Batch-sizing rules must be defined per resource (Minimum level, Minimum batch size, Maximum batch size, and Step batch size) or on the sequencing step (controlling all resources).

- Batch size adjustments change the quantities on orders and order links from component to parent orders in the network. We recommend you to copy the plan to another version before running a batch size adjustment simulation because this action can not be undone.

- Batch size adjustments only alter existing orders. No new orders are created. If an order quantity is reduced to zero it is transferred to M3 BE as an order with the quantity zero and deleted in the next MRP run.

- The co-sorting key, used to group similar component orders, must contain the item number.

- Planning method must be set to Lot for Lot on M3 BE.

Purposes of batch size adjustments

The primary purpose of batch size adjustments is to group orders with the same co-sorting key (item number) into a group of orders where the total quantity is as close as possible to a batch size, within a specified time frame. This results in as few corrections to the parent order quantities as possible.

The second purpose is to distribute the surplus. This is done by adjusting the quantity on the parent orders to use the semi-manufactured product completely.

The information needed to handle these tasks is placed on the sequencing step, the work center resource and/or the order.

The adjustment of batch size on the component orders is controlled by the sequence optimization step type: Batch-sizing. The parts of the adjustment are defined in the setup panel for this sequencing step. They are:

- Defining rules for combining component orders in a batch

- Defining parameters for distributing the surplus

The work center given on the sequencing step selects the operations and thereby the orders.

How orders are collected into a batch

Operations with equal grouping part of the co-sorting key are collected into a batch on the component order level. The first operation initiates the sequence optimization. This is the operation applying the earliest start time that is not yet optimized.

The operation grouping process is assigned a maximum time for completion. An operation is associated with one group only if the difference between planned start for the operation and planned end for the earliest (first) operation in the group is not larger than specified by the parameter Maximum time allowed for grouping.

A Look-ahead factor can be used to define a look-ahead horizon. The look-ahead horizon is created by multiplying the look-ahead factor by the Maximum time allowed for grouping. This extended period is used to fill sequence groups (batch sizes) with a quantity lower than the Minimum Level.

If the batch collected within the Maximum time allowed for grouping has a quantity lower than the defined Minimum Level it is increased with additional operations from the look-ahead horizon until it reaches the Minimum Level and a full batch size can be produced. The remaining operations within the look-ahead horizon will not be included in scheduling until the next Batch-sizing process or later.

Batch-sizing method

Batch-sizing can be conducted in two different ways:

- As a fixed Batch-sizing, where the fixed batch size is given by the user.

- As a multiple Batch-sizing, where some rules for setting the batch size are defined by the user.

You can disable Batch-sizing by selecting none. This option is used for example to disable the Batch-sizing on a particular resource in a work center. This option is useful if all the work center resources in the work center except one should be included the Batch-sizing.

When the option fixed batch size is chosen, a batch size quantity defined in the field Minimum batch size is produced when the order quantity on the component orders collected in a group exceeds the Minimum level.

The Minimum batch size is the minimum batch size to be produced. Several Step batch sizes can be added to the Minimum batch size, in cases where the quantity exceeds the defined Step levels, until the batch size reaches the Maximum batch size.A batch is only produced if the order quantity on the component orders collected in a group exceeds the Minimum level.

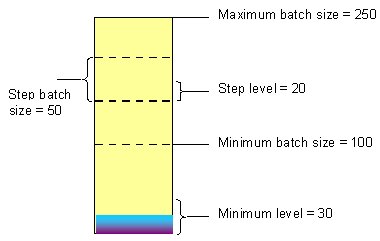

The parameters used to set up multiple batch sizing are illustrated in this diagram:

Examples from a food and beverage factory

In a Food and Beverage factory, which manufactures juice, the work center resource used for blending the juice is a big tank. The following Batch-sizing parameters are valid for this tank:

A batch is only produced if the order quantity on the component orders Minimum level = 30 liters

Minimum batch size = 100 liters

Step level = 20 liters

Step batch size = 50 liters

Maximum batch size = 250 liters

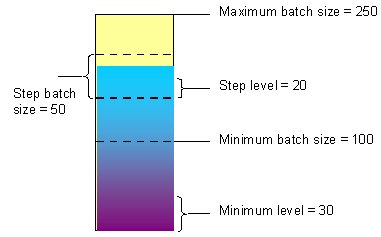

In the process of grouping operations with the same co-sorting key, the group quantity within the Maximum time allowed for grouping horizon is 15 liters (shown on-line in blue). This means that the quantity to be produced is below the Minimum level, which is defined as 30 liters. The look-ahead horizon is activated to check if more operations with the same co-sorting key should be added to the group, for the group quantity to get above the Minimum level. If this is not the case, the operations in the group are scheduled with warning 14 and without any quantity changes. (This warning status can only be seen after the sequencing and before the order scheduling).

In the process of grouping operations with the same co-sorting key, the group quantity, within the Maximum time allowed for grouping horizon, is 180 liters (shown on-line in blue). This means that the group quantity is above the Minimum batch size of 100 liters plus a Step batch size of 50 liters plus the Step level of 20 liters. The group is then increased to the next batch size. In this case, the minimum batch size plus two step batch sizes gives a resulting batch size of 200 liters.

Principle of batch size adjustments

The batch sizing adjustment principle is illustrated by the following example.

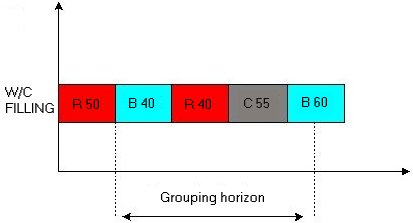

In a two-level production, the co-sorting key of component orders consists of 1 character, which displays the item number. On the work center FILLING, the first scheduled operation is R with the quantity 50. The fixed batch size is set to 100. The grouping process collects operations with the grouping part of the co-sorting key set to R and a quantity as close to 100 as possible.

Within the grouping horizon, the operations R with a quantity of 50 and R with a quantity of 40 are collected into one group. The original order quantity is 90 and the produced batch size is 100. There is a one-to-one relationship between the component orders and the parent orders. This means that a surplus of 10 is to be distributed among the parent orders.

Surplus calculation

The surplus distribution can be defined to treat the surplus as Discrete or Continuous.

- Discrete surplus distribution is used when the parent orders demand for component orders are calculated in whole numbers (integers) and all parent quantity increases are done according to whole numbers of the material requirement. This option is used for production environments, where the production is done in discrete pieces. For example, in a production of canned food, The original quantity on a parent order is 300 cans and the surplus quantity is 40,7 cans. Since it is not possible to produce 340,7 cans, the produced amount must be 340 or 341 cans.

- Continuous surplus distribution is used when the parent orders demand for component orders are calculated in real numbers. This option is used for flow oriented production environments. For example, in a production of a liquid ingredient the quantity after surplus is 540,7 liters of the end product.

Surplus distribution rules and priorities

The surplus can be handled in two different ways depending on the available level of details in the order data:

- Surplus distribution rule. Setting up overall rules for how the surplus is distributed.

- Surplus distribution priorities. Using surplus distribution priorities on orders to find out how the surplus is distributed.

Surplus distribution rules are defined on the sequencing step and cover the orders on all resources in the current work center. The rules can also be defined on each work center resource. (It can also be done in a combination, but the settings on the resource will always overrule the settings on the step).

You can choose from these Surplus distribution rules:

- First order. The surplus is added to the first parent order.

- Last order. The surplus is added to the last parent order.

- Evenly. The surplus is added as evenly as possible between the parent orders. Nevertheless, you cannot always divide the surplus 100% evenly. The example beneath will explain the calculations behind this surplus distribution rule.

We recommend you to use the surplus distribution rule Last order if there is usually scrap in the production of the parent order. If a number of parent items (using the component orders combined in a batch) are scrapped, it always affects the quantity of the last parent order. When placing the surplus on last parent order, it can be used as a buffer to avoid making this order smaller than originally scheduled.

When using the surplus distribution rule Evenly, and the surplus distribution calculation method Discrete, some extra calculations are sometimes necessary to meet the fixed parent order quantities.

The calculations are done in this way:

- The parent orders connected to the adjusted component orders are found.

- The parent orders' total component order requirement is calculated. The value is divided into the batch amount, which gives a factor. Each order quantity is multiplied by this factor and the order quantity result is rounded to the next highest integer value.

- The new order quantity is now multiplied by the quantity per item and a new subtotal is calculated. The rest of the component batch is divided between the parent orders as follows: The orders are sorted in terms of decreasing use of the component (subtotal) and quantity per item. The quantity at the first order is increased as much as possible. Then these orders on the list are also increased as much as possible until the remaining quantity is zero, or there are no more orders:

In this example a batch size of 5000 component items is divided evenly among the parent orders:

In the table below, the first parent order quantity is 50. The parent order uses 20 of the component items for each parent item. This means that the parent order uses 1000 units of the component. The next parent order of 75 uses 750 units of the component and so on. All these contributions added together gives a use of 3500 units. This means that there is a surplus of 1500 components to be distributed evenly. The batch quantity of 5000 is divided by the used quantity of 3500 and the output is a factor of 1,43. The factor is multiplied with the first parent order quantity of 50. This gives a new order quantity of 71. This is multiplied with the quantity per item of 20 and the result is a new increased order quantity of 1420. The next parent order of 75 is multiplied with the factor of 1,43 and multiplied with the quantity per item of 10. This gives a new order quantity of 1070.

When all the increased order quantities are added together it shows that only 4986 component items are used by the parent orders. This means that a remainder of 14 items is still left for the surplus distribution. This is going to be divided among the parent orders according to these rules:

All the parent orders are sorted by demand (subtotal) and quantity per item. This sorting method allows the largest orders first priority. The order of 1000, 20 is the largest according to this sorting method. Each parent item uses 20 of the component, so the remainder of 14 is too small to meet the demand. The next order is 750,10. Each parent order uses 10 of the component, so 10 out of the remaining 14 component items can be distributed to this order. The next order is 750, 0.5. Each parent order uses 0.5 of the component, so the last 4 of the component items are distributed to this order.

If surplus distribution priorities are used, then the priority is defined on each order. This requires much more detailed information about the orders such as information about which orders are produced to stock, or on which orders an extra quantity will cause fewer problems than on others.

The considerations in the priority decision for each parent order could be the following:

- Some parent products may only be produced in the originally ordered quantities.

- On what kind of end-items can extra production be preferred? For example, on stock items, which are frequently sold.

You can choose among these Surplus distribution priorities:

- . The parent order quantities are not increased on those orders. If all orders in the group are set to Not allowed, a warning is issued in the spool-file.

- . The parent order quantities are only increased on first priority orders. If there is more than one first priority order, then the quantity is distributed among them according to the surplus distribution rules.

- . The parent order quantities are only increased on second priority orders if there are no orders with first priority. If there is more than one second priority order, then the quantity is distributed among them according to the surplus distribution rules.

- Choose to use the Surplus Distribution Priorities.

- Defining the priority on each order.

- Define the Surplus Distribution Rule to be used on the priority orders.

The program first selects the orders that have the highest priority. Afterwards, the surplus is distributed among those orders according to the Surplus Distribution Rules.

This table shows the Surplus Distribution Priorities used together with Surplus Distribution Rules:

| Order surplus distribution priority | Result |

|---|---|

| All orders have priority Not allowed | No batch-sizing is done. Spool-file message 5664W is issued. |

| Only one order has First priority. All other orders have something else. | The surplus is added to the first priority order. |

| More than one order has First priority. | The surplus is divided among those orders according to the surplus distribution rule. |

| No orders have First priority but one order has Second priority. | The surplus is added to the second priority order. |

| No orders has First priority but more than one order has Second priority. | The surplus is divided among those orders according to the surplus distribution rule. |

| More than one order has First priority and more than one order has Second priority. | The surplus is only divided among the first priority orders according to the surplus distribution rule. |

Surplus triviality limit

Some important special characteristics of Batch Size Adjustments are mentioned in the following:

All orders (both component and parent orders) included in Batch-sizing are marked. This mark is checked, each time an operation is handled in a sequencing step. If an operation has already been Batch-sized, then the operation is skipped (scheduled with status 10). After the sequencing and before the order scheduling the operation have a warning 14, Batch-sizing Failed. A spool-file message 5661W appears.

The Batch Size Adjusted operations for the components are scheduled right next to each other in the Scheduling Board. The first operation includes the whole batch size. The following operations are symbolized by thin lines. Each of the following operations is scheduled to take 1 second.

The result of the Batch Size Adjustment can be checked in the Work Center Resource Schedule. The Supply/demand report is specially designed for analyzing how batches of component orders are combined and how the surplus is divided among the demanding parent orders.

Recommended workflow

This workflow is recommended, when using the Batch Size Adjustments function:

- Conduct an Automatic Simulation.

- Conduct a second Automatic Simulation in which the option Sequencing is activated. The orders are now Batch Size Adjusted and planned according to the new sizes.

- Check the Batch Size Adjustments in the Work Center Resource Schedule by using the supply/demand report option.

- Firm the MO Proposals. This is done automatically by using Planning Time Fence or manually from the panel Orders-Order View.

- The plan is transferred back to M3 BE, where all decisions in the plan are updated, including the new order sizes.

A spool file logging functionality can be activated. This will provide details as to what happened during the sequence optimization. Because sequence optimization is a part of the Initial Step in Automatic Simulation, the log information will be written in the SCHA spool file.