Raw Material Shipped Quantity and Raw Material Content

These reports are based on the same information and logic, but presented from two different perspectives:

- The Raw Material Content report lists raw material usage. The quantity used per lot and percent content of the raw material in an end product or semifinished product are displayed. If panel setting Attribute Details is set to Included for the report, the report will display a nested grid in connection to the component item.

- The Raw Material Shipped Quantity report lists all shipments that contain the selected raw material, the content and percent content of the raw material lot in the shipped product.

For both reports, the base assumption is that all raw materials can be viewed as mixed in one batch before the production. Therefore, raw materials are evenly spread at the production level where they are applied. Raw materials are assumed to be evenly spread in all the products that are reported on a manufacturing order, co-products, by-products, and end products.

In both reports, all quantities are converted into one common unit of measure. The used unit is provided by the M3REPORT:RMContent_Unit setting. For the report to be correct, this unit must be defined as the base unit, or the alternate unit, for all raw materials, semifinished products, and end products. If this conversion factor is missing, the content is 0. Catch weight is used as quantity where applicable. The catch weight unit must be specified for the M3REPORT:RMContent_Unit setting.

Percent content is calculated according to this formula:

Material content/product content*100

Therefore, the sum of percentage content differs from 100% in these cases:

- Reported usage does not reflect the reported products.

- The receipt is incorrectly balanced.

- The unit conversion factors are incorrect.

You can suppress raw material, such as packaging, from the calculation and output of the report. Material can be suppressed by item type, item group, or product group. To do this, copy or edit one or more of these settings:

- .M3REPORT:RMContent_suppress_Item_type

- .M3REPORT:RMContent_suppress_Item_group

- .M3REPORT:RMContent_suppress_Product_group

To exclude raw material and semifinished material from the output of the report but include them in the calculations, use these settings:

- .M3REPORT:RMContent_omit_Item_type

- .M3REPORT:RMContent_omit_Item_group

- .M3REPORT:RMContent_omit_Product_group

Each setting can hold one or more values. You must use this syntax:

'gr1','gr2','gr3'

If the setting is incorrectly specified, then no result is returned in the report.

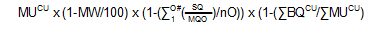

Material content in the product is calculated according to this formula:

This table shows the description of the formula values:

| Value | Description |

|---|---|

| MUCU | Material usage in calculation unit |

| MW | Material waste percentage as specified on the material line |

| SQ | Scrapped quantity for an operation |

| MQO | Manufactured quantity for an operation |

| ∑BQCU | Sum of manufactured quantities that are produced by co-products and by-products at an operation in calculation unit |

| ∑MUCU | Total sum of material usage for all items in calculation unit for all operations up to, and including, the current operation |

| O# | Current operation number |

| nO | Number of operations up to, and including, the current operation |

Raw Material Content / Attribute Details

The attributes of a component item and its connected lots can optionally be included in the Raw Material Content report. When included, the attribute details appear as a nested grid under the component record in the report.

The attribute details can also be included in the export of the Raw Material Content report to Microsoft Excel. You can use the Panel Settings panel to select and configure the included attributes. Note that there is an export limit of ten selected attributes.