Reorder policy

The reorder policy is the method you use to determine the most efficient way to order inventory for your company.

Fixed Order Point

Fixed order point (FOP) is a replenishment method that automatically orders items when the available quantity falls below a set reorder point. With this method, each item is assigned its own reorder point.

For example, if an item is assigned a reorder point of 50, the Inventory Control application automatically places an order for this item when its available quantity falls below 50. The application automatically determines what quantity to reorder based on the reorder quantity code set for the item.

Time-Phased Order Point

Time-phased ordering (TPO) is a replenishment method that calculates the reorder point based on supply and demand.

TPO enables you to analyze fluctuations in demand and then plan future orders based on past ordering trends. For example, you may notice that an item, such as facial tissue, has a seasonal trend. During the flu season, you may need to order more boxes of tissues than you do in non-flu seasons.

You can use TPO to replenish inventory based on projected item availability by periods. TPO normally applies to items with long leadtimes. You can plan orders for up to 52 periods. The application calculates projected item availability as follows:

Projected Item Availability = Stock-on-hand Quantity - (Firm Demand + Remaining Forecasts) + Scheduled Receipts

The application calculates replenishment orders when the projected available quantity falls below the safety stock quantity. The following example shows how the application calculates item availability. For the first period, the projected availability is 61 = (94 - 23 - 60 + 50). Because the safety stock is 40, the application creates an order quantity of 100.

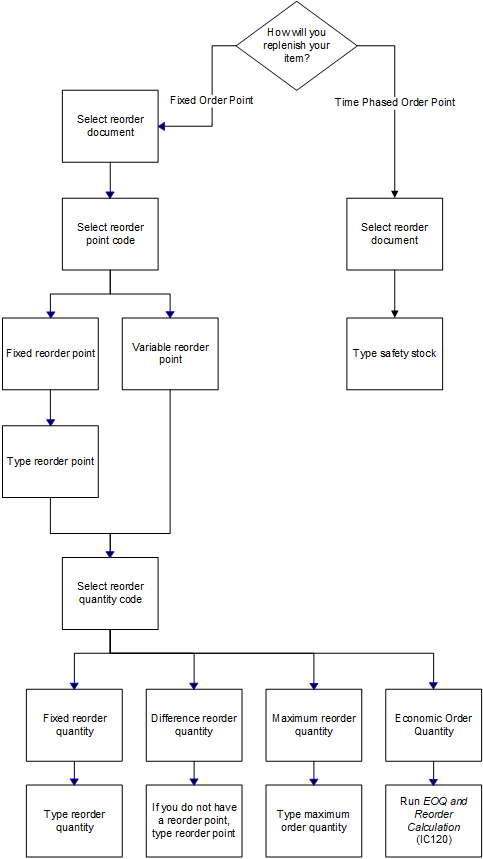

Setting up a Reorder Policy

You begin your reorder policy setup process by deciding whether to use Fixed Order Point (FOP) or Time-phased Order (TPO). When you are ready to set up the reorder policy, refer to the following chart. The chart visually explains the process of defining replenishment information for each item and shows the part that each replenishment concept plays in your setup decisions.