Copy BOM Components to Order (tdpur4812s000)

Use this session to copy a bill of material (BOM) to the lines of a purchase order for a specified quantity of a manufactured item. You must also enter a number of phantom levels to skip.

To start the process, enter:

- The manufactured item.

- The quantity ordered.

- The BOM levels. A purchase order line is added for each position in the BOM which has no underlying components. Only those BOM components are copied for which the order date lies between the effective date and the expiry date of the component in question. The item version is also taken into account.

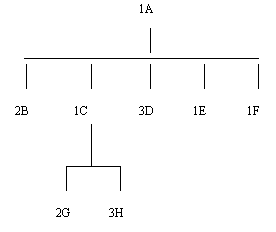

The procedure is illustrated by the following bill of material:

If you copy the BOM for 4 units of item A, 6 purchase order lines are added to the order:

- 1 order line with 8 units of item B.

- 1 order line with 8 units of item G.

- 1 order line with 12 units of item H.

- 1 order line with 12 units of item D.

- 1 order line with 4 units of item E.

- 1 order line with 4 units of item F.

You can still modify order lines after copying. Prices and discount are automatically determined as usual.

Field Information

- Main Item

-

The manufactured item for which the BOM is copied to the purchase order lines.

- Effectivity Unit

-

- Ordered Quantity

- Inventory Unit

- Maximum Number of Phantom Levels to be Skipped

-

This field indicates how many bill of material (BOM) levels are summarized when you use phantoms.

- Project

-

Note: To create a peg distribution for new order lines, specify a value in this field. A peg distribution with one distribution line is generated for the entire ordered quantity in the Purchase Peg Distribution (tdpur5100m000) session.

- Element

-

Note: To create a peg distribution for new order lines, you can specify a value in this field. A peg distribution with one distribution line is generated for the entire ordered quantity in the Purchase Peg Distribution (tdpur5100m000) session.

- Activity

-

Note: To create a peg distribution for new order lines, you can specify a value in this field. A peg distribution with one distribution line is generated for the entire ordered quantity in the Purchase Peg Distribution (tdpur5100m000) session.

- Peg Change Reason

-

The change reason for manually creating the pegged supply. The reason must be specified only if the Manual Project Peg Modification check box is selected in the Project Pegging Parameters (tcpeg0100m000) session.

The project peg changes and the reason codes are logged in the Cost Peg Audit History (tpctm2500m000) session.

- Error Report

-

If this check box is selected, a report is printed with the errors that occur during the copying process.

- Ignore Warehouse from BOM

-

If this check box is selected, a warehouse is defaulted to the order line by using the standard warehouse defaulting logic for manually entering an order line.

Standard warehouse defaulting logic:

- Product variant (only for items with the default supply source set to Assembly in the Items (tcibd0501m000) session).

- Ship-from business partner

- Item purchase data

- Purchase order header

- User profile

- Item ordering data

- Purchase office

If this check box is cleared, the Warehouse from the Bill of Material (tibom1110m000) session is defaulted to the order line.