To create pareto charts

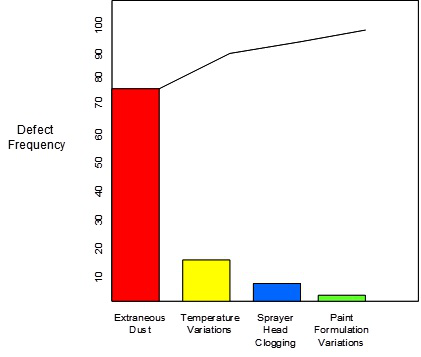

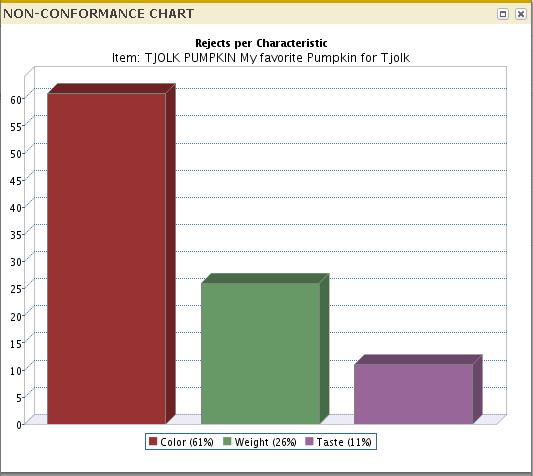

Pareto charts are used to identify the item characteristics that contribute most to non-conformance, and therefore require more improvement.

To plot this chart you must select the combination of item or item/supplier, inspection source, aspect/characteristic and the relevant time period. This chart is based only on actual inspection results.

Example:

The total percentage is not 100 percent. Example 3 Characteristics with all the same number of rejects will be 3 times 33 percent. However, it is not possible to round off one result to 34 percent

Pareto chart data

The data is saved in the Reject Statistics by Characteristic (qmptc1545m000). You can modify/create data based on the following rules:

- Create/Update a record only when there is a recommended reject quantity for the order inspection.

- Create/Update the entire reject quantity. When the result of the inspection order line is rejected for a characteristic, the total order quantity is considered as reject quantity.

The below example explains how data is entered in the Reject Statistics by Characteristic (qmptc1545m000) session.

| Batch | Batch Qty | Rejected Qty | Characteristic | Sample | Sample Good | Sample Bad | Pareto Analysis |

| 1 | 1000 | 1000 | C1 | 10 | 7 | 3 | 75% (3/4) |

| C2 | 10 | 10 | 0 | 0% (0/4) | |||

| C3 | 10 | 9 | 1 | 25% (1/4) | |||

| 2 | 1000 | 0 | C1 | 10 | 10 | 0 | 0% (0/1) |

| C2 | 10 | 8 | 1 | 100% (1/1) | |||

| C3 | 10 | 5 | 0 | 0% (0/1) | |||

| Total | 2000 | 2000 | C1 | 20 | 17 | 3 | 60% (3/5) |

| C2 | 20 | 18 | 1 | 20% (1/5) | |||

| C3 | 20 | 14 | 1 | 20% (1/5) | |||

| 4000 | 60 | 49 | 5 |

- For Batch 1, the results are: C1 - 75%, C3 - 25%, C2 - 0% (batch 1 rejected)

- For Batch 2, the results are: C2 - 100%, C1 - 0%, C3 - 0% (batch 2 accepted)

- For the item (total in the period), the results are: C1 - 60%, C2 - 20%, C3 - 20% (total of both batches).

| Order Inspection | Item | Recommended Accepted Quantity | Recommended Rejected Quantity |

| ORD001 | Item001 | 100 | 0 |

| ORD002 | Item002 | 0 | 100 |

| ORD003 | Item003 | 80 | 20 |

The inspection orders and lines data is:

| Order Inspection | Inspection Order | Line | Aspect/Characteristic | Result |

| ORD001 | INS001 | 10 | Width | Accepted |

| ORD001 | INS002 | 20 | Weight | Accepted |

| ORD002 | INS003 | 10 | Width | Accepted |

| ORD002 | INS004 | 20 | Weight | Rejected |

| ORD003 | INS005 | 10 | Width | Accepted |

| ORD003 | INS006 | 20 | Weight | Rejected |

The following reject statistics is generated:

| Item | Aspect/Characteristic | Rejected Cumulative |

| Item002 | Weight | 100 |

| Item003 | Weight | 20 |