Example of Handling Unit building during picking using Prepacking Advice

1

The warehousing order type has Sequencing implemented and the Sorting method used during picking is Ascending. The package definition used in this example is PKDF01.

| Parent Node | Node | Packaging Item | Virtual | Packaging Item Quantity | Quantity | Allow Multi Item for Shipping | Single Reference | Single Reference A | Single Reference B |

|---|---|---|---|---|---|---|---|---|---|

| 0 | 1 | Pallet | No | 1 | 0 pcs | Yes | No | No | No |

| 1 | 2 | Box | No | 3 | 0 pcs | Yes | Yes | Yes | No |

| 2 | 3 | Yes | 0 | 180 pcs | No | Yes | Yes | Yes |

This handling unit template has in total 180 pcs, divided over 3 boxes, maximum of 60 pcs per box.

| Order | Item | Package Definition | Quantity |

|---|---|---|---|

| Sales Schedule S1 / 10 | ITEM001 | PKDF01 | 20 pcs |

| Sales Schedule S1 / 20 | ITEM002 | PKDF01 | 20 pcs |

| Sales Schedule S1 / 30 | ITEM003 | PKDF01 | 20 pcs |

| Sales Schedule S1 / 40 | ITEM001 | PKDF01 | 80 pcs |

| Sales Schedule S1 / 50 | ITEM002 | PKDF01 | 40 pcs |

| Order Line Ref. Distr. | Item | Reference | Quantity |

|---|---|---|---|

| Sales Schedule S1 / 10-1 | ITEM001 | 202 | 20 pcs |

| Sales Schedule S1 / 20-1 | ITEM002 | 203 | 20 pcs |

| Sales Schedule S1 / 30-1 | ITEM003 | 201 | 20 pcs |

| Sales Schedule S1 / 40-1 | ITEM001 | 204 | 80 pcs |

| Sales Schedule S1 / 50-1 | ITEM002 | 205 | 40 pcs |

A projected shipment with 5 lines is created; LOAD00001 with shipment SHIP00001.

| Advice | Order | Item | Package Definition | Quantity | Load | Shipment | Shipment Line | Distribution Line |

|---|---|---|---|---|---|---|---|---|

| 1 | Sales Schedule S1 / 10-1 | ITEM001 | PKDF01 | 20 pcs | LOAD00001 | SHIP00001 | 10 | 1 |

| 2 | Sales Schedule S1 / 20-1 | ITEM002 | PKDF01 | 20 pcs | LOAD00001 | SHIP00001 | 20 | 1 |

| 3 | Sales Schedule S1 / 30-1 | ITEM003 | PKDF01 | 20 pcs | LOAD00001 | SHIP00001 | 30 | 1 |

| 4 | Sales Schedule S1 / 40-1 | ITEM001 | PKDF01 | 80 pcs | LOAD00001 | SHIP00001 | 40 | 1 |

| 5 | Sales Schedule S1 / 50-1 | ITEM002 | PKDF01 | 40 pcs | LOAD00001 | SHIP00001 | 50 | 1 |

| Advice | Order | Item | Package Definition | Quantity | Load | Shipment | Shipment Line | Distribution Line |

|---|---|---|---|---|---|---|---|---|

| 3 | Sales Schedule S1 / 30-1 | ITEM003 | PKDF01 | 20 pcs | LOAD00001 | SHIP00001 | 30 | 1 |

| 1 | Sales Schedule S1 / 10-1 | ITEM001 | PKDF01 | 20 pcs | LOAD00001 | SHIP00001 | 10 | 1 |

| 2 | Sales Schedule S1 / 20-1 | ITEM002 | PKDF01 | 20 pcs | LOAD00001 | SHIP00001 | 20 | 1 |

| 4 | Sales Schedule S1 / 40-1 | ITEM001 | PKDF01 | 80 pcs | LOAD00001 | SHIP00001 | 40 | |

| 5 | Sales Schedule S1 / 50-1 | ITEM002 | PKDF01 | 40 pcs | LOAD00001 | SHIP00001 | 50 | 1 |

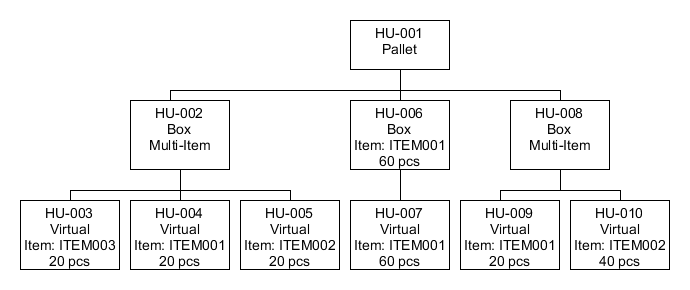

After the complete picking process has been executed, this handling unit structure is linked to shipment SHIP00001.

2

The same scenario as in Example 1 is considered. Starting point is the same, sequencing is implemented, and sorting method is Ascending. The only difference is Packing Advice is added to the process.

| Order | Item | Package Definition | Quantity |

|---|---|---|---|

| Sales Schedule S1 / 10 | ITEM001 | PKDF01 | 20 pcs |

| Sales Schedule S1 / 20 | ITEM002 | PKDF01 | 20 pcs |

| Sales Schedule S1 / 30 | ITEM003 | PKDF01 | 20 pcs |

| Sales Schedule S1 / 40 | ITEM001 | PKDF01 | 80 pcs |

| Sales Schedule S1 / 50 | ITEM002 | PKDF01 | 40 pcs |

| Order Line Ref. Distr. | Item | Reference | Quantity |

|---|---|---|---|

| Sales Schedule S1 / 10-1 | ITEM001 | 202 | 20 pcs |

| Sales Schedule S1 / 20-1 | ITEM002 | 203 | 20 pcs |

| Sales Schedule S1 / 30-1 | ITEM003 | 201 | 20 pcs |

| Sales Schedule S1 / 40-1 | ITEM001 | 204 | 80 pcs |

| Sales Schedule S1 / 50-1 | ITEM002 | 205 | 40 pcs |

| Shipment Line | Order Line Ref. Distr. | Item | Quantity |

|---|---|---|---|

| SHIP00001 / 10 | Sales Schedule S1 / 10-1 | ITEM001 | 20 pcs |

| SHIP00001 / 20 | Sales Schedule S1 / 20-1 | ITEM002 | 20 pcs |

| SHIP00001 / 30 | Sales Schedule S1 / 30-1 | ITEM003 | 20 pcs |

| SHIP00001 / 40 | Sales Schedule S1 / 40-1 | ITEM001 | 80 pcs |

| SHIP00001 / 50 | Sales Schedule S1 / 50-1 | ITEM002 | 40 pcs |

| Shipment Line | Item | Reference | Quantity |

|---|---|---|---|

| SHIP00001 / 10 | ITEM001 | 202 | 20 pcs |

| SHIP00001 / 20 | ITEM002 | 203 | 20 pcs |

| SHIP00001 / 30 | ITEM003 | 201 | 20 pcs |

| SHIP00001 / 40 | ITEM001 | 204 | 80 pcs |

| SHIP00001 / 50 | ITEM002 | 205 | 40 pcs |

The user can start the prepacking advice session from the shipment header wherein the demands that exist for the projected shipment are displayed. The demands are based on the shipment line reference distribution and are sorted based on the value the “Sequencing during Picking” field is set to.

| Shipment Line | Item | Reference | Quantity |

|---|---|---|---|

| SHIP00001 / 30 | ITEM003 | 201 | 20 pcs |

| SHIP00001 / 10 | ITEM001 | 202 | 20 pcs |

| SHIP00001 / 20 | ITEM002 | 203 | 20 pcs |

| SHIP00001 / 40 | ITEM001 | 204 | 80 pcs |

| SHIP00001 / 50 | ITEM002 | 205 | 40 pcs |

From the advice, a handling unit structure can be generated, based on the demands, the package definition and the handling unit template that is applicable. The handling units can be filled up with inventory from stock. These handling units have the status Projected and are not packed until the actual packing is performed. The status changes to Committed after these handling units are packed and the prepacking advice is completed. These handling units are linked to the prepacking advice line.

The next step in the process is to create the proposed stock points. For each of these demands, the proposed stock points are generated, and this inventory is used to repack for the specific shipment demand.

| Warehouse | Location | Item | Quantity Available |

|---|---|---|---|

| WHAMS1 | BULK001 | ITEM001 | 80 pcs |

| WHAMS1 | BULK002 | ITEM002 | 20 pcs |

| WHAMS1 | BULK002 | ITEM003 | 40 pcs |

| WHAMS1 | BULK003 | ITEM001 | 20 pcs |

| WHAMS1 | BULK003 | ITEM002 | 30 pcs |

| Shipment Line | Item | Warehouse | Location | Quantity |

|---|---|---|---|---|

| SHIP00001 / 30 | ITEM003 | WHAMS1 | BULK002 | 20 pcs |

| SHIP00001 / 10 | ITEM001 | WHAMS1 | BULK001 | 20 pcs |

| SHIP00001 / 20 | ITEM002 | WHAMS1 | BULK002 | 20 pcs |

| SHIP00001 / 40 | ITEM001 | WHAMS1 | BULK001 | 60 pcs |

| SHIP00001 / 40 | ITEM001 | WHAMS1 | BULK003 | 20 pcs |

| SHIP00001 / 50 | ITEM002 | WHAMS1 | BULK003 | 30 pcs |

In this specific example, repacking is most likely done at a predefined location, from which the current stock point inventory must be moved to. The shipment planner may make some changes to the proposed stock points, because demand for ITEM001 is in total 100 pcs. For reference 202, 20 pcs are requested and for reference 204 80 pcs are requested, the stock point for item ITEM001 on location BULK001 is 80 pcs, which is more efficient to use for reference 204. Therefore, The proposed stock points show only the available inventory and not the planned receipts for the specific items that have a shortage.

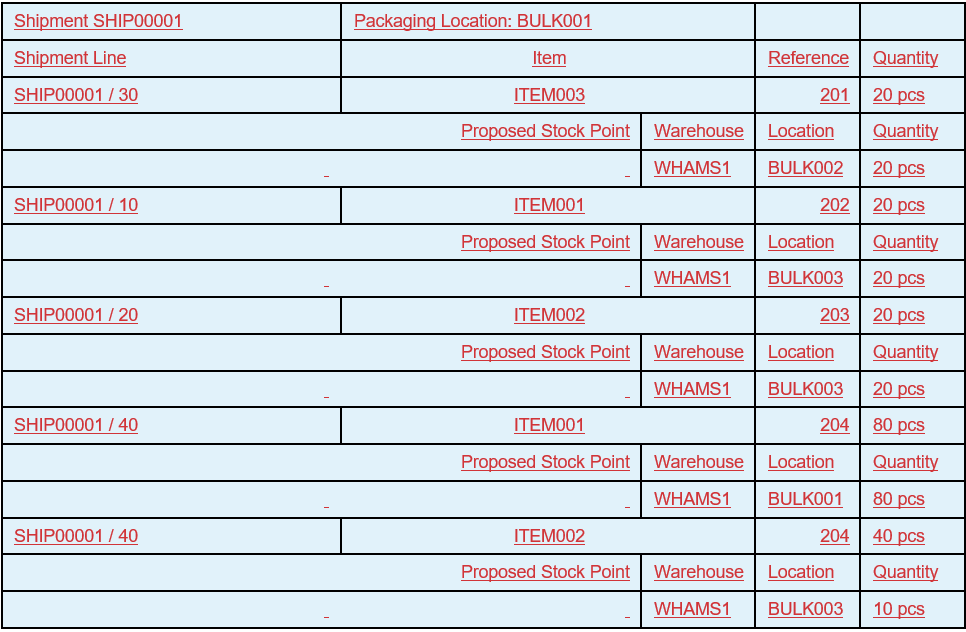

The shipment planner must decide if the prepacking advice is accepted and approve the advice. After the approval, the prepacking advice is printed to be used for actual repacking.

In this example, the shipment planner has made these proposed stock points, and has approved the prepacking advice:

| Shipment Line | Item | Warehouse | Location | Quantity |

|---|---|---|---|---|

| SHIP00001 / 30 | ITEM003 | WHAMS1 | BULK002 | 20 pcs |

| SHIP00001 / 10 | ITEM001 | WHAMS1 | BULK003 | 20 pcs |

| SHIP00001 / 20 | ITEM002 | WHAMS1 | BULK003 | 20 pcs |

| SHIP00001 / 40 | ITEM001 | WHAMS1 | BULK001 | 80 pcs |

| SHIP00001 / 50 | ITEM002 | WHAMS1 | BULK003 | 10 pcs |

| SHIP00001 / 50 | ITEM002 | WHAMS1 | BULK002 | 20 pcs |

The packer has this prepacking advice as a print-out:

The packer can perform the repacking in inventory using this printed advice.

The packer must first move the inventory from the proposed stock points to the prepacking location by moving the proposed stock points to the actual stock points. As part of this process, the inventory is moved to the prepacking advice location. When moved, the inventory is committed against the stock point, and the inventory levels are populated with the committed quantity. In case, lot or serial in inventory is used, the Committed Inventory is updated at that level to prevent the stock points from being used by other processes.

The packing process can be performed as soon as the inventory is available in the prepacking location. The Compose Packaging session can be used for this process. This session displays the packaging advice lines, the actual stock points and the handling unit structure that is linked to the shipment. The packer also has the option to drag/drop the actual stock points to the handling unit structure for performing the actual packing of the handling units.

The packer can now set the prepacking advice to Complete. This sets the packed handling units to Committed. Consequently, the stock point committed quantities are lowered or increased based on the handling unit, as the handling unit commitment is also stock point specific.