Register Quantities and Complete Operation

The workbench allows you to register quantities or complete operation using the buttons in the menu. You must select a production order operation line to enable the Register Quantities and Complete Operation button.

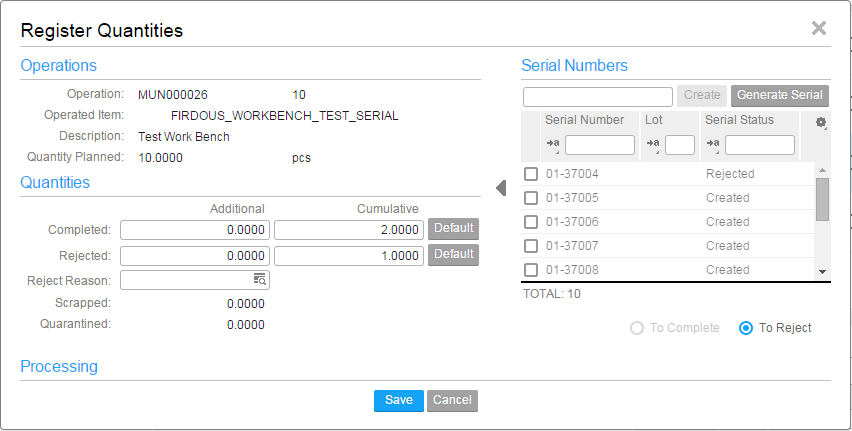

You must select the production order operation line and click the Register Quantities or Complete Operation button to access the Register Quantities section or Complete Operation section. This section allows you to modify the registered or the completed quantity. You can select the 'To reject' or 'To complete' options on the right.

- It is possible to either complete or reject serial numbers. It is not possible to complete and reject serial numbers simultaneously.

- The operator can view the scrapped/quarantined quantity in LN.

-

Registering quantities

The Register Quantities button allows the operator to register completed quantities and rejected quantities for the selected operation.

Quantities can be registered as:

- Additionally Completed

- Additionally Rejected

- Cumulatively Completed

- Cumulatively Rejected

The values in these fields are defaulted from LN when you click Default button. The process is the same as in the Report Operations Completed (tisfc0130m000) session.

It is possible to specify a reason in the Reject Reason field. The reason can be selected from the Reasons (tcmcs0105m000) session.

- It is not possible to specify a reject reason when the Use Reason Codes for Rejected Items is set to Never in the Production Order Parameters (tisfc0100s000) session.

- The rejected quantities must be handled outside the workbench (either to scrap or to send them to quarantine).

-

Completing an operation

Select an operation and click the Complete operation button. The process of recording the quantity is similar to the Registering process. The status of the operation is set to Completed.

- Completing the operation stops the time recording for all operators.

- When operations are reported complete, hours and materials are backflushed, when applicable. This is similar as the logic of the Report Operations Completed (tisfc0130m000) session.

- The materials/hours are only backflushed when the Backflushing Method field is set to Automatic. The value Interactive is not supported by the workbench.

- Backflushing must be executed using the Backflush Materials and Hours (tisfc0220m000) session when the parameter is set to Interactive or Manual.

For more information refer to Actual costing and backflushing.

Serialized Item

It is possible to report serialized items as complete or reject. The serial numbers of the items to be completed or rejected can be selected from a list. You can also generate a serial number based on the mask or specify an arbitrary serial number. When completing or rejecting serialized items, a list of serial numbers is displayed in the Quantity Registration section or the Complete Operation section.

- The list of serial numbers is displayed on the last

operation, by default. You can select the serials that are to be reported as

complete. For other operations, the user can display the serial numbers by

clicking the

icon

located to the right of the Quantity Registration section or Complete Operation

section.

icon

located to the right of the Quantity Registration section or Complete Operation

section. - In case a manufactured end item is serialized or serialized and lot controlled, shop operators can report complete or reject based on the serial number assigned.

- Lot controlled items (no serials), unit effectivity or combination of serials (and lots) with unit effectivity are not supported with the workbench.

The steps to complete or reject the serialized items:

- Enter a quantity

- When the user enters a quantity for the last operation of a production order, or rejects a quantity, a matching serial numbers is displayed.

- The serial numbers with the status set Created, Assigned or Rejected only are displayed.

- Serial numbers with status Created is selected when a positive additional completed quantity or a positive additional rejected quantity is entered.

- Serial numbers with status Assigned is selected when a negative additional completed quantity is specified (reversing a completion).

- Serial numbers with status Rejected is selected when a negative additional rejected quantity is specified (reversing a rejection).

- A message is displayed when there are not enough serial numbers to select to match the entered quantity.

- Select specific serial numbers

- The user can also select specific serial numbers from the list. After selecting one or more serial numbers the user must click the ‘To complete’ or the ‘To reject’ option to indicate action to be performed for the serialized items. The related quantity is populated. The serial numbers with the status set to Created, Assigned or Rejected only, are displayed.

- A positive additional completed quantity is specified when serial numbers with status Created are selected and the ‘To complete’ option is selected.

- A positive additional rejected quantity is specified when serial numbers with status Created are selected and the ‘To reject’ option is selected.

- A negative additional completed quantity is specified when serial numbers with status Assigned are selected (reversing a completion).

- A negative additional rejected quantity is specified when serial numbers with status Rejected are selected (reversing a rejection).

- The serial numbers are actually completed or rejected when selecting the Save button or Complete Operation button.

Generating Serials

The serial numbers can already be available in the workbench, because the number are generated earlier (during document printing, order release, or manually). Else, the serial number must be generated or created in the workbench. Generation or creation of serials is done on a one-by-one basis. The user can create new serial numbers in the following ways:

- Manually enter a new serial number : The user can enter an arbitrary serial number and click the Create button. An error message is displayed if the serial number already exists for the production order, or if the serial number is not available anymore for the production order.

- The user can click the Generate button and a new serial number is generated based on the default mask for the item. The newly generated serial number is displayed at the end of the serial number list.

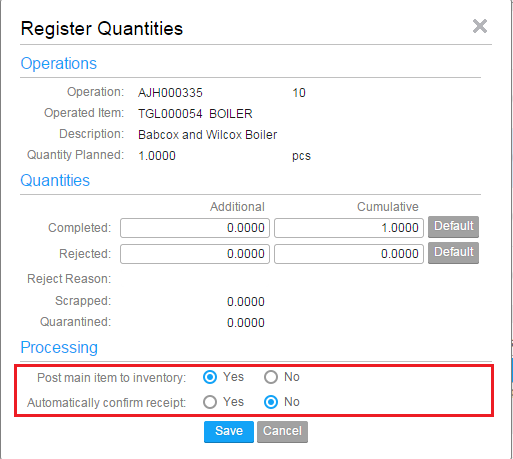

Post End Item to Inventory

The Post to Inventory when Reporting on Last Operation field in the Production Order Parameters (tisfc0100s000) session, determines if a main/end item is posted to inventory.

The functionality of each option and the impact on the workbench is:

- If set to Yes: When

reporting a quantity complete for the last operation and when posting the main

item(s) to inventory, is allowed, the following field is displayed in the

Quantity Registration pane or in the Complete Operation pane:

- Automatically confirm receipt: Select Yes or No to save the completed quantity. The main item is posted to inventory. If the user selected Yes the main item(s) are also received in the warehouse. This field is defaulted based on the Warehouse Receipt activity of the related production warehouse order inbound line. If the receipt activity process is automated, the field “Automatically confirm receipt” is set to Yes; else No.

- If set to No: The main item is not be posted to inventory when a quantity is reported complete.

- Interactive : When reporting a quantity complete for the last

operation and when posting the main/end item to inventory, is allowed, the

following fields are displayed in the Quantity Registration pane or in the

Complete Operation pane:

- Post main item to inventory : Select Yes or No. If the user selects No, it is possible to save the quantity completed and the main item(s) are not posted to inventory. If the user selects Yes, the Automatically confirm receipt field is displayed.

- Automatically confirm receipt : Select Yes or No to save the completed quantity. The main item(s) are posted to inventory. If the user selected Yes ’ the main item(s) are also received in the warehouse.