Glossary

activity manager

A person responsible for planning or carrying out a project activity.

actual completion date

The date on which the items of a production order are (partially) completed or rejected for each operation in the Job Shop Control (JSC) module. The user can overwrite the date.

actual input

The total input quantity of a work center/machine for operations that are Ready to Start during the target period.

actual output

The total output quantity that is reported complete, for operations at a work center/machine during the target period.

actual queue

The actual input minus the actual output of a work center/machine. Note that the queue includes active operations as well as operations waiting to be carried out.

added costs

The increase in value of an item when the item passes through a stage in the production process. Added costs are posted to detailed cost components whereas non-added costs are posted to aggregated cost components.

- For purchased items, added costs are costs of materials plus surcharges.

- For items transferred between warehouses, added costs are the warehouse surcharges.

- For manufactured items, added costs are operation costs plus surcharges.

aggregate

To total figures or amalgamate amounts; to merge items in a higher plan level. Opposite of explode, disaggregate.

collect cost component

A cost component that contains collected costs.

Each item has cost components which have been added together for the following costs:

- Materials costs (contains raw materials costs)

- Operations costs (contains operations costs and subcontracting costs)

- Surcharges (contains item surcharges and warehouse surcharges)

In inventory, value of goods is calculated and posted by the three collect cost components.

aggregation relationships

A specification, expressed as a percentage, how items are aggregated or disaggregated.

To aggregate items means that different items are grouped to form product families for planning purposes. This is also called a planning bill of material. To disaggregate items means that a product family is split up into smaller families, or into items.

Aggregation relationships can have the same structure as a single-level bill of material. However, similar to production bills of materials, also multilevel structures can be created.

Example

allocation

An item quantity that is assigned to a specific order but that is not yet released from the warehouse to production.

alternative material

A substitute for a BOM material that the system can select in case the standard material is out of stock.

An alternative material is supposed to meet the same specifications, but only in the context of a BOM for a specific main item.

alternative tool type

A substitute for a tool type that is not available for use, for example, when a tool is being refurbished.

anonymous item

An item that is produced or purchased before a customer order is received.

If an anonymous item is a manufactured item, it is produced in a make-to-stock production environment. If an anonymous item is a generic item, a product variant is configured without using a PCS project.

answer

The response in a question-and-answer type of user/system interaction (in the Product Classification (GRT) module).

The response can be of three types:

Numeric

For example, 5Alphanumeric

For example, REDAnswer & Follow-up

Based on an answer a new question is raised.

answer group

A set of predefined answers from which an user can select an value in the classification process.

antedating

To enter a date in the past when recording the issue of materials or deliveries of end products into inventory.

This is useful if the user is updating the system some time after the actual manufacturing process took place.

aspect

An aspect is a specification of a feature.

assembly assignment

The set of resources assigned to an assembly line for a particular period of the day. The resources are divided over the line stations to create a balanced line.

Assignments are defined for an assembly line. For each assignment, you specify the cycle time and its activity ranges, which are the period and time ranges for which the assignment is effective. The process characteristics that you define for an assignment include:

- Labor FTE

- Number of Machines

- Work team

- Operations

These process characteristics are linked to other assignments that are, in turn, linked to the assembly assignment. When an assignment is in effect, the assignments that are linked to it are also in effect.

assignment types

Two types of assignments exist, both of which exist at the same time. The average assignment is used for more general purposes, whereas the nonaverage assignment has a very specific period and time range.

Average assignments

Use an average cycle time that is based on the cycle times of the nonaverage assignments for the day. The average assignment is used in planning. Planning is based on cycle time, calendar, and availability type.Nonaverage assignments

Use time-based cycle times that are based on the operations performed on the line. The cycle time can vary according to the time range that is provided for the assignment.

Nonaverage assignments are used to define order content. For generated (nonfrozen) orders, the order content is based on the first active, nonaverage assignment. For frozen orders, the order content is based on the nonaverage assignment that is in effect at the time that the order is frozen.

Nonaverage assignments are also used to offset the lead time during sequencing. When the order is sequenced, a lead time is calculated for every order. This lead time is based on the cycle times, and the applicable cycle time is retrieved from the nonaverage assignment.

assembly line

A set of consecutive line stations in which FAS (Final Assembly Schedule) items are manufactured. The items are manufactured by passing the items from line station to line station and by carrying out operations at each line station. An assembly line is subdivided into a number of line segments separated by buffers. An assembly line can be either a main line or a supplying line.

assembly part

A component used on an assembly line.

An assembly part forms the link between Configurator and Enterprise Planning. Configurator generates the requirements for assembly parts and Enterprise Planning plans the production or purchase of the item.

assembly routing sheet

An order document that lists the assembly operations for the production of FAS items, arranged by line segment.

assembly-material issue note

An order document used to report the estimated, allocated, and issued quantities of required materials for the production of FAS items, arranged by line segment.

available capacity

The total capacity available, for either a day or a week, usually based on the work center calendar.

average setup time

The time required for setting up or changing over a machine before you start running the machine. Setup time can be long, for example, if you change over from using black paint to using white paint. Setup time can be short, for example, if you change over from using white paint to using yellow paint. The setup time must indicate an average of all possible setup times.

backflushing

The automatic issue of materials from inventory, or accounting for the hours spent manufacturing an item, based on theoretical usage and the quantity of the item reported as complete.

backlog

All the customer's orders that are received but not yet shipped. Sometimes they are referred to as open orders on the order board. In assembly line production, orders which are behind schedule.

base unit

If quantities expressed in alternative units are used in calculations or formulas, these quantities are first converted to the base unit.

For each company, base units must be defined for weight, length, surface area, volume, and time.

basic capacity

The normal daily number of operation hours of the resource units of a work center (resource). A resource unit can be a machine or an employee.

The capacity on a work center is Week Capacity [Hours] * Available Labor Resources or Number of Machines. The basic week capacity, the number of operators, and the number of machines are defined in the Work Centers (tirou0101m000) session.

bill of critical capacities

Bills of critical capacities (BCC) indicate the work centers that are regarded as critical in the Master Planning processes. Critical capacities are usually the bottlenecks in a routing.

Enterprise Planning uses the bill of critical capacities to generate the rough capacity requirements for critical capacities.

bill of critical materials

A bill of critical materials (BCM) indicates the components which are regarded as critical during the production process of a plan item.

A bill of critical materials is a kind of summary of the BOM, which contains only the more important components.

Typical examples of critical materials are:

- Components with long lead times

- Subassemblies with a high capacity load for the internal or external production system

The Enterprise Planning package uses the bill of critical materials to generate the critical material requirements for critical materials.

BCM

bill of material (BOM)

A list of all parts, raw materials, and subassemblies that go into a manufactured item and show the quantity of each of the parts required to make the item. The BOM shows the single-level product structure of a manufactured item.

blocking reason

The reason an operation is temporarily not allowed to proceed.

Reasons for blocking are:

- The quality must be inspected.

- The equipment has failed.

- The customer did not pay the last installment.

BOM level

When a product is manufactured, components are assembled into subassemblies, and those subassemblies are in turn assembled into the final product. The components that go together at each stage are described in a bill of material. Each stage is one level in the bill of material.

The listing of the wheel components is one level in the bill of material. The listing of the subassemblies of the bicycle is the highest level, and is frequently referred to as level zero.

Example

A bicycle has one frame and two wheels. The frame is made of three tubes. The wheels are each made of one rim, one hub, and 35 spokes.

BOM quantity

The number of manufactured products to which a bill of materials (BOM) applies. The BOM quantity enables you to specify very small product quantities as BOM components.

Example

You need very small amounts of certain colors to mix one liter of a specific paint, Cotton White. Therefore, a BOM quantity of 1000 liter is defined. The component quantities for the paint can then be as follows:

| Paint Cotton White, 1000 liter: | |

| White | 999 liter |

| Yellow | 0.6 liter |

| Red | 0.2 liter |

| Blue | 0.2 liter |

BOM unit

BOM sequence number

The BOM sequence number allows you to define more than one component item for each position. These interchangeable components can have different dates when they are valid.

LN also uses sequence numbers when you replace items in BOMs.

Example

Say, you make bicycles and use frames that you buy from supplier A until August. However, after August you will use identical frames that you buy from supplier B. Do not use a new BOM position number for the second frame. Instead, use a new sequence number.

bottleneck work center

A work center that determines or limits the production rate of an RPT item when scheduling orders. The work center calendar determines the maximum number of hours per day for planning orders of repetitive items.

bucket

A quantity of time used for planning and backflushing.

budget

A cost estimate in the preproduction stage of projects. Includes an estimate of future costs and revenues related to expected activities.

A budget is linked to a calculation group. Budgets within the same calculation group can therefore be used for simulation purposes.

buffer

An assembly line workstation where no operations are carried out, and where orders are waiting to enter the following work station.

You can use buffers to change the sequence of products from one line segment to another. Buffers in LN are random access type.

buffer (FIFO)

The orders that came in first go out first. As a result this buffer is just a 'pipeline' which can have a certain capacity. No planned sequence change can take place so no line rules can be linked to FIFO buffers.

buffer (random access)

Buffers with random access places. During the sequence process, LN checks these access places to achieve a proper sequence on the next line segment. Line rules can be linked to random access buffers. Line rules sequence the assembly orders which enter the random access buffer.

calculation GRT

Calculations are used in GRT to answer questions in a numeric way. The questions are linked to feature aspects. For example, the surface of a seat can be calculated by answering two questions: width and length. When the two answers are multiplied, the result is a return code for the classification.

calculation group

A code representing a group of projects the user uses to compare financial data.

You can assign a calculation group to:

- A budget

- A main project (as long as the calculation group is not assigned to another project or single project)

- A single project (as long as the calculation group is not assigned to another main project or single project)

calculation office

A work center of the type Costing that is used to determine the enterprise unit for a project, or production order and also has an administrative function.

calculation office variance

The variance in financial production results that is not accounted for by the price variance and the efficiency variance.

A calculation office variance can be caused by an alteration of an end item's standard cost, or by differences between the estimated and the actual surcharges.

The calculation office variance is used to empty the WIP so that all costs are accounted for.

calibration interval

The interval between one calibration and the next. The interval shows when the next calibration will take place: after n days, or after n times used.

capacity unit

The unit in which the capacity of an inventory location is registered. It usually applies to the physical quantity area, volume, or weight and can be converted into the inventory unit.

checklist

An order document to check whether everything is present for the release of a production order. It lists the required materials, tools, machines, and so on.

classification

A process to group items according to predefined features. This also results in a coding system by which item codes can be generated. The reason for doing this is to easily retrieve items, matching certain features.

clustered line station order

Represents all the material requirements for a line station for a day. A CLSO consists of user-defined buckets. The material requirements are combined for each bucket.

In Assembly Control, transactions can be carried out per line station and per period, instead of per order. LN can combine the same materials for a specific period into one material line. After doing so, the cumulated quantity is stored in the CLSO. This accumulation reduces the number of transactions that are necessary, because the transactions are performed for a specific bucket.

CLSO

collective cutting list

A list to cut materials for multiple production orders that are made from the same material. A cutting list is sorted by material code and item group. Using a cutting list can save time.

collective sawing list

A list to saw materials for multiple production orders that are made from the same material. A sawing list is sorted by material code and item group. Using a sawing list can save time.

compile

To translate all the source code of a program from high-level language into object code prior to execution of the program. Object code is an executable machine code or a variation of machine code.

completion date

The date on which the work on a project or order is finished.

- The completion date of a production order is the date on which the order receives the status Completed.

- The completion date of a project is the date on which the project receives the status Finished.

You can still perform certain financial transactions on the order, after it is completed, until you close it. The same is true for projects.

constraint

A set of decision rules (constraints) that control the translation of the customer requirements into the product structure of the variant. These constraints indicate which components and operations will be used in a specific product variant.

constraint

In LN, a means to check, restrict, or compel to avoid or perform some action.

In the Product Configuration module, a constraint is every possible decision rule or calculation conceivable that can be carried out during the definition of the product variants. You can use constraints in the product model for product features, generic BOMs, routings, price lists, and item data. You can use a constraint editor to define constraints.

Among other things, constraints allow you to indicate under which conditions certain combinations of options are acceptable, mandatory, or not acceptable for product features. You can also indicate which bill of material components and/or operations must be included or excluded, what the purchase or sales price structure for a product variant is, and so on.

In the Product Classification module, a constraint consists of one or more constraint lines that define the conditions under which certain return values or calculation results are included in the classification code during item classification.

constraint

In the Product Classification module, a constraint consists of one or more constraint lines that define the conditions under which certain return values or calculation results are included in the classification code during the classification of items.

For example:

- If the chair is red, include r in the classification code.

- If the chair is blue, include b in the classification code.

constraint identification code

The code that uniquely identifies a constraint of a generic item.

constraint validation message

Error messages during the configuration process that can be used in constraints (constraint rules). During the configuration process, LN checks if the selected feature or option comply with the conditions defined by the constraints.

If the selection does not meet these conditions, LN will issue one of the messages recorded in this session to indicate which options are allowed.

constraint validation message

System messages showing the constraint rules during configuration. These rules are part of constraint texts, in the form of either codes or text. Constraint validation messages only refer to constraint sections of type Validation.

container

A vessel used to store or move material.

cost item

An item which is not kept in stock but to which costs are allocated. Example, water, electricity.

standard cost surcharge

The amount charged in addition to the usual cost incurred when manufacturing or purchasing a single item.

costing work center

A work center, linked to a planning work center, that is used to calculate the end item unit costs, WIP transfers, and production results used to hold the financial transactions related to production orders.

The link between a costing work center, and a planning work center enables you to replan production order operations again. If required, you can change the work center that is used to carry out an operation without modifying the costing process.

count point

An operation in a routing, or work station, where the quantity of completed and rejected items must be determined explicitly. If an operation is a count point, completion of that operation must be reported separately. The quantity completed in follow-up operations must not exceed the quantity completed in the count point.

If an operation, or work station is not a count point, it can be set to Completed automatically upon completion of a follow-up operation. The quantities completed and rejected are then determined by the completed quantity in the count point.

covering note

The order document that accompanies a product during the manufacturing process, and that is used for identification purposes.

critical BOM level

The lowest level at which the relevant plan item appears in the bill of critical materials.

critical work center

A work center that is defined by the user as a bottleneck.

current operation

The operation currently carried out with the earliest start date. If more than one operation meets this criterion, the operation with the lowest operation number is the current operation. There can be only one current operation at any one time.

customized item

An item produced on a customer specification for a specific project. A customized item can have a customized BOM and/or a customized routing and is normally not available as a standard item. A customized item can, however, be derived from a standard item or a generic item.

cutting list

An order document that lists the materials to be cut from a larger piece of material, for example, a sheet of metal.

cycle time

The (average) time between completion of two separate units of production. For example, the cycle time of motors assembled at a rate of 120 per hour is 30 seconds.

delivery date

The date the finished items are finished according to the planning.

demonstrated load factor

Combined efficiency and utilization. The ratio of actual output to available capacity, for an operation performed at a given work center or machine.

depreciation code

The depreciation system according to which depreciation, value reduction, revaluation, and so on are calculated.

desired queue

The difference between the output and input of a work cell required by the user. This value is the default for initial queue calculations.

detailed cost component

A cost component that contains non-aggregated costs.

These costs originate directly from:

- Surcharges

- Operations

- Purchase

Detailed cost components result in a price structure where all costs have been broken down.

Production order costs, production variances, and production surcharges are calculated and posted by detailed cost component. However, in inventory, the goods are calculated and posted by the three aggregated cost components.

disaggregate

A process that splits a family into smaller families, or into items.

Disaggregation is used in planning procedures, for example, to split the demand plan or the production plan.

The split is based on a disaggregation rule, such as one of the following:

- Planning percentages (defined in the aggregation relationships)

- Inventory

- CTP volume

You can also disaggregate items that are not part of a family.

earliest finish date

The earliest date an activity can end, taking into account previous and next activities and the company calendar.

The earliest finish date can be calculated for activities in the network planning and for operations in the production planning.

effective date

The first date on which the relevant standard cost takes effect.

effective date

The date on which the validity of the materials or the operations is checked.

The application considers a material or operation to be valid, if this date is within the effective date and the expiry date range.

The effective dates are used in the explosion process to create demands for the correct items.

efficiency variances

A part of the production result that is created by differences between the estimated and actual material quantities and hours.

The efficiency variance shows how efficiently materials and resources are used.

end item

An item that is ready to be delivered to a warehouse. An end item is produced at the end of a dangle routing (co-products and by-products) or a main routing.

engineering item

An item in the process of development.

You can define multiple revisions of an engineering item. Typically, the most recent revisions are still in a design or test phase, another revision may have been taken into production, and older revisions are obsolete.

A normal item can only become revision-controlled when it is copied from the Engineering Data Management module.

E-item

engineering item relationships

A link between a particular E-item revision and one or more standard or customized items. You can use the relationship to implement a design change incorporated in a new E-item revision by copying the E-item data to the item defined in the relationship.

engineering module

In Assembly Planning, a system, or, in other words, a logical unit of assembly parts, that is typically not manufactured as a separate physical unit.

For example, the electrical system of a car is the logical unit of all parts required for the electrical system. It is, however, not manufactured as a separate physical unit, but integrated in the dashboard, doors, and so on.

An engineering module has no routings, assembly lines, options, and so on, and is for design and planning purposes only. In the bill of materials (BOM), the engineering module is the top layer of the nonconfigurable section of the BOM.

enterprise planning order group

A user-defined group of planned production orders.

estimated quantity

The quantity of an item that is planned for use in a particular production order.

The estimated quantity is made up of the net quantity plus any additional quantities used to compensate for anticipated material losses.

exchangeable configuration

A configuration is exchangeable with another configuration at a particular point on the assembly line, if at that point the two configurations have the same specifications.

exponential smoothing

A demand forecast method that takes account of recent data over and above past data.

family

In Product Classification, a collection of items with common features.

family structure

A multilevel hierarchy (tree) of product families. Product families are part of a main family group. Lower family groups can be linked to a higher family.

FAS item

A generic item with the FAS (Final Assembly Scheduling) order system.

FAS items are produced in a mixed model flow process on an assembly line.

feature

A property of an item which is used when you classify items. For example, a frame and a wheel are features of the item bike.

feature

Characteristics which can be combined and subsequently be linked to configurable items to compose a product variant. An example of a feature is color.

finalize

The final action when you actually copy data from engineering bills of material (EBOMs) to production bills of material.

To copy data, you can either use mass BOM changes (MBCs), or manually copy the BOM lines.

fixed costs

Expenses that do not vary with the production volume. Examples of these costs are the depreciation costs of machines and buildings, rent, and property taxes. Operation rates and surcharges can be attributed to the variable costs or the fixed costs.

Antonym: variable costs

fixed duration

An indication whether the production time is fixed, or is dependent on the order quantity. If the production time has a fixed duration, then it equals the cycle time. If it is indicated that the production time does not have a fixed duration, the cycle time is multiplied by the order quantity.

For example, baking one bread in the oven takes one hour. Baking a hundred breads at once also takes a fixed duration of one hour.

flatten

To bring down a multilevel structure to one level. As a result, all elements of the hierarchical structure are the direct children of the parent item. This process can be used to enhance the calculation of assembly part requirements.

Example

Once in while, a product structure is flattened, and the result is stored separately. This way, LN does not need to browse the structure each time the assembly part requirements are calculated, because all parts that are required can be read at once.

float time

The time between two activities, expressed in days.

Example

If activity A and activity B have a end-start relationship with a delay of three, the network planning shows that activity B starts three days after activity A has finished.

floor stock

A stock of inexpensive material present in the job shop that can be used in production without recording each issue of material individually. Floor stock is not backflushed and is not part of the estimated costs.

freeze

To deactivate line stations, line segments, line station orders, and the like. If something is frozen, no changes are allowed. For example, a line station order can be frozen because the production process is too far advanced to be able to process the change.

Standard cost valuation method

Standard cost valuation is an inventory valuation method. The standard cost is a calculated inventory value, based upon calculated material costs, operation costs, and surcharges. The standard cost valuation includes the surcharges by warehouse.

generic item

An item that exists in multiple product variants. Before any manufacturing activities are performed on a generic item, the item must be configured to determine the desired product variant.

Example

Generic item: electric drill

Options:

- 3 power sources (batteries, 12 V or 220 V)

- 2 colors (blue, gray).

A total of 6 product variants can be produced with these options.

generic price list

A product variant that is generated from customer specifications can have a detailed sales price based on the selected options. Purchase prices for generic items can also be generated. The purchase price is used to calculate the standard cost. Matrices can be defined if options exist for different product features that have mutual relationships that influence the purchase or sales price.

inspection note

An order document on which the inspected and approved quantities of finished products can be recorded.

instrument

A tool that is used during quality tests to measure particular characteristics of an item.

Example

| Instrument | acidimeter |

| Characteristic | pH value |

item subcontracting

The entire production process of an item is outsourced to a subcontractor.

item surcharge

An item surcharge is the basis for extra costs or discounts (in terms of percentage of fixed amounts) in the cost/valuation price structure for items belonging to the given item group or warehouse. Surcharges are linked to a price calculation code.

Kanban label

A document that authorizes the movement of goods to the job shop, between operations, or from the job shop. Previously called pull note.

lead time

The time between the production start date and the delivery date. The lead time can include order preparation time, transportation time, and inspection time.

lead-time offset

The cumulative lead time of the production process, calculated from the production stage where the relevant critical material or critical capacity is required to the final stage of the production process. The lead-time offset is a factor in determining the start date of the critical material or critical capacity requirement.

The lead-time offset can be expressed in days or hours.

lifetime serial number

A number to identify a tool. A lifetime serial number can be, for example, a combination of the functional number and the year of acquisition. Lifetime serial numbers are used to group the components of a multipiece tool.

Multipiece tools without a lifetime serial number can have components linked either with or without lifetime serial numbers.

Example

A multipiece tool X has a life time serial number 1990. One of the following must be true for the tool's components:

- The lifetime serial number of the components is the same as the multipiece tool (that is, 1990).

- The components that are linked to the multipiece tool do not have a lifetime serial number.

line mix

A set of production orders that are produced successively on an assembly line. Before production starts, the line mix is sequenced to determine the order of production.

line segment

A set of consecutive assembly-line work centers on an assembly line between two buffers. The first buffer is the beginning of the segment, the next buffer is the first part of the next segment.

line sequencing

The determination of the sequence order used to start the production of items in a segment of a production line. The sequence order may be changed from one line segment to the next.

line station

A work center that is part of an assembly line. A line station is used in the production of FAS (final assembly schedule) items. A line station can have multiple positions, which enables more than one item to be present in one line station.

line station order

Production order for an assembly line station.

line-station variant

Holds identical operations and materials that are used at a specific line station for multiple assembly orders. In this manner, the identical operations and materials are stored only once, rather than for each assembly order. When line station variants are used, less data storage is required, and the performance is enhanced.

Example

You produce cars with various features, including two types of wheels: broad and narrow. In the wheel line station, in which the wheels are fitted, all cars with broad wheels are one line station variant, and cars with narrow wheels are another line station variant, regardless of any other specifications, because the other specifications are not relevant to the wheel line station.

LSV

machine

In LN, a mechanical object on which operations can be carried out to produce items.

Machines are linked to operation rates. The operation rate and the labor rate together form the basis for the actual costing of production orders.

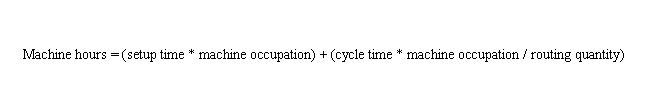

machine hours

The machine capacity in hours required to carry out the operation.

The formula LN applies to calculate the machine hours depends on whether or not the operation has a fixed duration. If the operation has a fixed duration, LN applies the following formula to calculate the machine hours:

If the operation does not have a fixed duration, LN applies the following formula to calculate the machine hours:

main assembly line

An assembly line that produces end products. An assembly line is a set of consecutive line stations where FAS (Final Assembly Schedule) items (and sometimes other item types) are manufactured.

main item

The end result of a production order.

A main item is either be changed to an end item (for delivery to a warehouse), or delivered directly to the customer in bulk.

main work center

A work center that is subdivided into subordinate work centers.

labor hours

The labor capacity in hours required to carry out the operation.

The formula LN applies to calculate the labor hours depends on whether or not the operation has a fixed duration. If the operation has a fixed duration, LN applies the following formula to calculate the labor hours:

Man hours = (setup time * man occupation for setup) + (cycle time * man occupation for production / routing quality)

If the operation does not have a fixed duration, LN applies the following formula to calculate the labor hours:

Man hours = (average setup time * man occupation for setup) + (cycle time * quantity planned input * man occupation for production / routing quantity)

mass BOM change

A mechanism to simultaneously make multiple changes to the engineering bills of material of several items.

You can use mass bill of material changes to concurrently carry out several of the following actions:

- Modify EBOM lines

- Copy E-item revisions to production items

- Copy EBOMs to productions BOMs

MBC

master company

In a multicompany situation, a master company is used to synchronize data in all companies. Data that is entered or generated in the master company, for example, the line structure, can be replicated to the other companies. The master company can either be one of the companies of the assembly lines, or a separate company.

material

The raw materials, components, and subassemblies used to manufacture an item. A cost item, for example, electricity, can also be treated as a material.

material issue note

An order document that reports the estimated, allocated, and issued quantities of required materials for a production order.

If you are using JSC order groups, you can combine the material for all the production orders in the group into one document, the collective material issue note.

material list

An order document that is used to report the material requirements of a production order. The document reports both the estimated quantities and the inventories on hand of the materials.

mathematical operator

Denotes or performs a mathematical operation or function; for example, add (+) and subtract (-).

microrouting

A series of steps that is linked to a routing operation to which you can connect instructions, tools information, and process information. When a production order is released, the information that is linked to the operation steps is given to, for example, the job shop operators to support their jobs.

minimum order quantity

The minimum quantity of items to be purchased or produced. When planned orders are generated, the quantity of items to be purchased or produced is never less than the minimum order quantity. The minimum order quantity prevents the purchase or production of this item in quantities that are too small.

module

A planning unit for a customized, manufactured, or purchased part, for which the logistical planning is related directly to the project network planning. A module may be a more or less complex compound part or a single part, such as a long delivery time part.

move time

The time that a semifinished good is in transit from one operation to the next operation. After the last operation, the move time is the time required to transfer the finished good to the warehouse.

Move time is one of the lead-time elements LN plans according to a specific calendar.

moving average

The average value of the present inventory, which is used in order to calculate the administrative price when you issue inventory. The inventory value is based on historical purchase prices.

multilevel bill of material

A BOM that lists the subcomponents of the components, and any eventual subcomponents.

In the multilevel BOM, the final product is at level zero.

multipiece tool

A tool with detachable components that operate together during an operation.

Example

A die is used for fixture. The die is made up of the following components:

- Top die

- Bottom die

- Punches

- Guide pillars

The die is defined as the multipiece tool, and the pieces are defined as the components.

net quantity

The quantity of a component or material that is theoretically required to manufacture a certain quantity of a product.

This quantity is referred to as the net quantity because in practice you may require more than this quantity to make up for certain losses of material or product during the production process.

network planning

The network planning includes all the activities required to carry out (plan and control) a project. The relations within the network show the interdependent activities.

norm table

A table that contains the times required to perform a task (norm times), or the numbers of times that a task can be performed in a specific unit of time (norm units). The norm times or norm units depend on two series of values presented in the columns (X-axis) and the rows (Y-axis) of the table.

Example

The time that it costs to drill a hole depends on the material's thickness, and the hole's diameter. A norm table that contains norm times can look like this:

| Thickness (mm) | ||||

| Diameter (mm) | 1 | 2 | 3 | 4 |

| 0.5 | 1.2 | 1.4 | 1.6 | 1.8 |

| 1.0 | 2.2 | 2.5 | 2.8 | 3.1 |

| 1.5 | 3.1 | 3.5 | 3.9 | 4.3 |

The norm time to drill a hole with diameter 1.0 in a material with thickness 2 is 2.5.

norm time

The time that is required to perform a task. That time is determined on the basis of two values in the norm table.

Example

To drill a hole with a diameter of 5 mm (first value) in a sheet with a thickness of 8 mm (second value) takes 0.5 minute (norm time).

norm unit

The number of times that a task can be carried out for a specific unit of time (minute or hour). That number of times is determined on the basis of two values in the norm table.

Example

Each minute, 5 boards with a thickness of 5 mm (first value) and a width of 60 mm (second value) can be sawn. Consequently, the norm unit is 5.

normal capacity

The average capacity of a machine or work center that is used as the basis for the capacity utilization.

basic capacity

offset

The cumulative lead time of the production process. The offset is calculated from the production stage, which requires the relevant critical material or critical capacity, to the final stage of the production process. The lead-time offset is a factor in determining the start date of the critical material or critical capacity requirement.

offsetting

To plan orders to account for the cumulative lead-time of the production process.

operation

One of a series of steps in a routing that are carried out successively to produce an item.

The following data is collected during a routing operation:

- The task. For example, sawing.

- The machine used to carry out the task (optional). For example, sawing machine.

- The place where the task is carried out (work center). For example, woodwork.

- The number of employees required to carry out the task.

This data is used to compute order lead times, to plan production orders and to calculate standard cost.

operation note

An order document that contains all the information required to carry out an operation. This document is also called a job sheet.

operation rate

A rate that is determined by labor costs, machine costs, or overhead costs. The operation rate can be linked to work centers or tasks by an operation rate code.

operation rate code

A code that identifies operation rates (labor costs, machine costs, or overhead costs). The code can be defined at different levels, and in order of priority be related to the reference operation, machine capacity group, work center and production department's calculation office.

operation set

A set of operations consecutively carried out at the same work center.

operation status

The status assigned to an operation. For example, Planned, Ready to Start, or Completed. This status indicates how far an operation has proceeded.

operation step

A suboperation connected to a routing operation.

An operation step can contain information such as, instructions, process information, and tools information.

operation subcontracting

The work on one or more operations in an item's production process is outsourced to a subcontractor.

option

Options per product feature are aspects that specify the product feature. For instance 'red' can be an option of the feature 'color'.

option combination

A specific combination of product options, for example, color or style, that are related to an assembly order.

Each option combination is either a single option, or a combination of other option combinations.

option set

Identifies a set with product features and options for a configurable item within the product structure.

order block

A group of production orders that have the same setup states and are produced on the same machine.

Production orders with the same setup states can be executed on a machine without changing the machine’s setup.

order costs

The (administrative) costs for placing an order. Order costs include the handling and transportation costs. The costs of the purchasing department, production planning department, and control department incurred by a production order or a purchase order.

order interval

The number of workdays or working hours for which all the requirements of a specific item are bundled in one (planned) order, during an order planning run. LN calculates the order interval from the day when the first requirement occurs. Order intervals are used to prevent an excessive number of planned orders in one time period.

order quantity increment

The size of the step by which the order quantity can be increased.

The recommended order quantity must be a multiple of the quantity that you specify as the order quantity increment. LN verifies this when planned orders are generated.

Example

If the required order quantity is 62 and the order quantity increment is 8, then LN recommends an order quantity of 64.

order quantity multiple of

partial delivery

The delivery of a part of the total order quantity.

penalty cost

Theoretical costs for not meeting rules on an assembly line.

person hours

The unit of work equal to one person working for one hour. The terms man-hours and person-hours are used interchangeably.

phantom

An assembly that is produced as part of a manufactured item, and that can have its own routing.

A phantom is usually not held in inventory, although occasionally some inventory can exist. The planning system does not create material requirements for a phantom, but drives the requirements straight through the phantom item to its components. Phantoms are mainly defined to create a modular product structure.

Example

The door of a refrigerator is defined as a phantom item in the bill of material of a refrigerator. The materials of the door are listed on the production order's material list for the refrigerator.

physical location

The room, building, or construction site where an operation is carried out.

pivot segment

The segment from which LN starts generating sequences.

plan item

An item with the order system Planned.

The production, distribution, or purchase of these items is planned in Enterprise Planning based on the forecast or the actual demand.

You can plan these items by means of the following:

- Master-based planning, which is similar to master production scheduling techniques.

- Order-based planning, which is similar to material-requirements planning techniques.

- A combination of master-based planning and order-based planning.

Plan items can be one of the following:

- An actual manufactured or purchased item.

- A product family.

- A basic model, that is, a defined product variant of a generic item.

A group of similar plan items or families is called a product family. The items are aggregated to give a more general plan than the one devised for individual items. A code displayed by the item code's cluster segment shows that the plan item is a clustered item that is used for distribution planning.

plan level

The level within a hierarchical planning structure.

When you plan on a higher plan level, plans are general and less detailed.

Example

Plan level 1 is the highest plan level; the higher the number, the lower the plan level.

planned input

The total input quantity of a work center/machine for operations that is planned to be Ready to Start during the target period.

planned output

The total output quantity that you plan to report complete, for operations at a work center/machine during the target period.

planned queue

The planned input minus the planned output of a work center/machine.

planning percentage

The planning percentage determines how a plan item is disaggregated over its subitems.

Example

If the total demand for bicycles is disaggregated over the various types of bicycles, the demand for racing bikes is 49% of the total demand.

cost calculation code

A specification of how a standard cost, valuation price, or sales price is calculated. The code stores specific cost calculation data.

The price calculation code that is defined in the Standard Cost Calculation Parameters (ticpr0100m000) session determines the standard cost. Other cost calculation codes are used for simulation purposes. The price calculation code for customized items is stored by project.

Example

- Specific operation rates

- Subcontracting rates

- Simulated purchase prices

- Surcharges

price list matrix

During the product configuration or product generation process price list matrices can be used to determine specific purchase and sales prices. Price list matrices can be used for recording prices, price factors, and also surcharge and discount percentages for a product variant.

Tables with prices which are based on the values of a physical quantity on the X-axis and the values of a physical quantity on the Y-axis.

price variances

The price variance of a production order is the part of the production result created by differences between the estimated and actual price of an item or hour.

The price variance indicates the effect of changing rates and prices on the production result.

primary work center

A work center that performs production for other companies. A primary work center cannot be modeled in a routing. It is used for capacity planning and displays the total capacity requirements of the related secondary work centers.

The production is administratively performed in the secondary work centers, which can be in the same or in a different logistic company than the primary work center.

This enables you to plan and carry out work in several different logistic companies (if you define several secondary work centers) without having to use sales orders and purchase orders.

process variable

A setting or an input value related to a machine, a tool, or to process quality that is relevant to carry out an operation or an operation step. For example, cutting depth, cutting speed, and temperature.

process-triggered workflow

Workflow in which actions are triggered by an activity, or batch or activities, in another line station.

product expiry date

The date that indicates an item's shelf life.

product family

An item that represents a group of similar plan items (or families). The items are aggregated to give a more general plan than the one devised for individual items.

The aggregation relationships specify the percentage of each plan item in the product family.

Use product families with care. A product family does not normally have its own BOM or routing. However, you can create production orders or sales orders for a product family, though this can lead to inconsistencies in the planning.

product model

Used in the definition of the product variant in making a sales order or quotations by translating the customer requirements into a product variant

product structure

The sequence of steps by which components are put together to form subassemblies, until the finished product is produced.

The product structure is defined by a multilevel bill of materials, sometimes in combination with routing data.

product variant identification code

The unique identification of a product variant.

Product variant codes make it possible to generate various variants for a configurable item. Specially if a customer wants information about options and prices without any obligation. In the implementation stage of the product model, it is also used to execute system tests.

product variant structure

The structure of the product variant, which consists of one configurable end item that is related to several configurable sub-items and/or engineering modules.

Configurable sub-items can also have their own configurable sub-items and/or engineering modules. The configurable items represent the product and the subassemblies of the product. The engineering modules are used for assembly items and represent logical units that may not constitute independent products, such as an electrical system. The product variant structure is generated by LN and, dependent on the options, holds a part of the bill of material.

production BOM

A general, multilevel list of all parts, materials that go into a manufactured product and show the quantity of each of the parts required to make the item.

PBOM

production bill of material

production item

An item that occurs in any module of Manufacturing. It is a product or generic item that is used in a generic/production bill of material or in a generic/production routing.

production order

An order to produce a specified quantity of an item on a specified delivery date.

production order status

The status assigned to a production order, which indicates the process stage of a production order. For example, Created, Printed, or Released.

production rate

The quantity of items that is produced for a specific time unit.

Example

The production rate can be, for example, 300 gallons per hour, or 20 pieces per minute.

production schedule

A period of time in which product is manufactured in the Repetitive Manufacturing module for a specific reason and linked to a cost document. The period length can be defined by the user.

production time

The lead time required to execute an operation.

The production time includes the setup time and the run time. The formula LN uses to calculate the production time depends on whether or not the corresponding operation has a fixed duration.

-

In case of a fixed duration, the formula LN applies to calculate the production time is:

average setup time + cycle time -

If the operation does not have a fixed duration, the formula LN applies is:

average setup time + (cycle time * quantity planned input) / routing quantity

project

A collection of manufacturing and purchasing actions that are performed for a particular customer order. A project is initiated to plan and coordinate the production of the to be manufactured items.

For a standard-to-order production, the project is only used to link the item with the customer order. A project can also include these:

- Customized item data (BOMs and routings)

- Project planning (activity planning)

project activity

An activity that is relevant for the (rough) planning of a project. Activities are used to plan the rough material and capacity requirements of the project. Activities are also used to control the (final) assembly planning of the project.

project item

An item that is produced or purchased for a particular sales order. The item's project provides a link with the sales order.

A project item can be recognized by its item code. If a code has been entered in the project segment, the item is a project item.

A project item can be customized to the specifications of a customer, but it can also be a standard-to-order item.

project part

A separate part of the project structure that is linked to a project. A project part is the basis that is used in order to determine the estimated costs of a project. Not to be confused with a subproject.

project structure

The project structure indicates the subprojects that belong to the main project. Project structures are especially important where there are extensive projects in an engineer-to-order situation.

Project structures can be important for network planning. This is because the start dates and finish dates of subprojects can depend on the computed start dates and finish dates of the main project's activities.

The costs of subprojects are aggregated to the relevant main project in the project calculation.

The project structure only applies to a project with a type other than Budget.

You can only delete a project structure if the main project has the Free or Archived status.

quantity extra

The product quantity that is assumed to have disappeared in the operation due to a limited yield, for example, the quantity lost through evaporation. This only applies if a yield has the type Continuous.

The quantity is referred to as quantity extra, because an extra quantity of the product must be planned to compensate for the loss.

quantity ordered

The quantity to be produced in a production order.

quantity planned input

The quantity that should be given as input to an operation to get the required output, taking into account scrap quantity and yield percentage, and quantities reported completed and rejected.

The quantity planned input is the quantity of products on which calculations of materials and hours are based.

quantity planned output

The quantity of the product that you expect to come out of the operation, taking into account scrap quantity and yield percentage, and quantities reported completed and rejected.

When LN creates a production order, the quantity planned output of the last routing operation is set equal to the order quantity of the production order. When the operation is not the last one, the quantity planned output is equal to the quantity planned input of the next operation.

question

A question is used during the classification of, and search for items. The user must respond with an answer. In the Product Classification module (GRT), LN asks the question with a question-and-answer type of user/system interaction.

queue deviation

The difference between the planned queue and the actual queue on the generation date, that is actual queue minus planned queue.

queue time

The amount of time that an order remains at a work center before setup, or work is performed.

receipt note

An order document on which the completed quantities of the products can be recorded.

receiving site

The site (plant) on a receiving point of the supply chain.

reference designator

Indicates the location to insert a component on an item, for example, where to mount an electronic component on a Printed Circuit Board. Reference designators are often used in electronics, and can originate from a Computer-Aided Design (CAD) station.

reference type

A product variant may relate to a sales quotation, sales order, budget or project, or it may concern a standard variant.

refurbishing

The renovation of a tool after a number of usages.

rejected item

A product that does not meet the quality standards set for the end product or subassembly. Also called a reject

repetitive item

A repetitive item (also called RPT item) is a manufactured item whose production is controlled by schedules. A schedule contains multiple schedule lines that can be viewed, released, reported as complete, and so on, in one session.

A repetitive item characteristics:

- Produced in large quantities

- Subject to repetitive demand

- Production is based on a rate

- Lead time is short

Anonymous items and to-order items can be repetitive. However, only to-order items that are Standard-to-Order can be used in RPT schedules. You cannot use generic items or Engineer-to-Order items in an RPT schedule.

rescheduling message

An order signal that informs the planner whether an order must be expedited (rescheduled in), delayed (rescheduled out), or canceled.

result

The financial results of, for example, a project or a production order. The results are reported in terms of variances. A variance is the difference between the expected (budgeted or planned) value and the actual value. You can distinguish between price variances, efficiency variances, and additional calculation-office variances.

return value

The code that is included in the classification code as a result of the selected answer.

revision

A version or revised version of an engineering item (E-item) or a revision-controlled item, that is, an item linked to an E-item. Several revisions of an E-item can exist.

Example

E-item: Mountain bike E-MB01

| Revision | Description | Status |

|---|---|---|

| A1 | Draft drawing of bike | Not released |

| A2 | Drawing of bike | Not released |

| A3 | Parent E-item of bike MB01 | Released |

| A4 | Obsolete bike | Canceled |

revision-controlled

The revision-controlled items are items in continuous development. To identify the item's version, add a revision number to the item code.

If a revision-controlled item is selected, the current version is used. The obsolete versions are no longer manufactured and prototypes are not sold yet.

rework order

A production order to fix or upgrade an already produced or purchased item. The item that must be reworked is both input and output of the production order.

roll-off line

The assembly line where a product is completed.

routing

The sequence of operations required to manufacture an item.

For each operation, the reference operation, machine, and work center are specified, as well as information about setup time and cycle time.

routing code

A code that is linked to a routing. A routing code can be linked to a standard routing or an item-specific routing.

routing quantity

The quantity of the manufactured item on which the routing is based. A routing quantity enables you to include very short operation times in the routing of an item.

Example

| Routing quantity | 100 |

| Cycle time | 60 minutes |

In a 60 minute time span, 100 items are produced. Consequently, the operation time of one item is 0.6 minute.

routing sheet

An order document that lists all the operations required to manufacture an item, as well as the required tools. A routing sheet can also contain microrouting information that provides the operators with instructions or process information.

rule

Logical condition determining action.

run time

The time required to process a piece or lot at a specific operation.

Run time does not include setup time.

run time = production time - setup timesales price structure

Gives insight into the structure and composition of the sales prices for product variants.

The sales price structure:

- Is used when calculating the sales price for a product variant on a sales order or sales quotation.

- Provides insight into the price structure and can be displayed in the Product Variant Sales Price Structure (tipcf5530m000) session. In addition to or instead of the product variant options, it can be printed on sales order documents.

sawing list

An order document that lists the materials that must be obtained to saw a specified length of material from a large piece, for example, a pipe or a bar.

scheduling area

A physical area or part of the production line for which a production schedule is defined. Scheduling areas are defined for repetitive items.

Scheduling areas relate to the production orders of items with routings that employ virtually the same production facilities. A scheduling area is related to a production schedule code.

Scheduling areas are used:

- To define routing codes by repetitive (RPT) item in the Item - Routings (tirou1101m000) session.

- As a selection criterion in the Report Orders Completed Globally (tisfc0206m000) session and the Backflush Materials and Hours (tisfc0220m000) session.

Example

| Scheduling Area | Schedule Code | ||

| HHA | Household appliances | WL | Weekly |

| ELT | Electric tools | 2WL | biweekly |

scrap

Unusable material or rejects of intermediate products, for example, because of faulty components, or products lost in cutting or sawing operations. The gross material requirements and/or an operation's input quantity must be increased to account for anticipated scrap.

In the BOM, you can define scrap as a percentage of the net material requirements, which is the scrap factor, and as a fixed quantity, which is the scrap quantity. A scrap quantity is mostly used to define the amount of material that is lost every time when you start producing, for example, to test the equipment.

For an operation, you can only define the scrap as a fixed quantity.

secondary work center

A fictional work center in which the production is performed administratively, whereas the actual production is performed in a different work center.

The secondary work center can be in a different logistic company than the primary work center to which it is linked.

This enables you to plan the work to a work center in your own logistic company, but have it physically carried out in a different logistic company without having to use sales orders and purchase orders. For each primary work center, you can define several secondary work centers.

segment schedule

A schedule that indicates when assembly parts are required. Based on the offline date of the assembly order, and the segment for which the assembly parts are required, the segment schedule indicates when the parts must be delivered to the line. Segment schedules are used for a rough calculation of assembly part requirements, when high volumes are processed, and the performance of the calculation is critical.

semifinished item

The product of a phantom routing, which is passed on to the next operation in the routing network.

setup class

A type of item characteristic that indicates how a machine must be set up to produce the item. The setup class determines the changeover time for a machine or a tool between two operations. A setup class consists of a series of setup states.

Example

Examples of setup classes are color and thickness. If your setup class is color, the setup states can be red, green, white, black, and so on.

setup class

another.

setup state

An item's characteristic that is linked to an operation. Depending on the setup states of two successive operations, a machine's changeover takes longer or less long. A series of setup states form a setup class.

Example

If your setup class is color, examples of setup states are red, green, white, black, and so on.

setup class state

The characteristics that determine the state of the machine.

The setup class states influence the required changeover time from one state to another. Setup class states are grouped in a setup class.

shared work center

A work center that can be used to perform operations for multiple companies that represent production sites. For this purpose, a primary work center is defined in the company where the production is performed. Secondary work centers are defined for the companies on whose behalf the production is performed.

A secondary work center has a relationship with the primary work center, with the available capacity defined. A secondary work center administratively performs the production in the company on whose behalf the actual production is performed.

shop floor warehouse

A warehouse that stores intermediate inventory in order to supply work centers. A shop floor warehouse is linked to an individual work cell, an assembly line, or one or more work centers. A shop floor warehouse can be supplied with goods using replenishment orders, or by pull-based material supply.

The pull-based material supply methods are:

- Order Controlled/Batch (only applicable in Assembly Control).

- Order Controlled/SILS (only applicable in Assembly Control).

- Order Controlled/Single (only applicable in Job Shop Control).

- Kanban.

- Time-Phased Order Point.

The items stored in the shop-floor warehouse are not part of the work in process (WIP). When items leave the shop floor warehouse for use in production, their value is added to the WIP.

shrinkage

The percentage of material lost due to a continuous process, such as evaporation or absorption.

simulated purchase prices

A simulated purchase price can be used to experiment with purchase prices and to compute the results.

simulation

The process of doing calculations using simulated figures instead of the actual ones to see what would be the result if certain figures were changed. Opposite term is actual or operational.

single-level BOM

An overview of components that are directly used in a parent item. A single-level BOM shows only the relationship one level down.

slack time

The time between the queue start date of the next operation and the setup + run start date of the next operation, calculated by LN.

Difference between the slack time and the queue time on the next operation can occur if:

- The calendars of the work centers differ.

- You apply a transfer batch quantity.

standard configuration

If an object (for example, a BOM line or a routing line) has a standard configuration, that object is selected when you are not using unit effectivity.

standard cost

The sum of the following item costs as calculated by the standard cost calculation code:

- Material costs

- Operational costs

- Surcharges

Prices that are calculated against other price simulation codes are simulated prices. The standard cost is used for simulation purposes and in transactions when no actual price is available.

Standard cost is also an inventory valuation method for accounting purposes.

standard item

A purchased item, material, subassembly, or finished product that is normally available.

All items that are not built according to customer specification for a specific project are defined as standard items. Opposite term is customized item.

standard-to-order (STO)

The production of non-customized items after receiving a customer order.

sub plan item

The identification of a plan item at a lower plan level.

subassembly

An intermediary product in a production process that is not stored or sold as an end product, but that is passed on to the next operation.

For subcontracting purposes, a manufacturer can send a subassembly to a subcontractor to carry out work on the subassembly. This subassembly has its own item code defined in the Item Base Data.

After work is finished, the subcontractor sends the subassembly back to the manufacturer. Also this reworked subassembly has its own item code defined in the Item Base Data.

subcontracting

Allowing another company (the subcontractor) to carry out work on an item. This work can concern the entire production process, or only one or more operations in the production process.

subcontracting note

An external order document that specifies a subcontracted operation and the corresponding data, such as the subcontractor, tasks, routing, and required materials.

subcontracting purchase order

In LN, subcontracting is considered as purchasing a service from a subcontractor. Therefore, when subcontracting, a subcontracting purchase order is generated to record the subcontracted operation(s) and the associated costs.

subcontracting rate factor

The subcontracting rate factor, together with the subcontracting base rate, determines the cost of subcontracting.

subcontracting rate

The rate that is used to calculate the subcontracting costs. How LN uses the subcontracting rate in the calculation depends on the calculation method:

- Unit

- Operation Rate

- Man Hour Rate

- Machine Hour Rate

sub-item

A means to further classify items.

A sub-item can either be:

- A component item used in a bill of material.

- A material used in a formula.

subsequent delivery

The quantity of the material that must be issued for the production order at a future date or time.

summarized BOM

A form of multilevel bill of material that lists all the parts and the quantities required in a BOM. Unlike the full multilevel bill of material, a summarized BOM does not list the levels of manufacture, and lists a component only once for the total quantity used. Phantom items are not listed.

A summarized BOM only contains purchased items, because all the manufactured items are made from purchased items.

supply in line sequence

The supply of assembly parts or assembly kits to a shop floor warehouse, so that they are delivered to the line station in the same sequence as the assembly orders.

supplying assembly line

An assembly line which produces subassemblies that are used in another assembly line. It may additionally produce items that are not used on any assembly line. An assembly line is a set of consecutive line stations where FAS (Final Assembly Schedule) items (and sometimes other item types) are manufactured.

surcharge

The indirect costs of an item, for example, overhead costs, storage costs, handling costs, and machine-maintenance costs. Surcharges can be defined as a percentage or as a fixed amount and can contribute to fixed and variable costs.

surcharge base

A set of cost components to which an item surcharge is applied.

target period

A user-defined period of whole numbers of days or weeks for which input/output data is generated.

task

An activity to manufacture or repair an item. For example, sawing, drilling, or painting.

A task is carried out on a work center, and can be related to a machine.

test

An examination or check done on a characteristic. You can link one or more tests to a characteristic.

time fence

A reference date against which processes or statuses are evaluated.

Example

The assembly order time fence on an assembly line defines the end date of the period for which assembly orders must be created. If this time fence is 100 days, assembly orders must be created for product variants whose planned offline date is between now and 100 days. Similarly, a time fence can define when line station orders must be frozen, updated, and so on.

time unit

The unit that is used to specify the physical quantity time.

tool

A reusable resource, manual or mechanical, that is used to perform manufacturing and/or service tasks. When you have finished with the tool, it is returned to inventory to be used for the next requirement. The tool's life is reduced each time you use it. A tool can be identified in LN as a unique combination of tool type and tool serial number.

Example

-

Hand tools

A saw or power drill. -

Machine tooling

A jig, mould, pattern or cutting tools. -

Instruments

A durometer or gauge. -

Equipment

A shovel.

tool component

A part of an assembled group of tool types.

tool kit

A set of specific tools required to perform a single task. A tool kit can be linked to a machine, a task, and/or a routing operation to specify the tool(s) required to perform the task and/or operation.

tool life

The capacity of the tool expressed in the number of hours or times it can be used.

tool number

A number to identify a tool. The combination of a tool type, for example, hammer, and a tool serial number, for example, 1, is unique, and identifies a tool in LN.

tool request

A tool request is created when a tool is required. One request is created for each tool/work center combination.

A tool request displays data relating to:

- Request number.

- Tool type

- Tool serial number

- Work center / service center

- Request status

How, where, and when the tool is used in the work center is determined by the tool request details, which can be found in the Tool Request - Lines (titrp0516m000) session.

tool request details

The tool request specifies at which work center or service center the tool is used. In addition, the tool request details specify when, where, and how the tool is used at the work center. The following production order details are displayed:

- Request number

- Request date/time

- Order type

- Order number

- Operation

- Line number

- Activity line

- Presence of the tool at the work/service center

tool serial number

A number to identify a tool. The combination of a tool type, for example, hammer, and a tool serial number, for example, 1, results in a unique identification of a tool in LN.

tool type

The tool type is the first level that is used to identify the tool in the coding system for tools.

Some examples of tool types are:

- Hammer

- Screwdriver

- Wheelbarrows

Hammer 1, screwdriver 2 and wheelbarrow 3 are examples of tool types in combination with a tool serial number, and represent unique tools.

transfer batch quantity