JSC - machines

New building blocks

These building blocks have been introduced for job shop manufacturing:

- Machine numbers

- Machine operations

The new building blocks are used to support these features:

- Report the production progress by machine

- Determine the overall equipment efficiency (future)

- Interface with a Manufacturing Execution System (IoT) (future)

- Schedule the work on the shop floor

- Manage the maintenance of the machine (future)

- Manage the purchasing, moving, depreciation and selling of the machine (future)

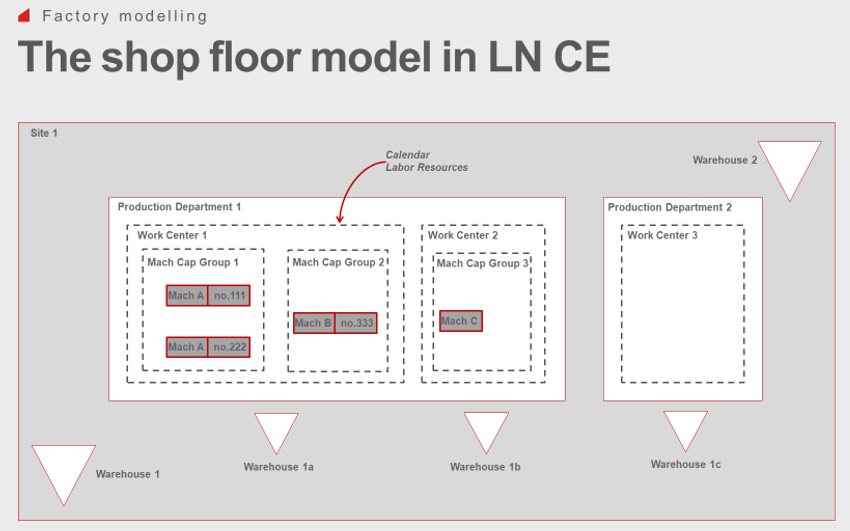

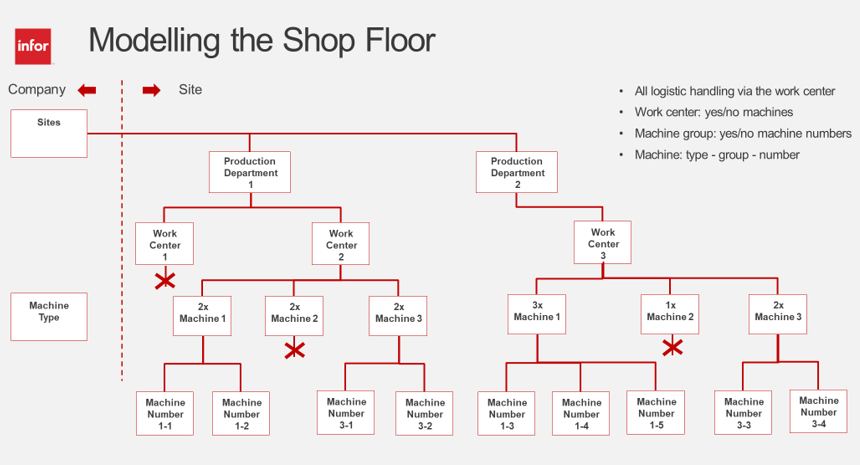

Extension of the shop floor model

To model the physical machine, the shop floor model has been extended with the machine number.

Previously, a start was already made to model the actual machine as part of a work center. The Machine, which could be used in the routing definition as a machine type or as a capacity group, was changed to Machine Type and the machine capacity group was added to the work center definition. Now, the Machine Number has been introduced to complete the model for the actual machine.

For each machine capacity group, it can be specified if the actual machines are modeled.

- Machine number

- Machine type (to which machine capacity group it belongs)

- Location (to which work center it belongs)

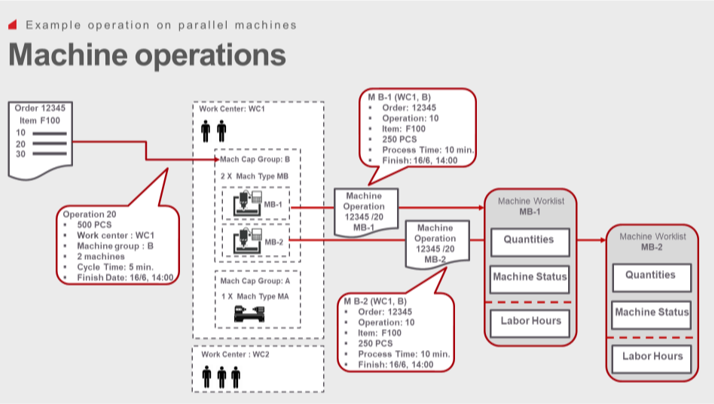

Machine operation

For each routing operation, it is specified on which machine capacity group the job must be performed and how many machines of the group must be used. The actual machines are assigned when the production order is created.

Assignment of a machine is done through the default sequence specified on the machine capacity group, manually, or if the new scheduler is implemented, by the scheduler.

The information regarding the production of the product on the selected machine is stored on a separate entity: the machine operation. When the production order is released, the machine operation is displayed on the machine worklist of the machine.

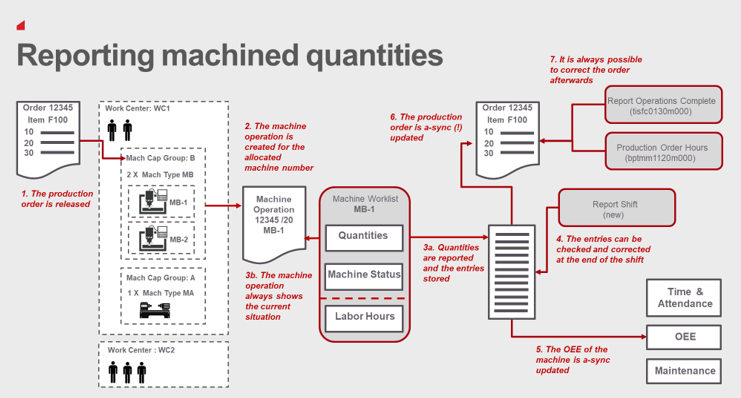

Reporting of produced quantities by machine

Reporting the produced quantities by machine, serves these purposes:

- Determine the production progress of a product. Ultimately, this information is stored on the production order (operation).

- Determine the efficiency of a machine. Ultimately, this information is stored in the performance indicators on the machine for each shift (OEE).

Previously, the reporting on the operations had to be done in sequence and the production order only stored the cumulative results. However, separate bookings for the OEE calculation and out of sequence reporting of operations are required.

To support these requirements, a new reporting process has been introduced:

- Each quantity booking is (temporarily) stored in a separate record.

- The total produced and rejected quantities are always updated on the machine operation.

- The reporting of quantities on the production order operation is done in a separate process, through the Aggregate Machine Operation Quantities (tisfc4201m000) session.

- The OEE is calculated at the end of the shift (not yet available).

Reporting of machine hours

The actual machine hours are not registered, but are calculated based on this data:

- The setting of the machine status through the machine worklist.

- The produced quantities (backflushing).

Reporting of shifts

At the end of a shift, a shop floor supervisor usually verifies if the registered quantities and the calculated machine hours are correct. The Report Shift (tisfc4112m000) session has been introduced to correct erroneous entries and to handle rejects. Subsequently, the entries can be booked to the production order.

Additionally, in a production order, corrections are based on “deltas”. For example, if 100 pcs are booked instead of 10, this is corrected through a -90 pcs booking. This booking method can distort an OEE calculation and is not in line with the bookings of some Manufacturing Execution Systems. Consequently, the mechanism for correcting quantity bookings has been enhanced. Now, an erroneous booking is corrected by two bookings: a correction of the wrong booking and an addition of the correct booking. In the above example, first a -100 pcs booking is done and then a booking of +10 pcs. All three bookings have the same transaction date (timestamp of the original transaction).

Update of the production order

Many scenarios are available for reporting the produced quantities, actual machine hours, and actual labor hours on the production order and the actual hours of the employee.

With the introduction of the actual machine, an additional level for reporting has been introduced. The machine worklist lists the planned jobs on the machine and is used to report the produced quantities and the actual spent machine hours.

The data is stored in new tables and is used to update this data for the applicable operation of the production order:

- Produced quantities

- Actual machine hours

Several sessions are involved to retrieve quantities and hours to update the production order and the employee hours.

The actual quantities for an operation are retrieved based on these methods:

- Automatic calculation, based on the reported quantity for the next operation (see the Reporting Method for Previous Operations field in the Production Settings by Site (timfc0180m000) session).

- Manual input in the Report Operations Complete (tisfc0130m000) session.

- Manual input in the JSC Operator Workbench (tisfc8350m000).

- Manual input in and update from the Machine Work List (tisfc4600m000) session.

The actual machine hours for an operation are retrieved based on these methods:

- Automatic backflushing based on the reported quantities.

- Manual input in the Production Order Hours (bptmm1120m000) session.

- Manual input in (start/stop) and update from the Machine Work List (tisfc4600m000) session.

The actual labor hours for an operation are retrieved based on these methods:

- Automatic backflushing based on the reported quantities.

- Manual input in the Production Order Hours (bptmm1120m000) session.

The actual hours for a named employee are retrieved based on manual input in the Production Order Hours (bptmm1120m000) session.

Reporting settings

The reporting of produced quantities and spent hours can be done in multiple ways, which is specified on the production order and the production order operations.

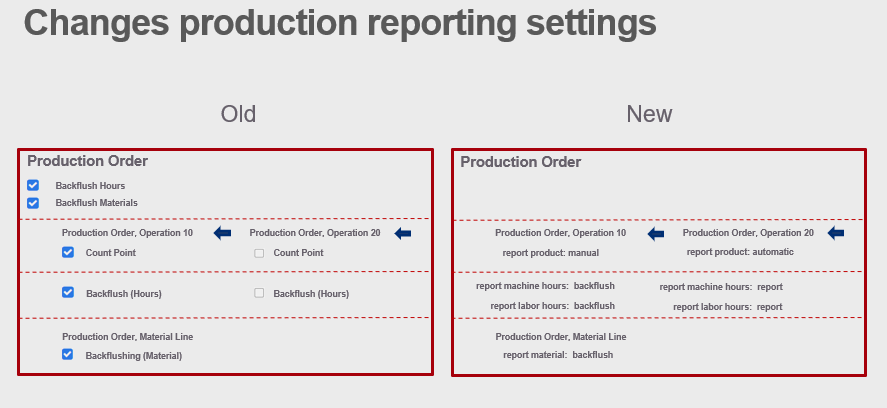

Previously, the reporting settings for machine hours and labor hours could not be specified separately. To allow for all logical combinations of reporting, this has changed in LN. The defaulting of the reporting settings has also changed.

Previously, the settings for backflushing hours and material on the production order header were used to support a mass change of the settings on the material lines and operations. In LN, this functionality has been removed.

Previously, the reporting settings for machine hours and labor hours could be specified on the production order operation with one parameter for both machine and labor hours. Now, the reporting settings for machine hours and labor hours have been split. Consequently, these reporting modifications have been made:

- Labor hours can be backflushed based on the reported quantities on the operation.

- Labor hours can be reported on the operation through LN People.

- Machine hours can be backflushed based on the reported quantities on the operation.

- Machine hours can be backflushed based on the reported quantities on the machine operation.

- Machine hours can be reported on the operation through LN People.

- Machine hours can be reported on the machine operation through the worklist.

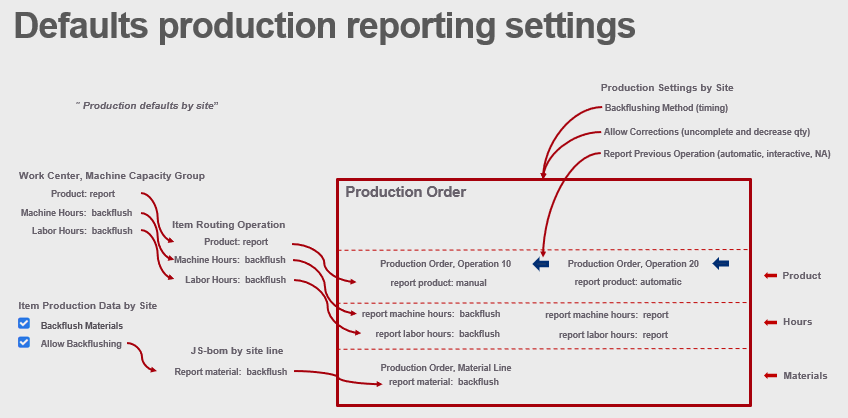

Defaulting of reporting settings

The settings for how reporting is performed, are partly specified on the production order and partly in the Production Settings by Site (timfc0180m000) session. To conform to the new reporting procedures, the defaulting of these settings has changed.

This two-stage defaulting applies to product reporting:

- Depending on the layout of the work center, the settings of either the work center, the machine capacity group, or the machine number are used to default the item routing operation.

- The settings on the item routing operation are used to default the production order operation.

This two-stage defaulting applies to machine hours reporting:

- The settings on the machine capacity group are used to default the item routing operation.

- The settings on the item routing operation are used to default the production order operation.

This two-stage defaulting applies to labor hours reporting:

- The settings on the work center are used to default the item routing operation.

- The settings on the item routing operation are used to default the production order operation.

This two-stage defaulting applies to materials reporting:

- The settings on the item production by site are used to default the job shop bill of material line.

- The settings on the item routing operation are used to default the production order operation.