JSC - order block sequencing

Some machining processes require extended setup time. This setup (changeover) time is significantly affected by the condition of the machine due to the previous task. Therefore, the sequence of the different operations on a machine over a period of time determines the total setup time.

Minimizing the cumulative setup time by sequencing the orders is a trade-off between advantages and disadvantages.

Advantages:

- Less setup cost

- Shorter throughput time, thus minimizing work in progress cost

- Better use of the bottleneck machine

Disadvantages:

- Higher inventory cost

- Late deliveries

The process of grouping and sequencing orders was already supported by the order block planning functionality. However, this functionality cannot be used if Job Shop by Site has been activated. To also support this scenario, the Order Block Sequencing functionality has been introduced.

Master data

New and extended master data has been added to support the order block sequencing functionality.

This master data is impacted:

- Settings

- Plan groups

- Machine capacity groups

- Setup class sets, setup classes and setup states

- Item setup states

Settings

In the Scheduler group box of the Production Settings by Site (timfc0180m000) session, these fields have been added:

- Maximum Number of Setup Classes: Determines how many setup classes can be specified in a setup class set. The possible values are 1, 2 or 3.

- Maximum Number of Setup States: Determines how many setup states can be specified in a setup class. The possible values are 1 - 12.

Enabling the production order sequencing functionality requires an activation process.

Plan group

The Work Center Plan Group (tisch0140m000) session has been extended with two check boxes to determine whether the scheduler or the sequencer is applicable for the plan group.

Machine capacity groups

In the Planning group box of the Machine Capacity Group (tirou4661m000) session, the Changeover Critical check box and Setup Class Set field have been added.

Setup class set, setup classes and setup states

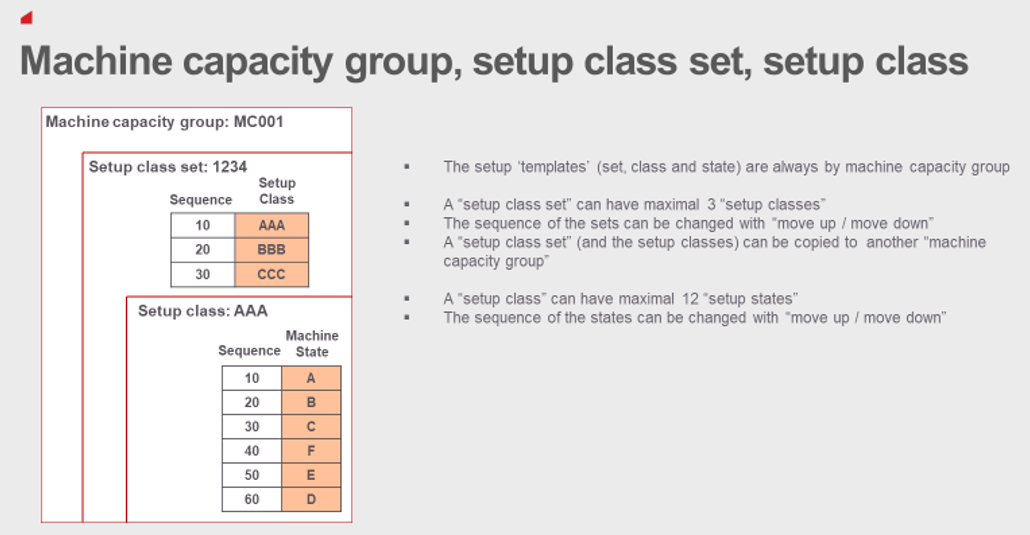

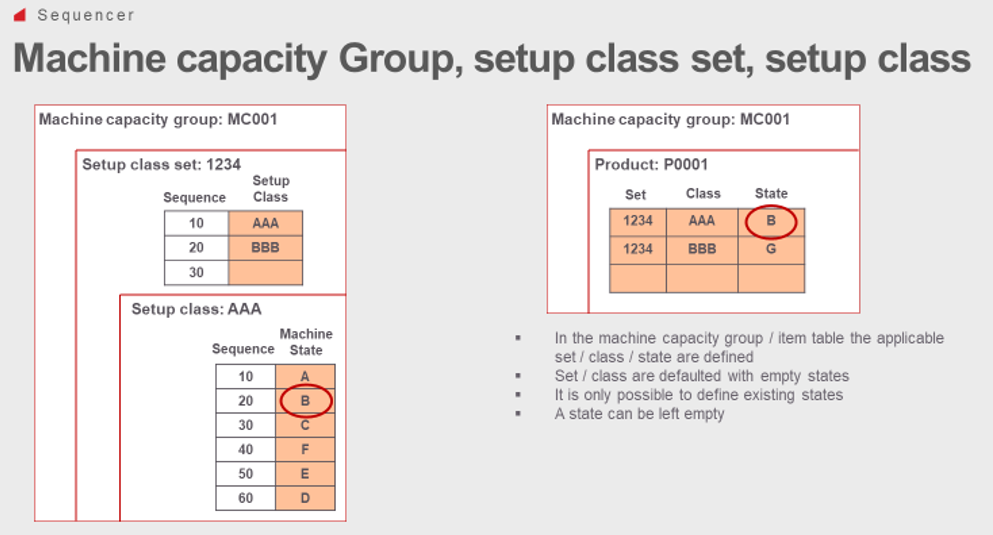

For each machine capacity group, a template for the (optimal) production sequence can be specified in the Setup Class Set (tirou4671m000) session.

In a setup class set, up to 3 setup classes can be specified. In a setup class, up to 12 setup states and their mutual sequence can be specified.

Item setup states

If the routing of a product uses a machine capacity group that is critical for setup, the setup states for the combination of machine capacity group and item can be specified in the Item – Setup Class States (tirou4675m000) session.

Only classes and states can be selected that have been specified in the setup class set of the machine capacity group. Classes or states can also be blank.

Process

The purpose of the order block sequencing functionality is to minimize the (actual) cumulative setup time on a given machine over a period of time (the order block run).

Order block sequencing is especially applicable to a shop floor where the supply chain has one fixed bottleneck machine with significant changeover variations.

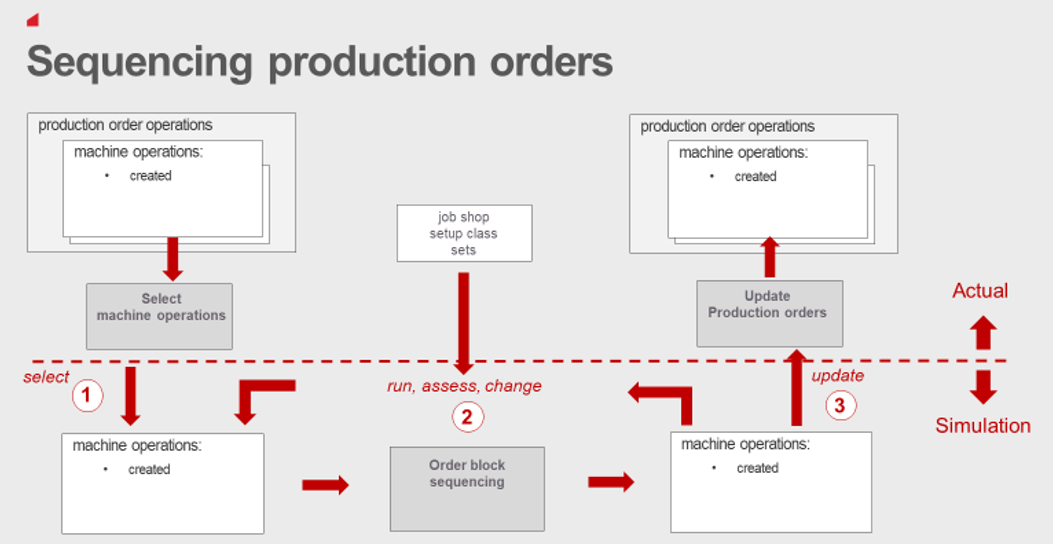

The machine operations that use the same (bottleneck) machine are sequenced. Based on the sequence templates, a sequence of machine operations is simulated on the designated machine. This sequence can be manually changed. Based on the simulation, the applicable job shop orders can be replanned.

Order block run

The order block sequencing functionality is run from the Order Block Runs (tisfc4120m000) session. In this session, these actions can be performed:

- Create the run

- Sequence the orders

- Analyze and manipulate the result

- Update the actual production orders

Supported scenarios

As for the existing order block planning functionality, these restrictions apply to the new order block sequencing functionality:

- Order block sequencing is done for one operation in an order

- The machine capacity group has one machine

- The setup time on the (machine) operation is not adjusted

- There is no check on the availability of the required material

- There is no check on the time-outs of the machine

- There is no check on already released orders

- There is no check on missed orders due to a missing setup class set in the Machine Capacity Group - Item – Setup Class Set table

- An order block cannot be split