SCH - production scheduling

Scheduling in LN

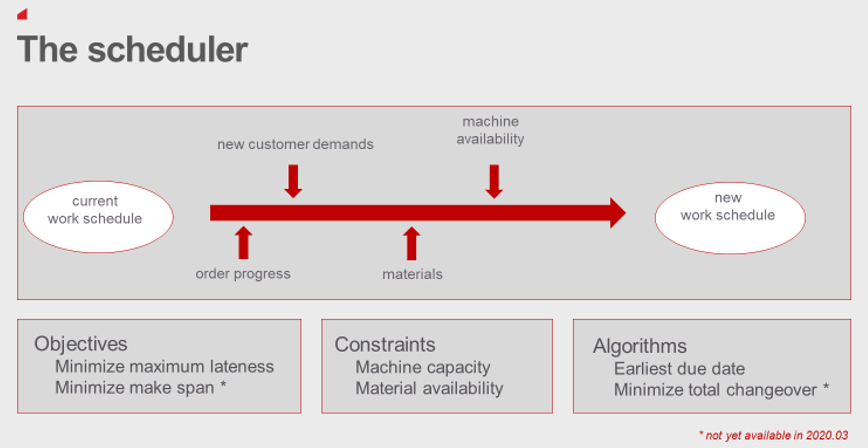

The Production Scheduler is new functionality in LN, which is housed in the new Production Scheduling (SCH) module.

Generally, the division between the area of planning and the area of scheduling can be very different. In LN, the new scheduler manipulates production orders and the planning handles planned orders.

In LN, the scheduler covers the very near future, up to a few weeks. The objective of the scheduler is to minimize the consequences of disruptions such as:

- Additional sales orders that are being accepted within the agreed lead time

- Materials delivered late

- Machine break downs

- Production backlog

- Schedules work only after the materials become available

- Prioritizes and sequence work based on rules

- Schedules work on the possible bottleneck machines against finite capacity

Scheduling process

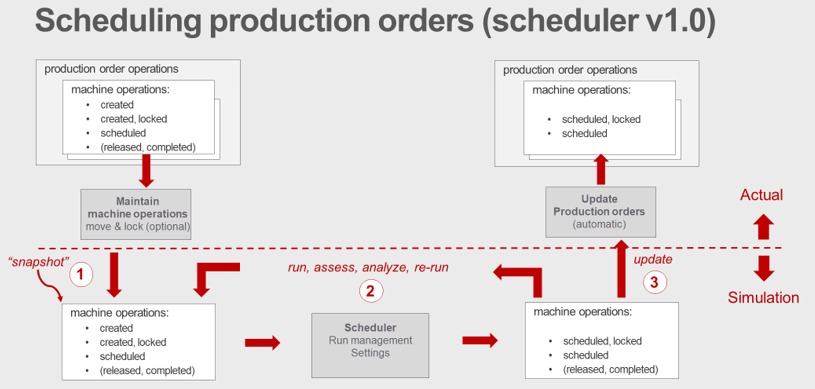

The new scheduling process is a simulation in a separate environment. The process includes these steps:

- Ensure all reporting is up-to-date. For example:

- All received purchased materials have been booked in inventory

- All production progress has been booked, checked and corrected

- All produced products have been booked in inventory

- All pegging relations have been generated

- Any (order) operation that may not be moved is locked

- Create the scheduling run and the snapshot

- The starting point is created based on the current situation (snapshot)

- It is stored in separate (SCH) tables

- The KPIs for the starting point are calculated and stored

- The settings for the run are maintained and stored

- Run the scheduler

- The scheduling is done based on the snapshot

- The results are stored

- The KPIs for the result are calculated and stored

- Compare the results (with the starting data)

- Between different scenarios

- Key performance indicators

- Machine operation schedules

- Lateness of specific orders

- In the operational environment, use the results to update:

- The machine operations

- The order operations

- The production orders

- Scheduling of the job shop is optional and is performed as an additional process.

- Comparing the results of two different scheduler setups is typically not done on the fly. Usually, one setup is used for the actual operation. An alternative setup is run in parallel for a longer period of time. The results are compared over time and, if feasible, the alternative setup becomes the actual one.

- A human planner can override the scheduler.

- Because the scheduler is run on a snapshot, the operational environment might have changed between the moment of taking the snapshot and the update based on the scheduler output. Consequently, the update process may partly fail and a report with the discrepancies is generated.

Job shop scheduler

The new Job Shop Schedule Runs (tisch1100m000) session is the central session for the scheduler. All functionality is run from this session.

The session provides an overview of all performed runs with the applicable statistics. The view is by site and the sort in reversed order (latest on top).

A run includes this data:

- The date on which the input for the run (the snapshot) is created

- The settings for the scheduler, such as the horizon, the objective, and the algorithm

- The KPIs of the input (snapshot)

- The KPIs of the output (result)

Schedule viewer

The new Schedule Viewer (tisch8350m000) session shows the workload of the machines of critical machine groups (possible bottlenecks). The viewer shows either the input (snapshot) or the output (result of the selected scheduler run).

The viewer includes these parts:

- The available capacity and utilization of the machines in the critical machine capacity groups for the time frame. The objective of this part is to assess the workload for the critical areas on the shop floor.

- The key performance indicators for the timeframe. The objective of this part is to provide an assessment of the current situation and a trend analysis over time.

- A Gantt chart with the applicable machine operations and their status. The objective of this graph is to show the result of the scheduling. It shows all critical machine operations and provides detailed information.

The time frame is the period between the scheduler time fence and the scheduler horizon as specified in the run.

The objective of the schedule viewer is to support an overall appraisal of the scheduling run results. It is not a workbench.

Scheduler setup and prerequisites

- Prerequisites

-

To use the job shop scheduler, these prerequisites are applicable:

- Each work center must be part of a plan group

- At least one bottleneck machine must be specified on the shop floor

- For all items, the operations on the bottleneck machines must be specified

- Machine time-outs must be specified

- Plan group

-

The plan group determines the boundaries of the scheduler. If the scheduler is enabled for a site, the plan group is mandatory for the work centers in the site. Consequently, each work center is always part of one plan group.

Production orders within a site are interwoven, because they are either part of the same supply chain, use the same materials, or use the same machines. Consequently, for a feasible production plan, all production orders for the site must be scheduled in one run.

However, a set of orders can be left out or can be scheduled independently. For example, a site where plastic injection molding parts (plan group 1), metal injection molding parts (plan group 2) and metal machined parts (plan group 3) are produced and delivered directly to the customer, can be run separately for each plan group with different scheduler settings.

- Bottleneck machines

-

The scheduler considers the available capacity of the bottleneck machines.

To schedule the work on an actual machine, that machine must be modeled by the machine number.

A machine number is part of a machine capacity group that can be marked as critical for scheduler. If marked as critical, the machines in the group are possible bottlenecks whose availability is considered by the scheduler.

- Machine operations

- The work on the actual machine is modeled as machine operations. If a production order has operations for a machine capacity group with machines, machine operations are created automatically.

- Machine time-outs

- The unavailability of a machine due to maintenance, break down, or replacement must be modeled as a machine time-out for the machine number.