Normal ballooning scenario

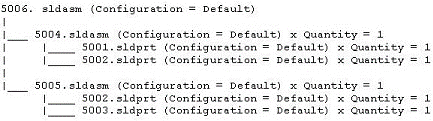

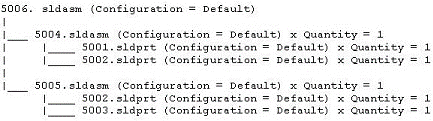

For example, consider the following structure:

| Parent Model | Parent Configuration | Child Model | Child Configuration | Quantity |

|---|---|---|---|---|

| 5006.sldasm | Default | 5004.sldasm | Default | 1 |

| -do- | -do- | 5005.sldasm | Default | 1 |

| 5004.sldasm | Default | 5001.sldprt | Default | 1 |

| -do- | -do- | 5002.sldprt | Default | 1 |

| 5005.sldasm | Default | 5002.sldprt | Default | 1 |

| -do- | -do- | 5003.sldprt | Default | 1 |

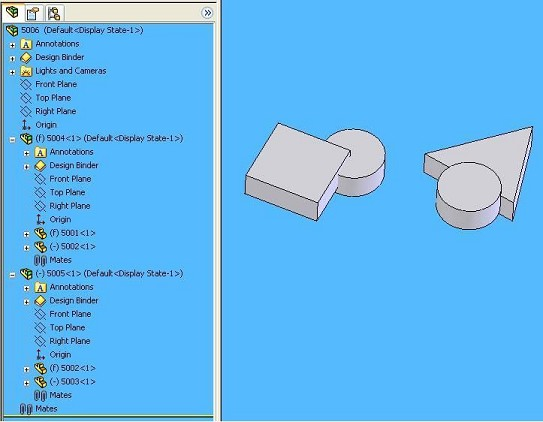

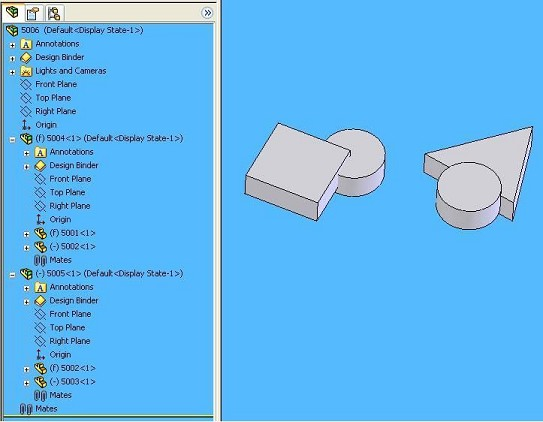

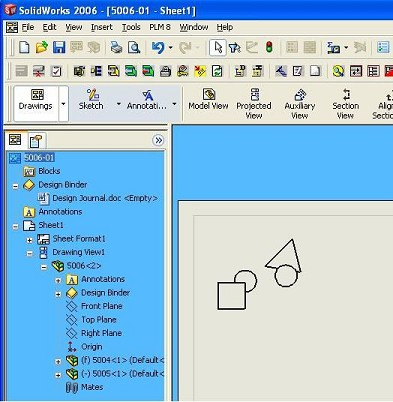

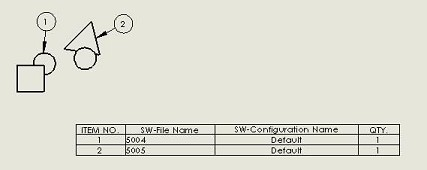

- Create a drawing, Example 5006-01.slddrw for the main assembly 5006.sldasm, as shown

below:

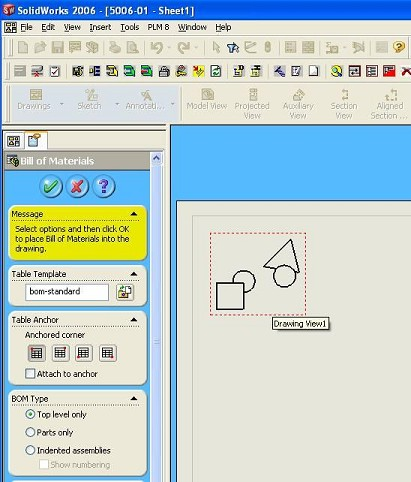

- Select a view.

- To create a BOM table, click Insert > Tables > Bill of

Materials.....

Ensure that in the BOM Type group box, the Top

level only option is selected.

Ensure that in the BOM Type group box, the Top

level only option is selected. - Click OK

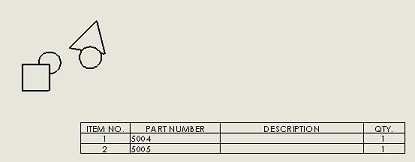

- Click on a point to insert the BOM table; the BOM table is inserted as follows:

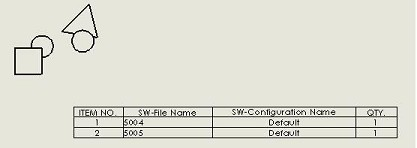

- Change the column description to display the file name and configuration name, as shown

below, if required:

- Select the view.

- To perform auto-ballooning, click Insert > Annotations > Auto-Balloon.....

- Click OK. The top-level components are ballooned as shown

below:

The properties are updated with the following values:

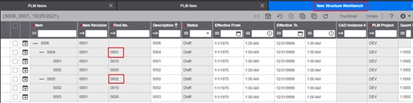

- .Perform the Save to PLM operation for the drawing. The target field in PLM (of the Part

List table) is updated with the balloon value. In the current example, the target field is

FIND_NO. The FIND_NO is updated with the

balloon-ids.

To update the find numbers for the child components of the sub-assemblies, namely, 5004.sldasm and5005.sldasm, you must create drawings, repeating the above process.