Transportation time for linked assembly lines

A supply line linked to multiple parent lines, can be physically present in the

same geographical location as the parent lines or can be located in a different

geographical area. If the supply line is located in a different geographical

area, the time to transport assembled components to the parent line must be taken into account when planning the assembly orders.

Note

The transportation time for the supply of assembled components

between the supply line and parent lines must be defined for multisite assembly scenario as well as the single site

assembly scenario. The assembly lines must be logically linked in the assembly

line network structure.

Example

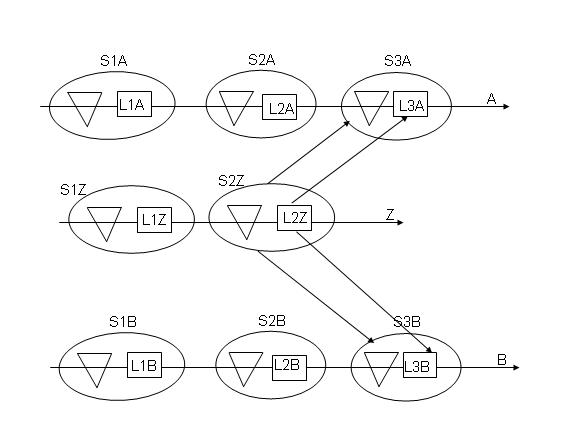

The following example shows a supply line which is linked to

two different parent assembly lines.

The tranportation time is calculated based on the

following:

To calculate the transportation time, you must link the last line station of the last line segment of the supply line to a line station on a parent assembly line.

In the above example, the last line station L2Z of the last line segment S2Z

can be linked to L3A on main line A and/or to L3B on main line B.

You must define the address for the linked line stations and use

the distance tables in Freight to calculate the transportation time.

Note

If multiple supply lines are linked to the same line station

on the parent assembly line, each supply line-parent line combination can have their

specific transportation time.

Important!

The transportation time is displayed only on the line station

order related to the last line station of the last line segment on a supply line.

The transportation time is taken into account for the following

processes:

Generating Assembly Orders: When assembly orders are generated, line station orders (LSO) are also generated. The Planned Transport End Date of the line station order related to the last line station of the supplying line, is

set to the start date of the assembly order. The Transport Time is set to zero.

Offsetting line station orders where the Assembly Order Status is Created: Offsetting line station orders is based on the

transportation time and the defined line segment lead time offset . The Planned Transport End Date of the line station order

related to the last line station of the supplying line is set to the end date

of the line station order. The value of the Transport Time field is set to zero.

Offsetting line station orders where the Assembly Order Status is Sequenced: Offsetting the line station orders on the

supplying line is based on the transportation time in order to determine the

start time and end date of the line station orders on the supply line. The Planned Transport End Date of the last line station

order on the last line segment of the supply line is set to the Planned Start Time of the linked line station order

on the parent line. The Transport Time is calculated using the following

formula:

Planned End Time - Planned Transport End Date

While calculating the transport time, the values

from the last line station of the last line segment of the supply line are

considered.

Line sequencing: The transportation time is taken into

account during the Synchronizing Supplying Lines process for assembly orders

with the Sequenced status. The start time of the (LSO) of the line station on the parent line is offset with the transportation time

to determine the end date of the LSO of the last line segment of the supplying

line. In case of a multi-site assembly model, this end date on the last line

station order is equal to the offline date of the assembly order, on the

supplying line.

Determining segment schedules: The transportation time is taken into account when segment

schedules are calculated. The transportation time is used to offset line

segments when the dates at which the assembly parts are required, are

calculated.