To generate maintenance planningUse the Generate Maintenance Plan (tsspc2200m000) session to generate maintenance planning. You can plan maintenance activity for the installation group and serialized item that the service organization manages. You can schedule and display the activities in the Planned Activities (tsspc2100m000) session. The maintenance planning provides the maintenance activities that must be carried out in the long term. The operational planning of the maintenance activities is based on the service order planning. All the operational (service) activities are carried out by means of service orders. How to generate maintenance planning Step 1. Service contract If any service contract is active for the Installation group, the planning is not generated for that Installation group. Step 2. Serialized items Select all top serialized items that are active during the specified Date-From and Date-To period. If the Date-From is earlier than the start date of the top serialized item, the Date-From becomes the start date. If the end date of the top serialized item is later than the Date-To, the Date-To becomes the end date. Step 3. Planned Activities The planned activities are generated for the serialized items that are valid between these two dates. LN also generates the planned activities for the child serialized items that are related to the top serialized item. The child serialized items must also be valid. Step 4. Usage Class The usage class that you must use when planned activities are generated is selected in the following order:

Step 5. Reference Activities LN checks if reference activities linked to the item are present. If present, the reference activities are used to generate the planned activities. Step 6. Maintenance Cycle The maintenance planning can be carried out in three different ways, based on the start of the maintenance cycle:

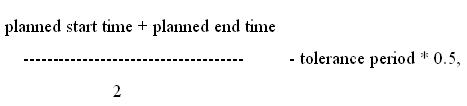

The relative movements are transferred into the actual dates based on the value of the Maintenance Cycle field in the Items - Service (tsmdm2100m000) session. After receiving the start date, the first workable date receives the actual planned start date. The activity duration is added to this date to determine the end date.. To find the first workable date and plan forward, the search path for calendars is:

Earliest start time = For each planned activity that is generated, the requirement lines are copied from the Reference Activity - Resource Requirements (tsacm2120m000) session to one of the following sessions:

Process Report: List of planned activities generated. Error Report: List of errors. Defaults:

| |||