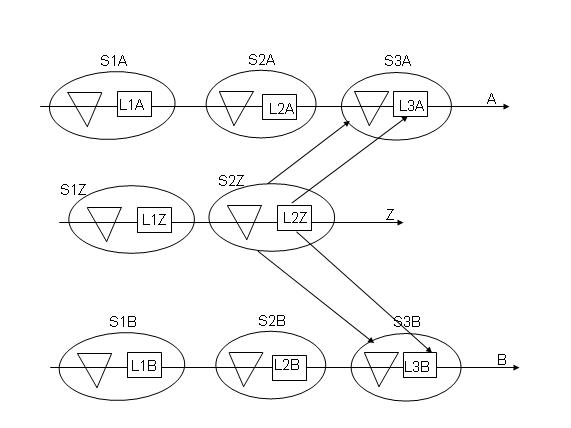

Linking a supply line to multiple parent lines (Divergent assembly line structure)In the current business scenario, the Original Equipment Manufacturers (OEMs) are increasingly beginning to operate on a global scale. This means that a end product can be assembled at one geographical location and its components can be assembled at one or multiple geographical locations. After the components are assembled, they are transferred to different locations where the final assembling of the end product takes place. To model this requirement, you can set up a divergent assembly line structure in LN. In divergent assembly line structures, you can link one assembly line to multiple assembly lines. Example In the divergent assembly line structure, as modeled in the figure below, one supply line is linked to multiple main assembly lines. In our example, the supply line E is linked to main lines A and B. The supply line F is linked to main lines B and C. The supply line F is located in a different geographical area with respect to main line B. ![[...]](../images/tr_diagram_divergentassemblylines000540.jpg) Note The lines can physically reside in different geographical locations, but are logically linked to one assembly line structure. Important! You can model divergent assembly lines for both multisite as well as single site scenarios. In a multisite assembly scenario, you can define a divergent assembly line structure in the master company, and replicate the structure to the other companies. Linking a supply line to multiple parent lines You must link a supply line to parent lines at the following two levels: Example The following example shows a divergent supply line structure in which a supply line is linked to two different parent lines.  Supply Line z linked to main lines A and B

Linking the supply line to a line segment On the line segment level, you can link the last line segment of the supply line to line segments located on different parent lines. In the above example, the last line segment (S2Z) on the supplying line Z can be linked to both line segments S3A on main line A and S3B on the main assembly line B.

Note

Linking the supply line to a line station On the line station level, you can link the last station of the supply line to line stations located on different parent lines. In the example above, the last line station L2Z of supply line Z can be linked to both line station L3A on main line A and station L3B on main line B.

Note

Linking a supply line to multiple supply lines You can model an assembly line network with the following types of supply line structures:

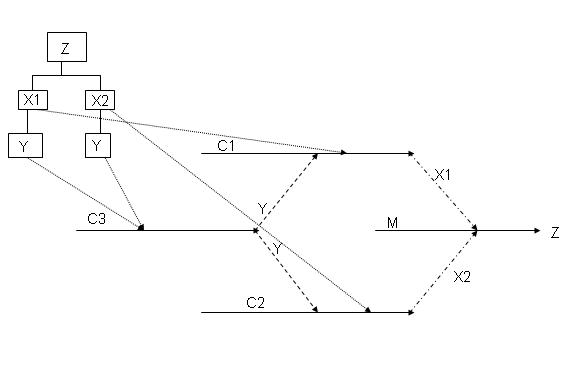

Note You cannot model a assembly line structure with parallel assembly operations. During configuration of an item, when a user selected a product model in which the routing of subassemblies is determined based on the configuration of the assembled main item (the assembled end item can use for example, either part X1 or part X2, which are supplied by two different assembly lines), the definition of an assembly line network model that has assembly lines modeled in parallel is allowed . Then, after configuration, when the routing is determined, a check is performed to determine that the selected routing does not contain assembly lines which are modeled in parallel. If assembly lines that are modeled in parallel are found, the system indicates that the specific assembly structure cannot be generated. As a result, the specific configuration cannot be built. Example In this example, the assembled end item Z must contain either sub-assembly X1 or X2 supplied by different assembly lines.  Parallel assembly operations- Permitted only

during item configuration

The figure above represents an assembly line structure in which two lines are modelled in parallel. Based on the selected configuration of the assembled main item Z (whether Z contains X1 or X2), either supply line C1 or C2 is included in the assembly line network model. You cannot select more than one line when lines are modelled in parallel.

Important! A supply line can be included or excluded by the system only when the Configuration Dependent check box is selected for a supply line in the Assembly Lines (tiasl1530m000) session. For more information, refer to Assembly line selection— Configuration Dependent parameter Divergent structure and Assembly Orders - Unique link Divergent supplying line structure allows you to link a supply line to multiple parent lines. However, the assembly orders on the supply line must still refer to a single assembly order on a parent line, at any given point of time. The supply line can supply an item to different parent lines but a unique reference link is maintained between the assembly orders of the supply line and the assembly orders of the parent lines. Note A single assembly order on a supply line cannot have reference to multiple assembly orders on different parent lines. Example Please refer to the figure for assembly order numbers. ![[...]](../images/tr_diagram_divergentassemblylines000540.jpg)

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||