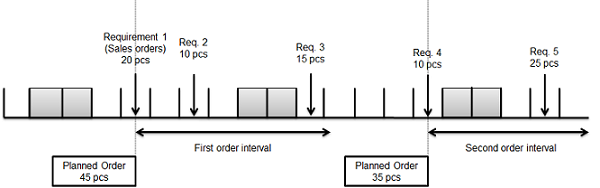

| | Item - Ordering (tcibd2100s000)Order interval is the minimum time interval (in days or hours)

between two successive planned orders. The time interval is measured starting at the last generated

order. Example If the order interval is a week and the first requirement

falls on a Monday, the first order generation moment lies on that

Monday. The system will not generate the second planned order before

the next Monday. However, if there is no need to generate an order on that next

Monday, then the next generated order determines the start of the new order

interval. Some fields in the Item - Ordering (tcibd2100s000) session are explained in the following

table. | Item ordering data |

|---|

| Field | Description |

|---|

| Order Policy | If this field is Anonymous, the item is made to stock (not ordered for a

specific customer or project). If this field is To Order, the item is a project item (ordered for a specific customer or

project). For more information, refer to the documents on Engineer-to-Order, Assemble-to-order, and Make-to-order

order policies. | | Critical in Planning | If this check box is selected, the item is critical in the production process. The

item is by default part of the Bill of Critical Materials (BCM). | | Warehouse | The default value for the warehouse for the plan items based on

this item. | | Reorder Point | This field is not used in Enterprise Planning. | | Service Level [%] | This field is not used in Enterprise Planning. | | Safety Stock | The quantity that is planned to remain available in

inventory at times when the stock is low. The purpose of the safety stock is to

avoid that the item becomes out-of-stock if the demand is higher than

expected. In the master-planning process, Enterprise Planning uses the

safety stock to generate the inventory plan. The inventory plan is subsequently

used to generate the orders. In the order-planning process, Enterprise Planning uses the safety stock directly for

the generation of orders. | | Safety Time | A time period (expressed in hours or days) that is added to the

lead time as part of the lead-time offset in Enterprise Planning. For

more information, refer to the topic document on lead times. | | First Allowed Order Date | This field is not used in Enterprise Planning. | | Order Costs | This field is not used in Enterprise Planning. | | Planner | This field is not used in Enterprise Planning. You can

define a plan item’s planner in Enterprise Planning. | | Shop Floor Planner | This field is not used in Enterprise Planning. | | Seasonal Pattern for Safety Stock | This field affects a plan item’s inventory plan. | | Seasonal Pattern for Forecast | The seasonal pattern for forecast affects the demand forecast

calculation. | | Number of Periods | This field is not used in Enterprise Planning. | | Net change date (display-only field) | The last time on which production orders, demand data,

BOMs, routings, bills of critical materials, or bills of critical capacities

have changed. Enterprise Planning uses the value of this field if you execute a net-change

planning run. | | Net change flag (display-only field) | If this check box is selected, a change occurred in the static data or

in the goods flow. In the next planning run, Enterprise Planning must

take these changes into account. The net change date tells you from where the planning

should be run. Before the net change date, the system does not have to

re-execute the planning calculations, because no changes occurred there. If you

execute a planning run, Enterprise Planning clears the check box. | | Update Inventory/Order Data | This field is not used in Enterprise Planning. | | PCS Project (Recommended OQ, OQ) | This field is not used in Enterprise Planning. |

| |