Item - Ordering (tcibd2100s000)Order System Enterprise Planning only plans items of which the order system is Planned. To specify the order system:

Lot sizing A planned order’s order quantity is the quantity that is manufactured, bought, or otherwise supplied by that planned order. The value of the Order Method field determines which rules Enterprise Planning applies in the order quantity calculation. General lot-sizing parameters:

Parameters for specific order methods:

To avoid orders for unusual quantities (for example, 32,142 iron bolts), set the Order Quantity Increment field to round numbers, such as 10, 50, or 100. Enterprise Planning plans the order quantity to a multiple of the Order Quantity Increment field. To avoid orders for extremely small quantities (for example, 20 inch of metal wire), set the Minimum Order Quantity field to a reasonable value. Very large orders reduce the planning flexibility for your production and handling facilities. For example, a production order that keeps a work center occupied for three weeks, prevents the system from scheduling small rush orders in between. To prevent these situations, use the Maximum Order Quantity field. The Order Method field can have these values:

Lot-for-Lot The most simple order method is Lot-for-Lot. If the order method is Lot-for-Lot, Enterprise Planning calculates the order quantity as follows:

Note If the maximum order quantity constraints the order quantity, the system optimizes the generated orders. Example

Two orders are created of 35 pieces. The system does not generate an order of 50 and another order of 30, because this would result in 10 pieces too much. Fixed order quantity If the order method is Fixed Order Quantity, Enterprise Planning always makes the order quantity equal to the fixed order quantity, as follows:

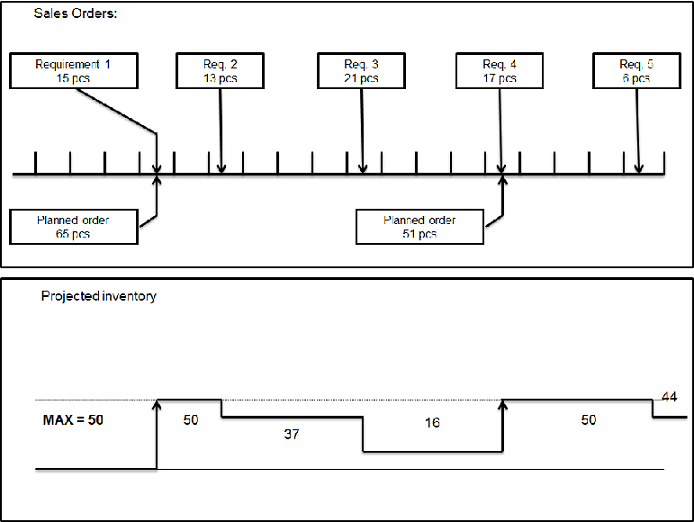

Economic order quantity The economic order quantity is the lot size that will give you the lowest total cost, considering order costs and inventory handling costs. To calculate the economic order quantity, click Calculate EOQ. If the order method is Economic Order Quantity (EOQ), Enterprise Planning sets the order quantities to at least the economic order quantity. Replenish to maximum inventory If the order method is Replenish to Maximum Inventory, Enterprise Planning generates orders if the projected inventory drops below the inventory plan or the safety stock. If this happens, the order quantity is made large enough to bring the inventory back to the maximum inventory level. You can set the maximum inventory level in the Maximum Inventory field. The Replenish to Maximum Inventory order method is particularly suitable if:

Example

Replenish to maximum inventory

In previous LN versions, this order method was implemented for SIC (Statistical Inventory Control) items). The functionality is available for planned items as well. You can apply the SIC logic during the order generation run.

| |||