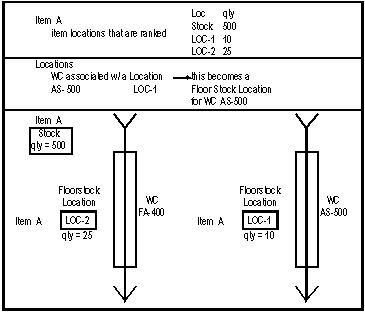

Example: Floorstock Replenishment

The top portion of the diagram illustrates the locations and quantities for Item A. The stock location has a quantity of 500 and Loc-1 has a quantity of 10, while Loc-2 has a quantity of 25.

The middle portion of the diagram illustrates the relationship of the item location and the work center. In this case, Loc-1 is associated with work center AS-500.

The bottom portion of the diagram illustrates two assembly lines for Item A. The assembly lines are running through two different work centers and each work center has its own floor stock location, and therefore, its own available, on-hand quantity.

- If you want the system to consider a floor stock location when you run this report, you cannot designate the location as a transit or non-nettable location. See Item Stockroom Locations for more information.

- The quantity in the item location that is considered available

for replenishment purposes is the difference between the on-hand quantity

less any reserved quantity.

AQ = OHQ - RQ

where:

- AQ = Available Quantity

- OHQ = On Hand Quantity

- RQ = Reserved Quantity

- The Net WC/Floor Location Qty Avail option allows you to include or exclude the current quantity in the floor stock location. In this case, when running the report for WC - AS500, you could include or exclude the quantity of 10 from LOC-1 when calculating the new requirements.

- The report suggests floor stock replenishment requirements only for those locations associated with a work center. In this example, if you ran the report for WC - AS500, the report would suggest requirements for LOC-1 only.

Note: In this scenario,

we are assuming that you have run the Floor Stock

Replenishment Report only for AS500. You can run the report for

all work centers.