Creating Sub-Jobs

You might want to create sub-jobs if you need to maintain this job-supply linkage for reference purposes or for visibility on reports such as the Indented Projected Job Cost to Complete report or Consolidated Job Cost report. This topic describes how to create sub-jobs automatically for each subassembly in a bill of material, using a common job ID structure.

Creating a Sub-Job through Cross-Referencing

You can create an individual sub-job automatically by cross-referencing a job material.

See Creating a Sub-Job through Cross-Referencing.

You can also create sub-jobs for a range of parent jobs through cross-referencing using the Material Planner Workbench Generation. With this method, the parent job must be a scheduled job.

Generating Sub-Jobs Automatically

To allow the system to create sub-jobs automatically, you can perform one of these tasks:

- Use the Copy Routing/BOM or Engineering Workbench form to copy a routing and bill of material to a job, and select the Copy Indented BOM field. See Copying Routings/BOMs for more information.

- Use the Planning Detail or Material Planner Workbench form to firm a planned order into a job, and select the Copy Indented BOM field on the Firm Job dialog.

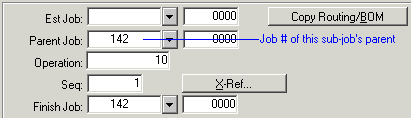

The system creates a sub-job for any current subassembly material within the BOM that has a Reference of Job (the Reference field on the Current Materials form). Generated sub-jobs will use the job number of their parent job + an incremented Job Suffix number. For example, if parent job 142 has two sub-jobs, the sub-jobs will be numbered 142-0001 and 142-0002.

Managing Sub-Job Start and End Dates

When you create the sub-jobs automatically, as described above, their start and end dates are defined based on the planning mode you are using:

- APS Planner: If the Use Scheduled Times in Planning field is not selected, the job start and end dates are sent to the planner for planning. The planner attempts to plan sub-jobs to meet the dates supplied during the copy (instead of "today"). If the Use Scheduled Times in Planning field is selected and the job is scheduled, then the scheduled dates are sent to the APS Planner.

- MRP Planning: If the Use Scheduled Times in Planning field is not selected, then the MRP Planner uses the job start and end dates initially supplied during the Copy BOM activity. If the Use Scheduled Times in Planning field is selected and the job is scheduled, then the scheduled dates (projected) are used.

- APS Scheduler: The APS Scheduler attempts to forward schedule from the job's start date.

See About Job Dates for more information.

Finding a Sub-Job's Parent Job

On the Job Orders form, filter to a sub-job and select the References tab to view this sub-job's parent job.