You can use the Engineering Workbench to add a routing

and bill of material to inventory items (the current routing), production

schedules, jobs, or estimate jobs. If you're using the Molding Pack, you

can also add a routing and bill of material to co-product jobs or co-jobs.

-

To select the transaction:

-

In the View field, select the

type of routing/BOM to work with.

-

Click the filter button in the toolbar.

-

Use the header fields to select the item, job, or production

schedule to which you want to add routing/BOM information.

-

Click the filter button again. Any existing routing information

for the item, job, or schedule is displayed.

-

To create the routing:

-

In the Operations grid, add a new record for each new operation

in the routing. Use the grid fields to select a work center and

define operation setup, queue, and run times, as well as the start

and end date and other information about the operation.

-

After adding all the operations for the routing, select .

-

If you need to define resources for an operation beyond the

default resource group defined for that operation's work center:

- Right-click on the operation number in the Operations grid

and click Details. The appropriate

Operations form opens, with the record for this operation

displayed.

- In that form, select the Resources

tab and define the crew or machine resource groups that this

operation requires in order to be processed, as well as parameters

related to the resource groups.

- Save the record and close the form.

-

If you need to define costs for an operation:

- Right-click on the operation number in the Operations grid

and click Details. The appropriate

Operations form opens, with the record for this operation

displayed.

- In that form, select the Costs

tab and define the values used in costing this operation.

- Save the record and close the form.

-

To add materials:

The Engineering Workbench record containing

a new operation must be saved before you can add materials for the

operation.

-

In the Materials grid, add a new record. Select an operation

for which you want to define a material. Then select or enter

the rest of the information about the material. You can add multiple

lines defining different materials for a single operation.

-

Once you have added all the materials for the operations you

defined, select to

save the new materials.

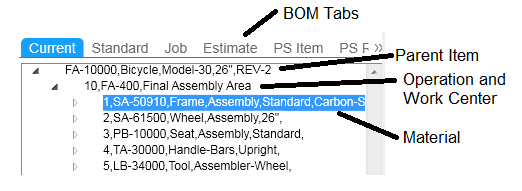

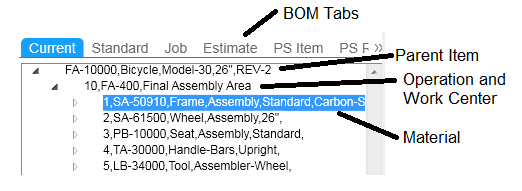

You can now viewing the new routing/materials in the left tree pane

of the Engineering Workbench form. The pane

contains a tab for each of the available routing/Bills of Material.

To see the new operations or materials you added, either close and reopen

the Engineering Workbench form, or click

the filter button on the left pane and click OK

in the dialog that appears. Either method refreshes the tree pane.

The tree display is shown here:

You can collapse the tree display into a simpler view

by selecting the (-) symbol next to each item or operation. For example,

suppose you want to look at operations for the item, without displaying

the materials. Click the (-) symbol next to the operation, and the materials

disappear in the collapsed tree. The word "Alternate" appears

next to any material that is specified as an alternate material on a current

operation.

Note: You cannot

add or remove operations or items from routing/BOMs in the left pane.

Use the right pane of the Engineering Workbench

form for maintaining routing/BOMs.