Example: Adjusting the Production BOM for Phantom Inventory Usage

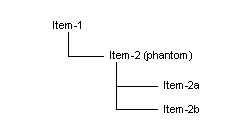

Consider this current routing/BOM:

- There is a customer order for Item-1 for a quantity of 8.

- You have 4 of Item-2 on hand.

- Item-2, Item-2a, and Item-2b are all defined with Qty/Per values of 1 per unit.

To adjust the production BOM for this example, follow these steps: