Put away overview

The put away task is initiated when inventory is received. Put away is facilitated by pallet ID labels. Pallet labels are generated with a unique nine-digit number that begins with P. The labels can be fastened to the pallets before the truck arrives, or as the goods are unloaded. After the pallet IDs are attached to the pallet and scanned, the pallet cannot be used for another purpose until contents are put away. Another purpose may be shipping or picking.

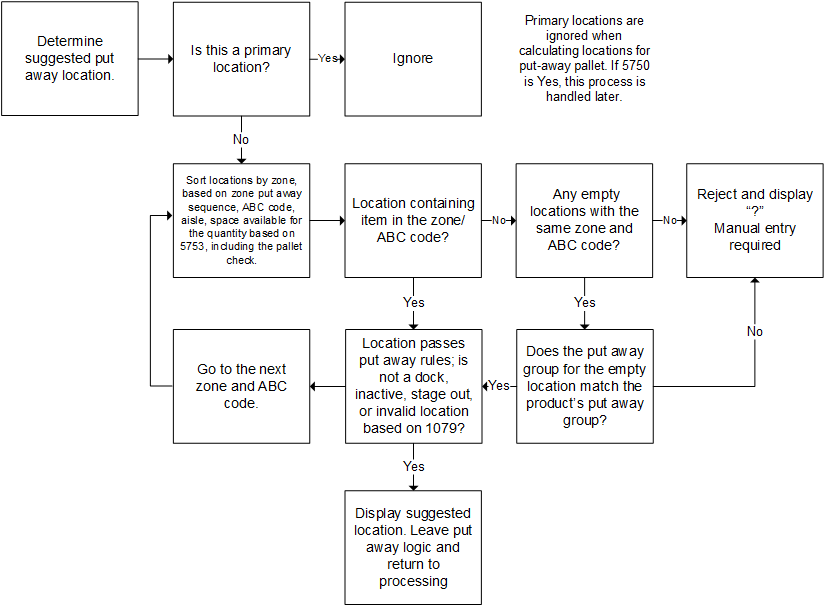

TWL system logic is used to search for a location in a zone that already contains the product. The location must also match the zone that is identified on the TWL Configuration-Item master record. If a location with existing inventory is not found, the system logic is used to search for empty locations in the same zone and ABC code as the product. If an empty location is found, then the system logic is used to compare the put away groups on two records. The records are the TWL Configuration-Item master and TWL Configuration-Location master record.

This table shows how the put away groups are compared:

| ABC code | Search order |

|---|---|

| A | ABCD |

| B | BCDA |

| C | CDBA |

| D | DCBA |

Depending on the comparison, these factors affect the put away process:

-

If a suitable location is found, then established rules are applied, such as location constraints, product restrictions, and zone restrictions. Additional factors, such as top-off replenishment and open receipt transactions (RT) are considered by the system logic.

After a location is determined, parameter settings are checked by the system logic. A location for put away is not suggested if these factors exist:

- If parameter 7506, Allow Multiple Lots Per Location/Pallet, is set to No, and the lot does not match the existing lot in the pallet location

- If the product status does not match the status of inventory in the location

The suggested location is displayed on the RF unit.

-

If a suitable location is not found, then a question mark (?) is displayed on the RF unit. You can manually choose a put away location.

Note: Do not attempt to put away an item with no suggested location to a warehouse zone that does not allow put away. Otherwise, an error is displayed: Whse Zone XX does not allow put away. Please select another location.

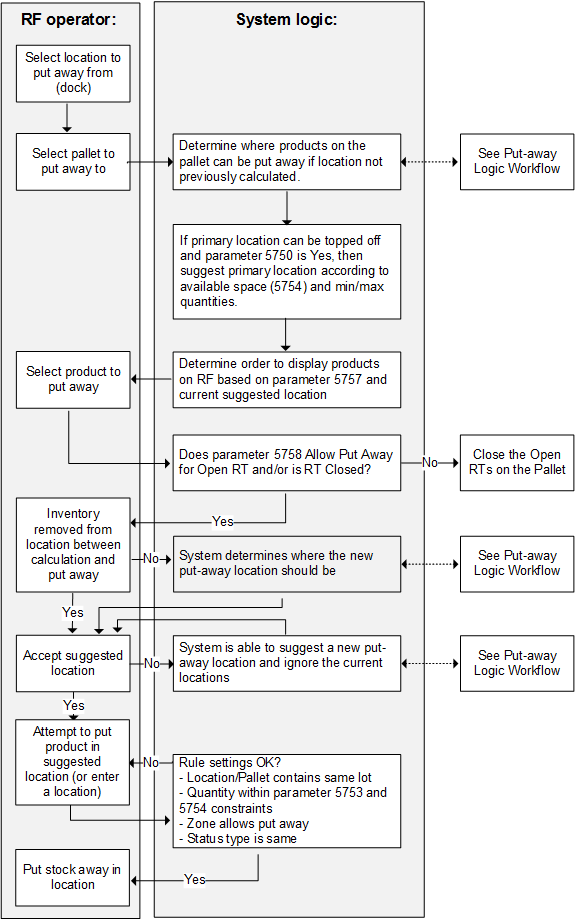

This workflow shows what is done by the RF operator during the put away

process, and what is done by the TWL system.

This diagram shows the high-level put away logic workflow:

This diagram shows what is done by the RF operator during the put away process,

and what is done by the TWL system: