Transfer shipping

The order is set to shipped stage when the WL Entry Batch Shipping Reportis run. Backordering is also handled. The shipped date, package count, ship via, and actual freight are updated. Warehouse transfer lines that are zero shipped change the transfer back to Stage 1 (Ordered) and the lines are put on hold.

Your TWL administrator can use the

WT Order Exception Report and set the Not Approved Line Items option to

Yes to identify the zero shipped lines. If the

lines are approved, you can reprint the transfer and resend the order to TWL. Warehouse transfers that are zero shipped are

processed in the same manner that Sales Order Entry

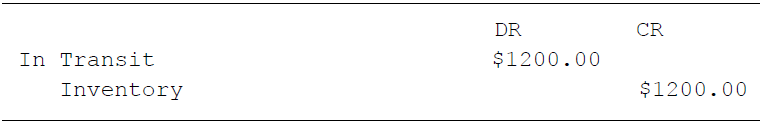

orders are handled. This graphic shows the General Ledger entries that are made for the

transfer:

When a transfer is shipped from a TWL warehouse and an exception occurs, the Transfer Exception Receipt Entry function is used to resolve the exception. The Transfer Exception Receipt Entry exceptions are always adjusted in the shipping warehouse because the receiving warehouse has possession of the inventory and can verify the errors.

If a shipment is received short, then short-ship information is displayed in the Transfer Exception Receipt Entry for the shipping warehouse. A message is displayed: WL Quantity Received < Shipped; Press Space Bar to Update (6513).

This graphic shows the General Ledger entries that are created by the Transfer Exception Receipt Entry. It also shows that the

Product Warehouse Product Setup In Transit

quantity is adjusted accordingly:

A stock adjustment, which is initiated from TWL, is the only type of transaction that is used for short shipments.

A Transfer Exception Receipt Entry cycle count request is created in TWL for the shipping warehouse. This action checks the quantity in the location where the transferred product was picked. The Transfer Exception Receipt Entry cycle count request is created because the receiving warehouse initiates the discrepancy. Use the TWL system to count the product with the discrepancy and to initiate a stock adjustment.

If there is no inventory in the location, a Transfer Exception Receipt Entry cycle count wave is also created, so that the empty location can be verified. Quantity in Distribution SX.e is adjusted when the stock adjustment is uploaded from TWL.

This graphic shows that General Ledger is adjusted when the stock adjustment is

processed through the WL Entry Batch Adjust Inventory

Report. It also shows that the WL Entry Batch

Adjust Inventory Report creates the General Ledger entries for a

shortage:

If the receipt is for a greater quantity than the shipment, then the over-receipt information is displayed in Transfer Exception Receipt Entry. A message is displayed: WL Quantity Received > Shipped; Press Space Bar to Update (6024)

This graphic shows the General Ledger entries created by the Transfer Exception Receipt Entry. It also shows that the

Product Warehouse Product Setup In Transit

quantity is adjusted accordingly:

A stock adjustment, initiated from TWL, is the only type of transaction that can be used for an overage. A cycle count request is synchronized from TWL to the shipping warehouse to check the quantity in the location from which the transferred product was picked. The cycle count request is synchronized because the receiving warehouse initiates the discrepancy.

The TWL warehouse is responsible for

counting the product with the discrepancy and initiating a stock adjustment. The system

is adjusted when the stock adjustment is synchronized from the TWL warehouse. This graphic shows the General Ledger is adjusted

when the stock adjustment is processed through the WL Entry

Batch Adjust Inventory Report. It also shows that the WL Entry Batch Adjust Inventory Report creates the

General Ledger entries for an overage: